Processing method of fast-cooking coarse cereal porridge material

A processing method and technology of miscellaneous grain porridge, which is applied in food science, food preservation, food ingredients as taste improvers, etc., can solve the problems of low viscosity of porridge and long cooking time, and achieve the effect of nutritional balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

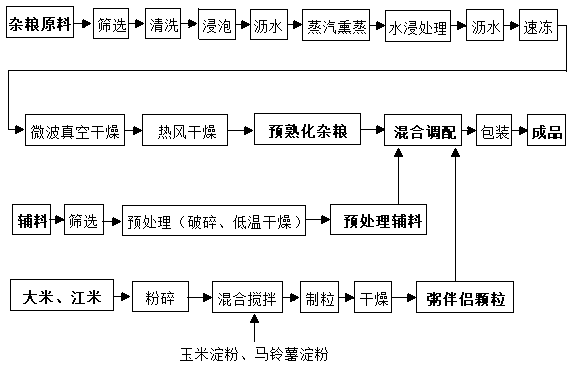

[0053] The quick-cooked multi-grain porridge prepared by the processing method of the quick-cooked multi-grain porridge is boiled for 5 minutes to obtain a convenient multi-grain porridge with a viscosity value of 750mPa·sr. exquisite. Such as figure 1 As shown, the processing method of instant multigrain porridge is as follows:

[0054] (1) Screening of raw and auxiliary materials

[0055] a) Select high-quality miscellaneous grains, rice and other raw materials, and remove gravel, soil clods, heterogeneous grains, insect-eaten grains, imperfect grains, damaged grains, and spotted grains from the raw materials.

[0056] b) Dehydrated jujube grains are used for jujube, square in shape, 1-2mm in size, and 5% moisture content; dehydrated dried yam slices are used for yam, and the moisture content is 4%; dehydrated and dried lotus seeds are selected for lotus seeds, without lotus seed core , with a water content of 4%; lilies are made of dehydrated and dried lily slices with a...

Embodiment 2

[0082] The quick-cooked multi-grain porridge prepared by the processing method of the quick-cooked multi-grain porridge is boiled for 5 minutes to obtain a convenient multi-grain porridge with a viscosity value of 780mPa·sr. exquisite. The processing method of quick-cooking miscellaneous grain porridge is as follows:

[0083] The processing method of quick-cooking miscellaneous grain porridge is as follows:

[0084] (1) Screening of raw and auxiliary materials

[0085] a) Select high-quality miscellaneous grains, rice and other raw materials, and remove gravel, soil clods, heterogeneous grains, insect-eaten grains, imperfect grains, damaged grains, and spotted grains from the raw materials.

[0086] b) Dehydrated jujube grains are used for jujube, square in shape, 1-2 mm in size, and 6% moisture content; dehydrated dried yam slices are used for yam, and the moisture content is 5%; dehydrated and dried lotus seeds are selected for lotus seeds, without lotus core , with a wat...

Embodiment 3

[0112] The quick-cooked multi-grain porridge prepared by the processing method of the quick-cooked multi-grain porridge is boiled for 5 minutes to obtain a convenient multi-grain porridge with a viscosity value of 800mPa·sr. exquisite. The processing method of quick-cooking multi-grain porridge is as follows: The processing method of quick-cooking multi-grain porridge is as follows:

[0113] (1) Screening of raw and auxiliary materials

[0114] a) Select high-quality miscellaneous grains, rice and other raw materials, and remove gravel, soil clods, heterogeneous grains, insect-eaten grains, imperfect grains, damaged grains, and spotted grains from the raw materials.

[0115] b) Dehydrated jujube grains are used for jujube, square in shape, 1-2 mm in size, and 8% moisture content; dehydrated dried yam slices are used for yam, and the moisture content is 6%; dehydrated and dried lotus seeds are selected for lotus seeds, without lotus core , with a moisture content of 8%; lily ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com