Prediction method of shot peening process parameters based on genetic algorithm optimized BP neural network

A BP neural network and shot peening technology, applied in biological neural network models, genetic laws, neural architectures, etc., can solve problems such as poor practicability, and achieve the effects of good practicability, improved prediction accuracy, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

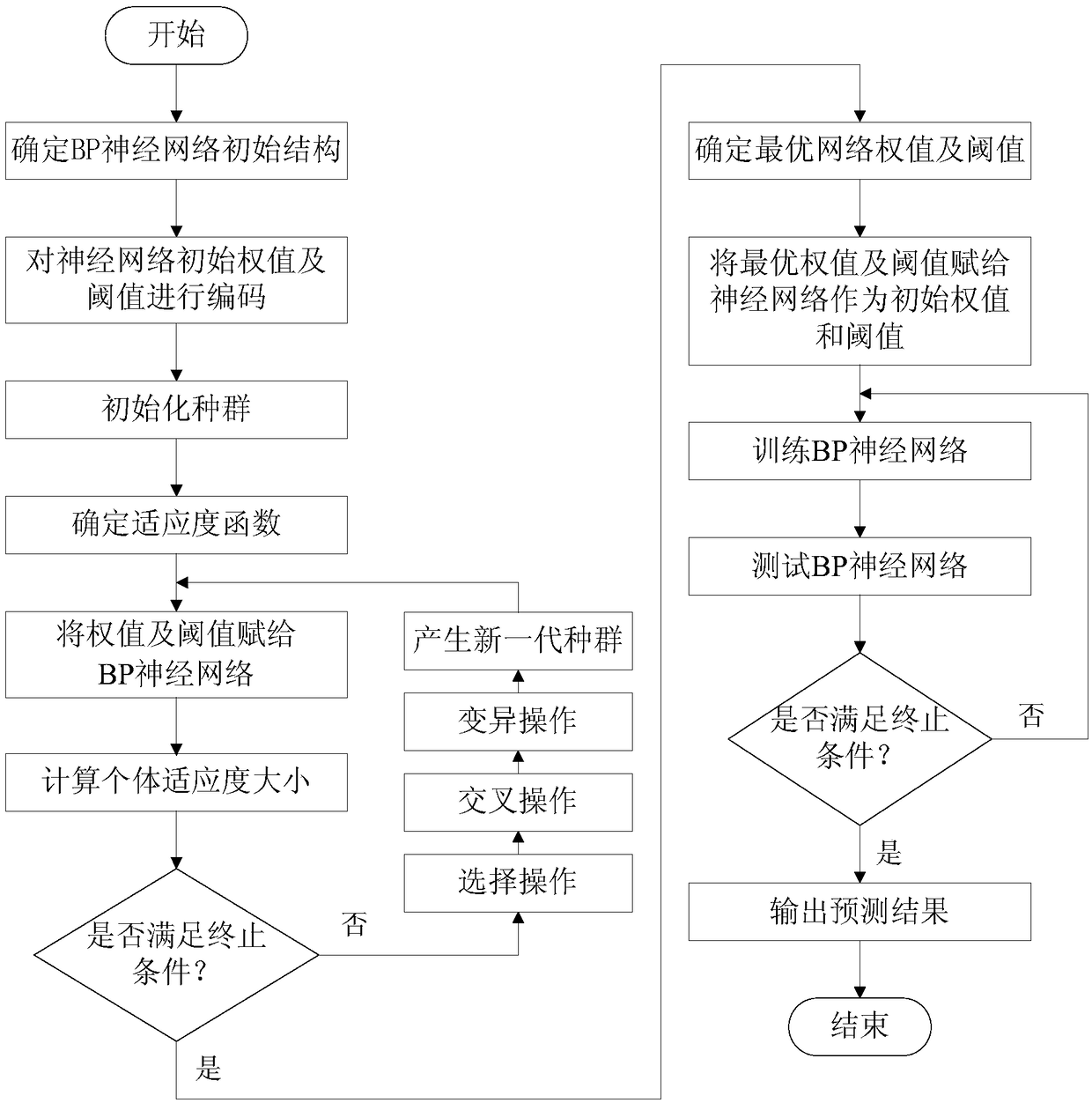

[0060] refer to Figure 1-6 . The present invention is based on the genetic algorithm optimization BP neural network shot peening process parameter prediction method concrete steps are as follows:

