a creasing machine

A creasing machine and creasing technology, used in container manufacturing machinery, paper/cardboard containers, packaging, etc., can solve problems such as easy sputtering and flow to other locations, cardboard rot, damage to cardboard quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] The embodiment is basically as follows:

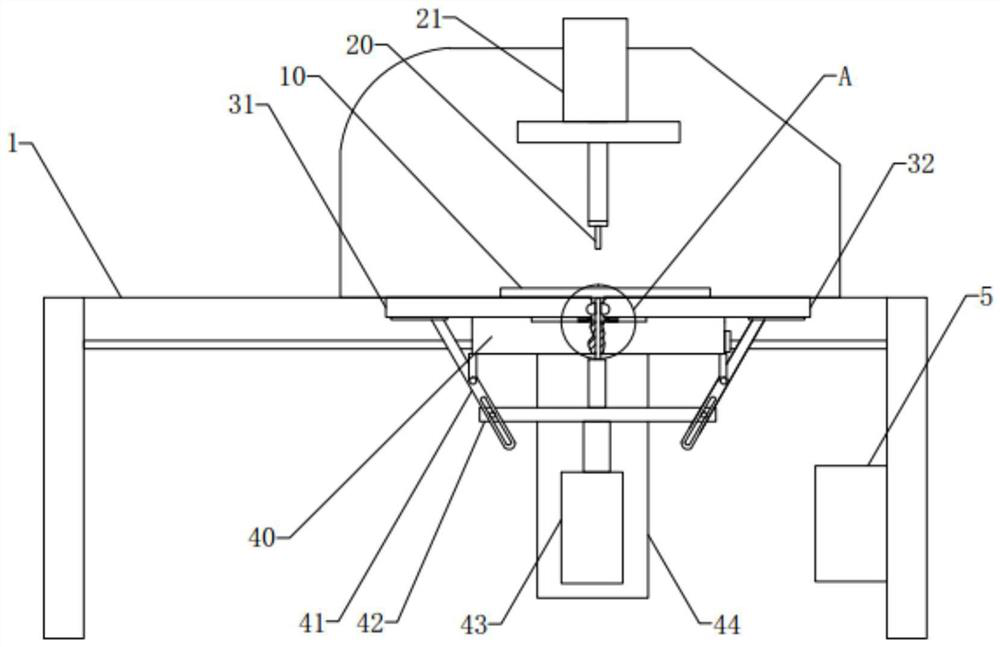

[0024] A creasing machine such as figure 1 As shown, it includes a frame 1 and an upper creasing knife 20 for creasing. A pressure cylinder 21 is fixed on the frame 1 , and the upper creasing knife 20 is fixed on the output shaft of the pressure cylinder 21 .

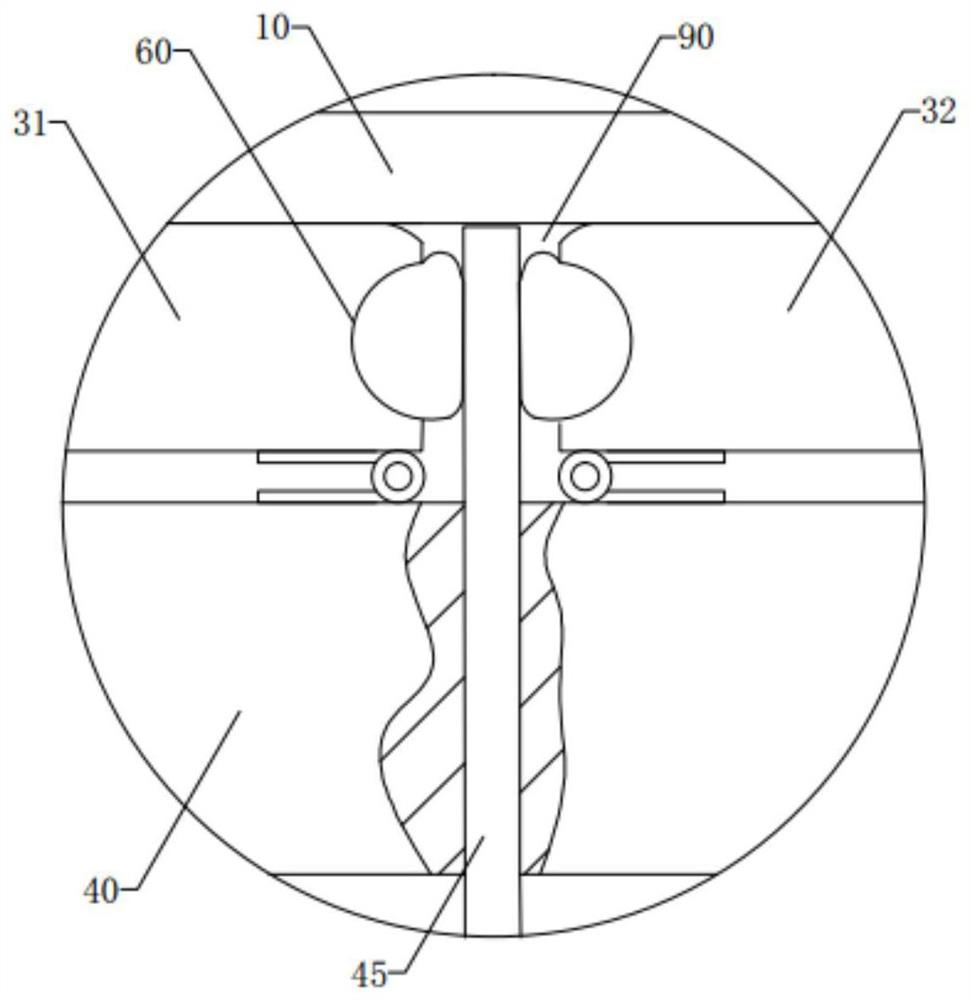

[0025] The frame 1 is slidably connected with a slide table 40 through a slide bar, and the slide table 40 can slide horizontally on the frame 1 . The upper surface of the slide table 40 is hinged with a first discharge plate 31 and a second discharge plate 32, and the hinges of the first discharge plate 31, the second discharge plate 32 and the slide table 40 are arranged oppositely, the first The upper surfaces of the discharge plate 31 and the second discharge plate 32 are flush. An indentation groove 90 is formed between the adjacent ends of the first discharge plate 31 and the second discharge plate 32 , and the indentation groove 90 is located directly below the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com