Tobacco stick posture correction device and method

A calibration method and a calibration device technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve problems such as blockage and extrusion of tobacco rods, affecting machine operation efficiency, and skewed tobacco rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

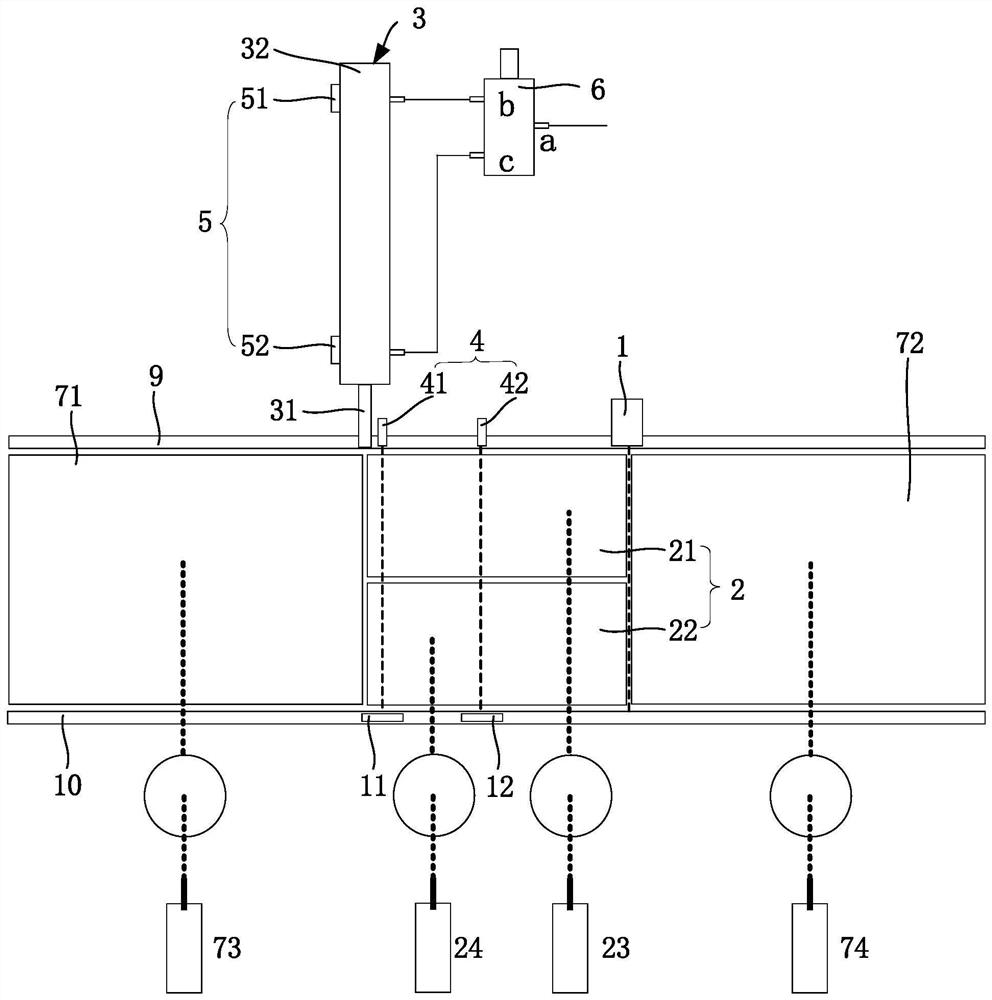

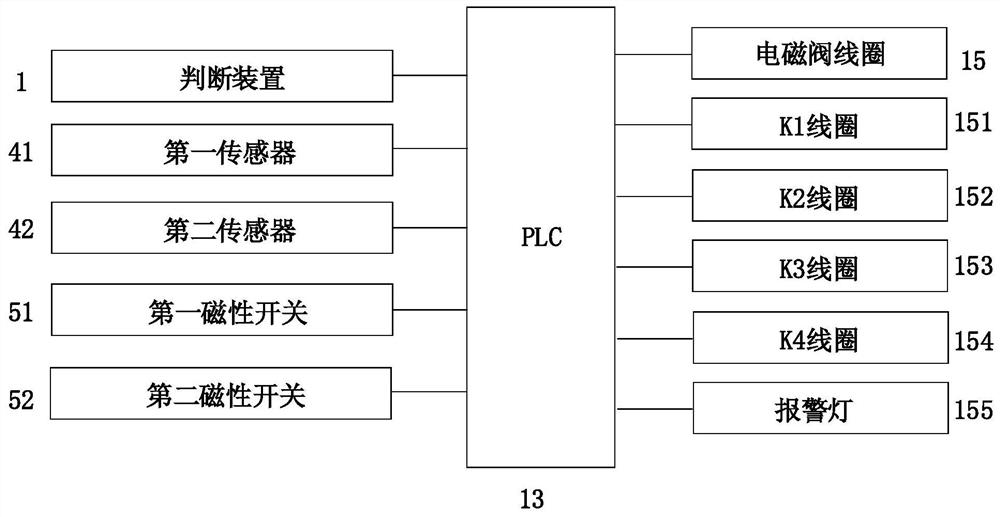

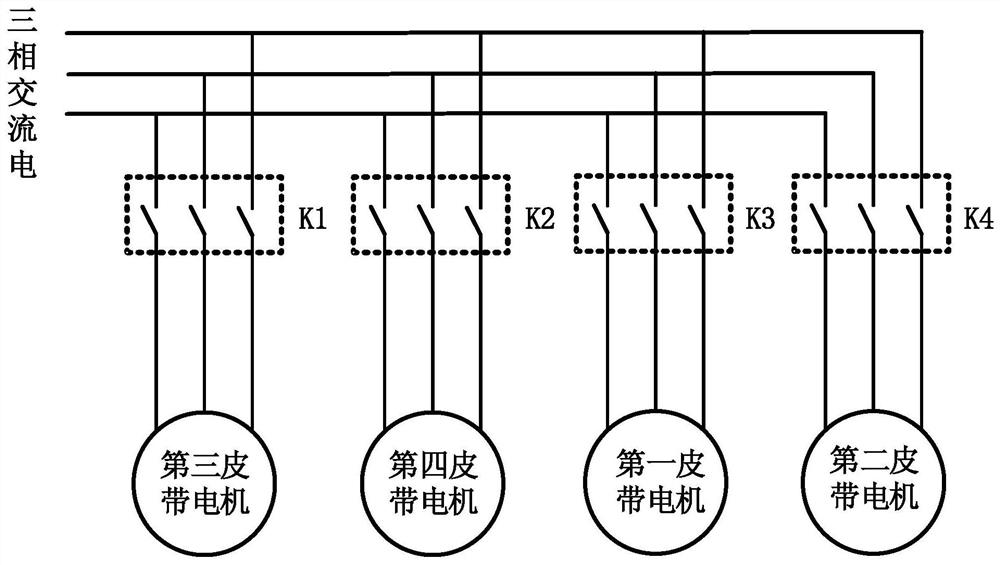

[0082] Combine below Figure 1 to Figure 32 The technical solutions provided by the present invention are described in more detail.

[0083] see figure 1 , the present invention provides a device for correcting the posture of a tobacco rod, including a posture judging device 1 and a correcting device 2 . The attitude determination device 1 is configured to determine whether the tobacco rod 8 is inclined; the correction device 2 is configured to correct the attitude of the tobacco rod 8 when the tobacco rod 8 is inclined.

[0084] The posture judging device 1 uses, for example, a camera, an infrared sensor, an image recognition, a laser displacement sensor, etc. to judge the posture of the tobacco rod 8 .

[0085] The calibration device 2 uses, for example, a manipulator or the like. Specific implementations adopted in some embodiments will be given later.

[0086] see figure 1 , In some embodiments, the tobacco rod attitude correction device further includes a stopper dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com