Automatic pet belt baler

A PET belt, fully automatic technology, applied in the field of automatic PET belt balers, can solve problems such as unfavorable high-speed production of enterprises, optimize production costs, occupy human resources, etc., and achieve the effect of reducing occupation, ensuring packaging efficiency, and optimizing enterprise costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

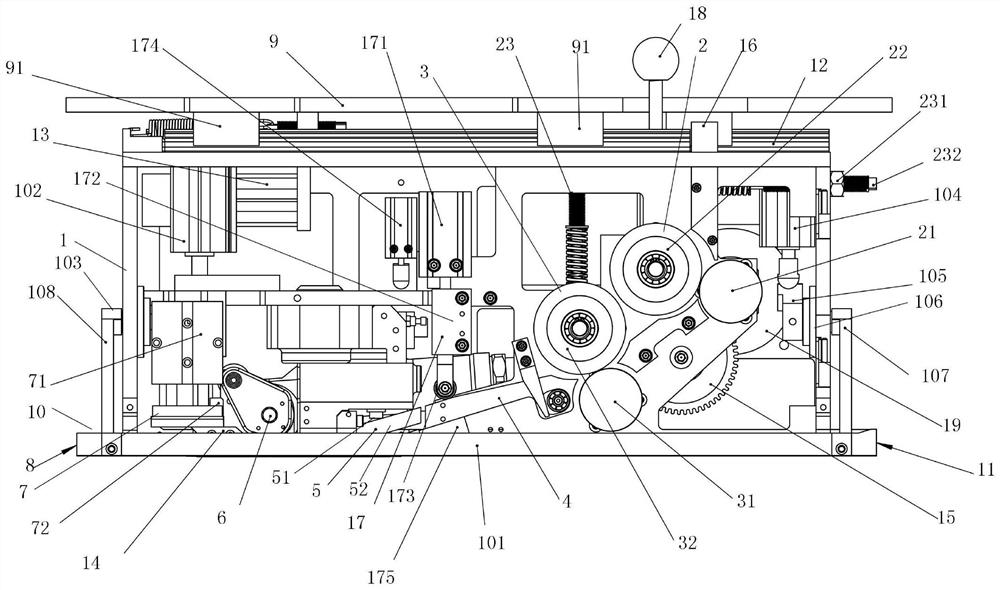

[0021] see figure 1 , this embodiment shows a fully automatic PET strapping machine:

[0022] Including the frame 1, the PET tape entrance 11 arranged on the frame 1, the tape take-up assembly A2 and the tape take-up assembly B3 arranged on the frame 1 and used in conjunction with the PET tape entrance 11, and the tape take-up assembly B3 arranged on the frame 1 and The sliding belt groove 4 used in conjunction with the take-up assembly A2 and the take-up assembly B3, the cutter assembly 5 used in conjunction with the slide belt groove 4, the tension pulley 6 set corresponding to the cutter assembly 5, and the belt position detection device 7 , and the PET belt outlet 8, the top of the frame 1 is provided with a linear slide rail 12, and the linear slide rail 12 is correspondingly connected to the traverse slide block 91 provided on the tight belt lateral movement mechanism 9, and the frame 1 is also correspondingly provided with Tight belt booster cylinder 13.

[0023] Corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com