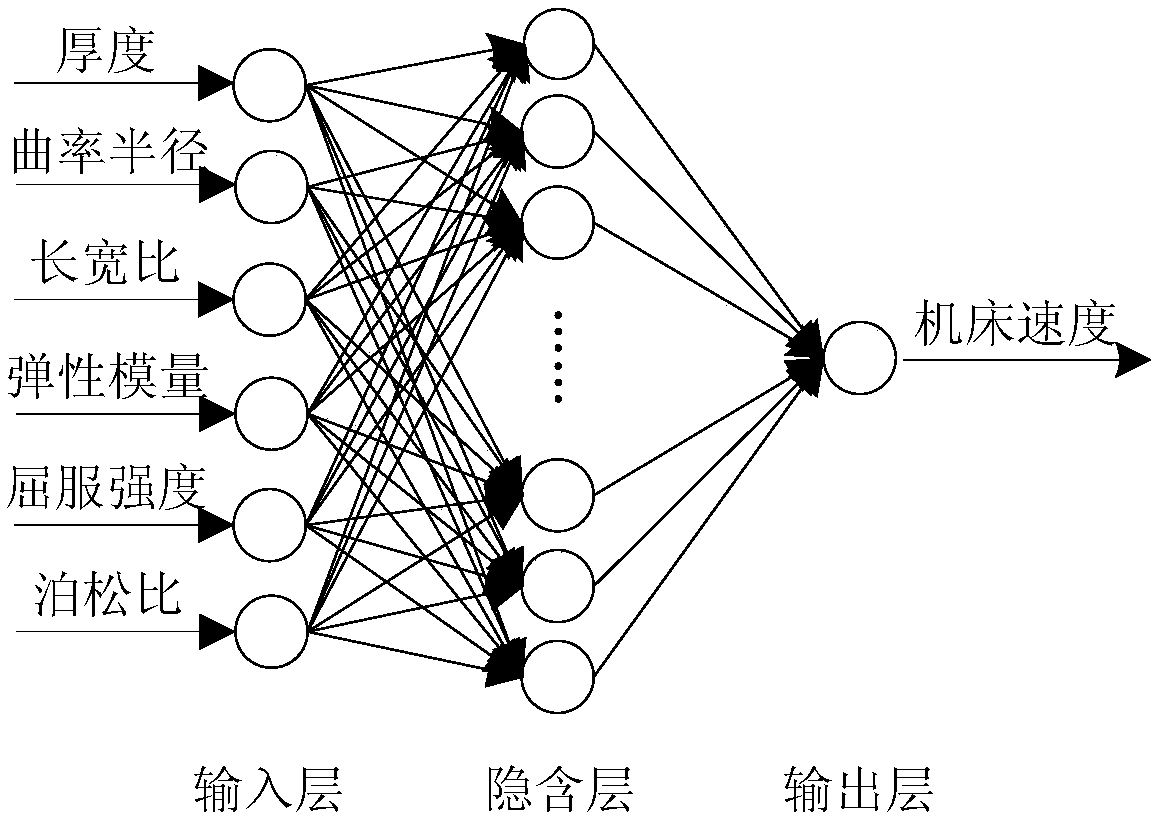

[0061] Step 1. Select the main factors that affect shot peening for testing, including the thickness of the part, the aspect ratio, the yield strength of the material, the elastic modulus, Poisson's ratio and the moving speed of the nozzle, so as to obtain the corresponding radius of curvature of the part.

[0062] The relationship between the radius of curvature of the part and the main factors affecting shot peening can be expressed as:

[0063] R=f(h,r,E,σ s ,ν,V)

[0064] In the formula, R is the radius of curvature, h is the thickness of the target part, r is the aspect ratio, E is the elastic modulus of the material, σ s is the yield strength, ν is Poisson's ratio, and V is the nozzle moving speed.

[0065] Determine the data sample set according to the test results, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com