Aluminum plastic plate edge strip aluminum and plastic separation device

A technology of aluminum-plastic separation and aluminum-plastic panels, which is applied in layered products, lamination auxiliary operations, lamination, etc., can solve the problems of difficult recycling of scrap aluminum-plastic panels, inability to completely separate, and unsatisfactory effects. To achieve the effect of saving manpower, convenient winding and rewinding, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below through specific examples.

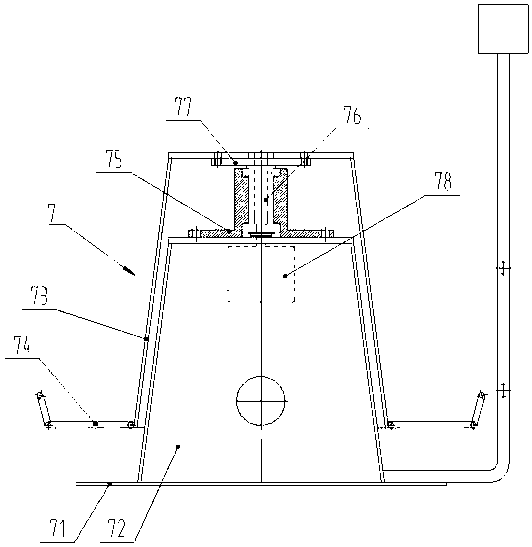

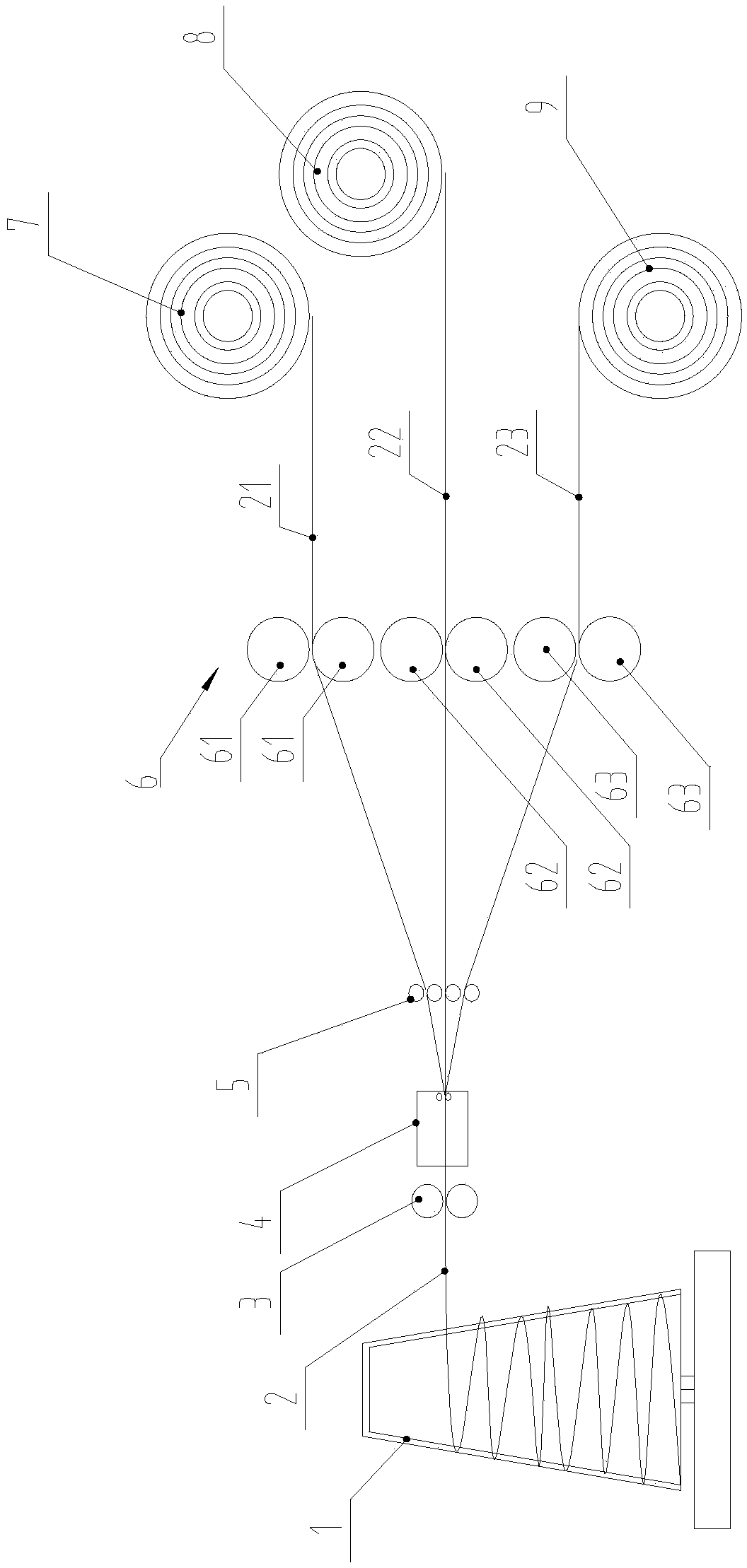

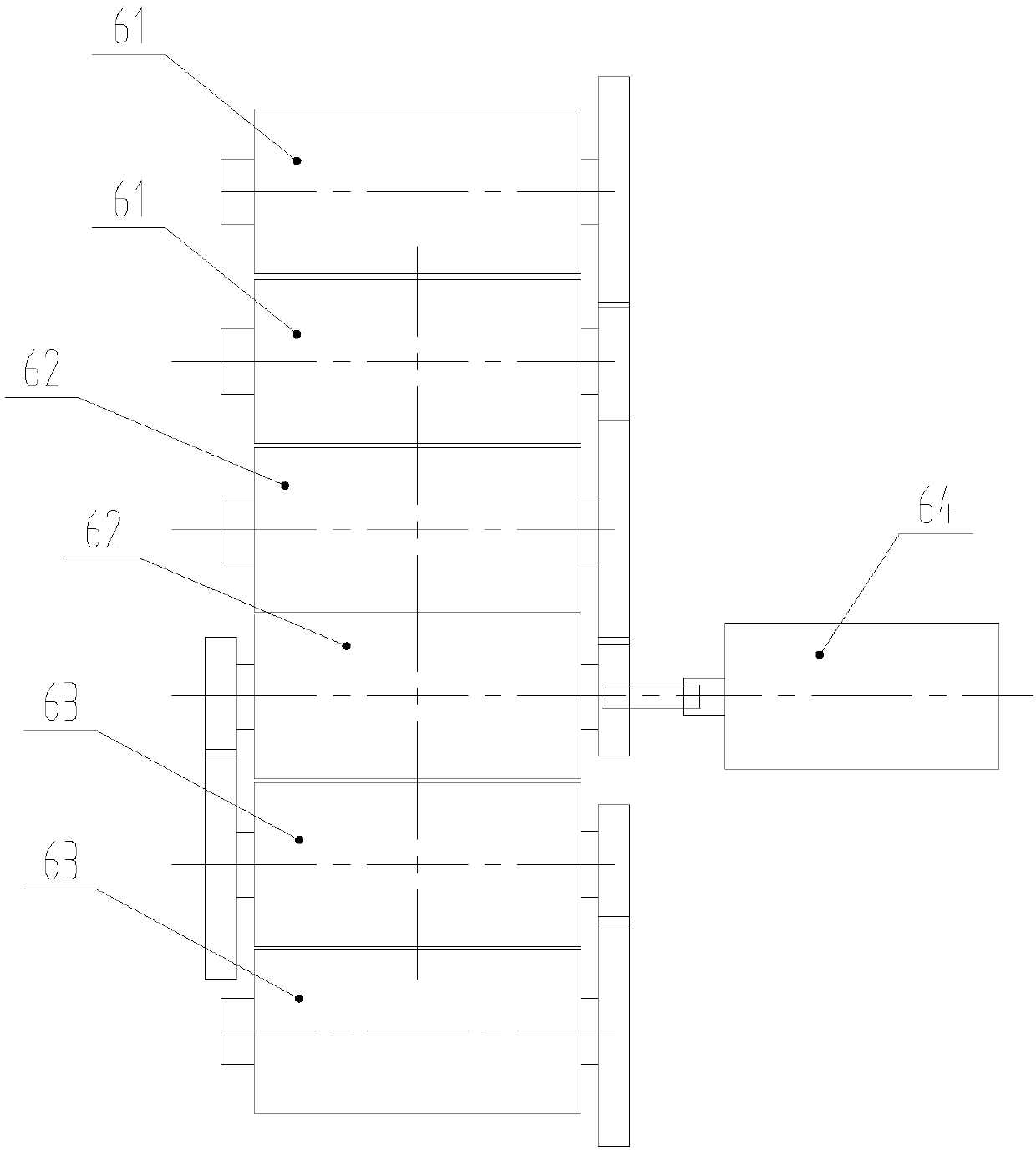

[0029] Such as Figure 1 to Figure 4 As shown, an aluminum-plastic separation device for side strips 2 of an aluminum-plastic plate includes a pinch roller group 3, a pre-separation roller group 5, a separation pinch roller group 6, a surface aluminum winding device 7, a core layer winding device 8 and Bottom aluminum winding device 9;

[0030] The upstream of the pinch roller group 3 is provided with a side strip 2 unwinding device 1 or connected with the exit of the side strip 2 of the aluminum-plastic panel forming machine; the side strip 2 is the waste material cut from the aluminum-plastic panel forming machine, and the waste material is also Including the surface aluminum 21, the bottom aluminum 23 and the core layer 22, therefore, they cannot be recycled at the same time. The aluminum-plastic separation device can be connected with the forming machine, and can also coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com