Soybean protein packaging device

A technology of soybean protein and charging box, which is applied in the direction of packaging material feeding device, packaging, packaging machine, etc., can solve the problems of easy clogging of the hopper, clogging of the feeding pipe, and inability to rotate and stir the hopper, so as to avoid clogging the hopper and avoid errors , to avoid the effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

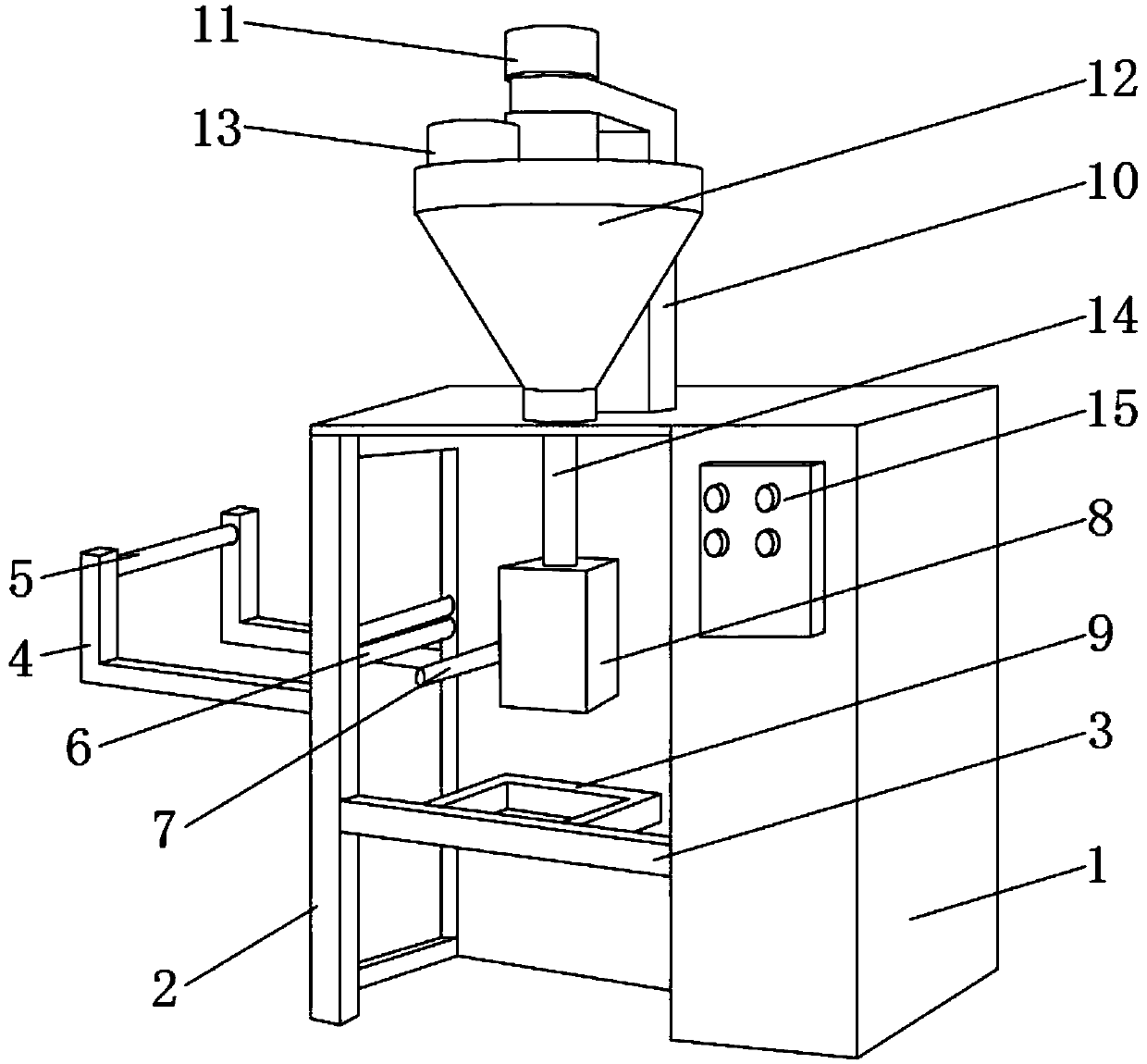

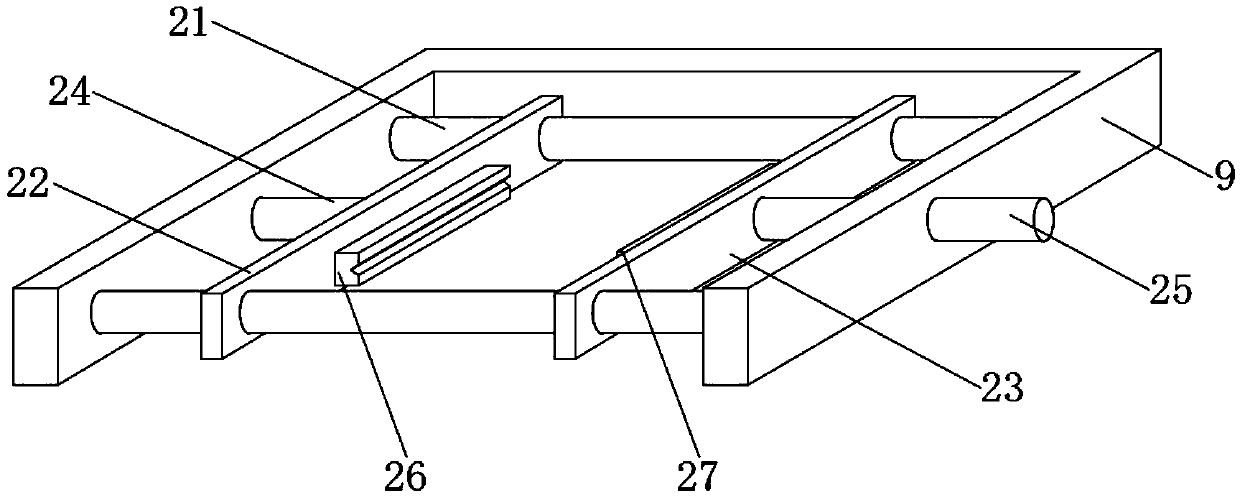

[0027] like Figure 1-5 As shown, a soybean protein packaging device includes a bottom box 1. The shape of the bottom box 1 is L-shaped. One end of the support rod 2 is fixedly installed, and the top of the support rod 2 is fixedly connected with the top plate, and the outer surface of the front end of the bottom box 1 is fixedly installed with a charging box 8 and a sealing frame 9, and the charging box 8 is located at the upper end of the sealing frame 9. And the sealing frame 9 is fixedly connected with the cross brace 3 .

[0028] One side of the bottom box 1 and the support rod 2 is fixedly installed with a bracket 4, the upper end of the bracket 4 is provided with a paper roller 5, a paper clamping device 6 is arranged between the bottom box 1 and the support rod 2, and the front end of the bottom box 1 is set There is a paper feeding roller 7, and the paper feeding roller 7 is located between the paper clamping device 6 and the charging box 8, and a control panel 15 is...

Embodiment 2

[0033] like Figure 1-5 As shown, a soybean protein packaging device includes a bottom box 1. The shape of the bottom box 1 is L-shaped. One end of the support rod 2 is fixedly installed, and the top of the support rod 2 is fixedly connected with the top plate, and the outer surface of the front end of the bottom box 1 is fixedly installed with a charging box 8 and a sealing frame 9, and the charging box 8 is located at the upper end of the sealing frame 9. And the sealing frame 9 is fixedly connected with the cross brace 3 .

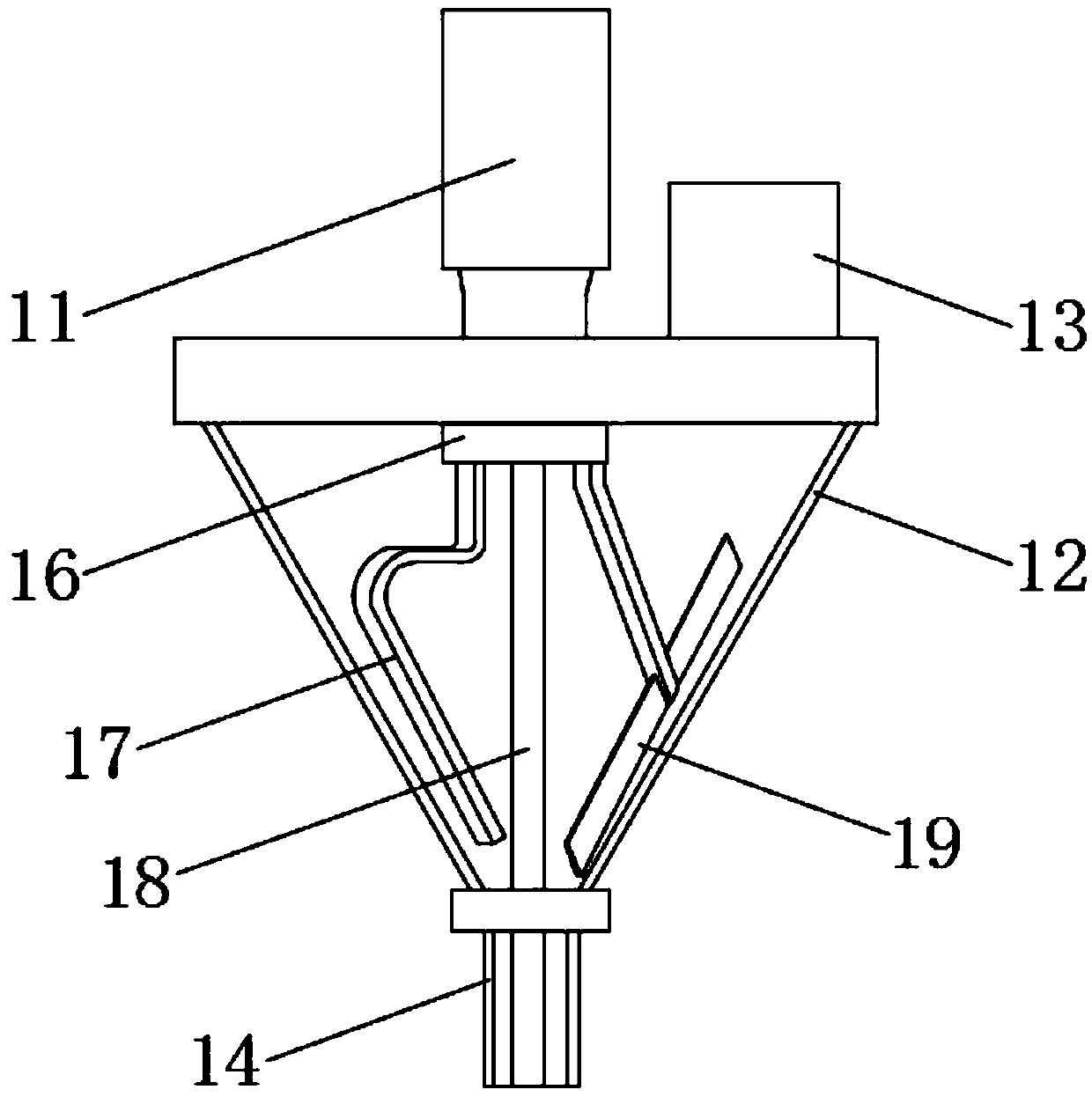

[0034] The upper end of top plate is fixedly installed with installation bar 10, and the upper end of installation bar 10 is fixedly installed with stirring motor 11, and the lower end of installation bar 10 is fixedly installed with hopper 12, and the lower end of hopper 12 is connected with feed pipe 14, and the lower end of feed pipe 14 is connected with The charging box 8 is communicated and connected, and the feeding rod 18 is located in the middl...

Embodiment 3

[0040] like Figure 1-5 As shown, a soybean protein packaging device includes a bottom box 1. The shape of the bottom box 1 is L-shaped. One end of the support rod 2 is fixedly installed, and the top of the support rod 2 is fixedly connected with the top plate, and the outer surface of the front end of the bottom box 1 is fixedly installed with a charging box 8 and a sealing frame 9, and the charging box 8 is located at the upper end of the sealing frame 9. And the sealing frame 9 is fixedly connected with the cross brace 3 .

[0041] One side of the bottom box 1 and the support rod 2 is fixedly installed with a bracket 4, the upper end of the bracket 4 is provided with a paper roller 5, a paper clamping device 6 is arranged between the bottom box 1 and the support rod 2, and the front end of the bottom box 1 is set There is a paper feeding roller 7, and the paper feeding roller 7 is located between the paper clamping device 6 and the charging box 8, and a control panel 15 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com