A multi-channel heating device for organic nitrate based on cavity ring-down spectroscopy

A spectrum technology and a heating device technology, applied in the field of organic nitrate multi-channel heating devices, can solve the problems of complex structural parts, unsuitable for experiments, troublesome operation, etc., and achieve the effects of reasonable layout, easy portability and maintenance, and improved effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

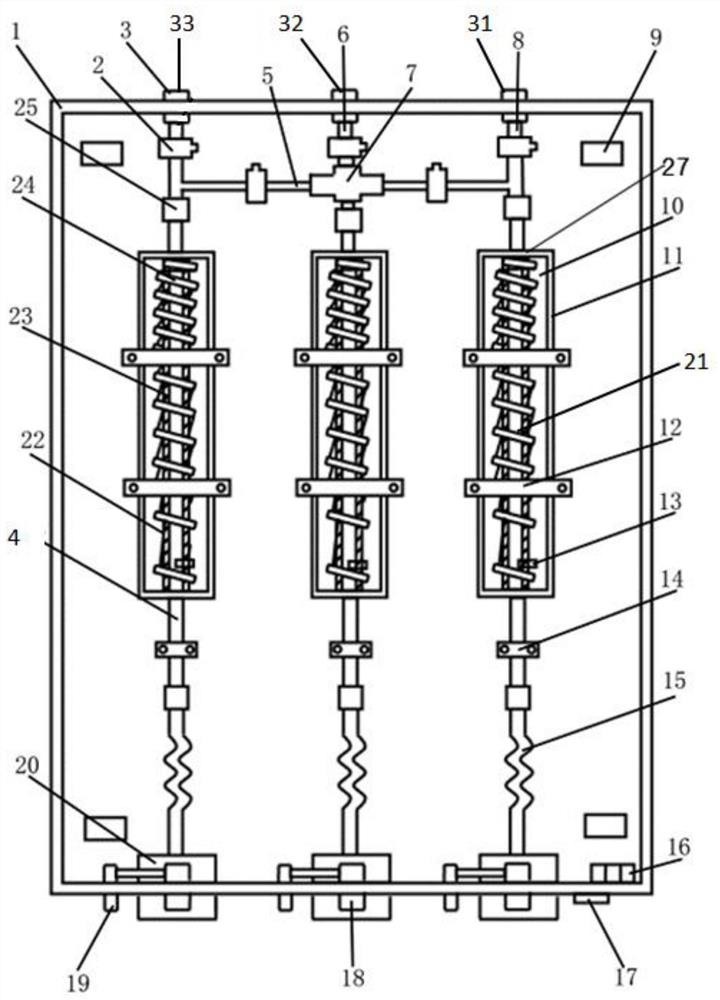

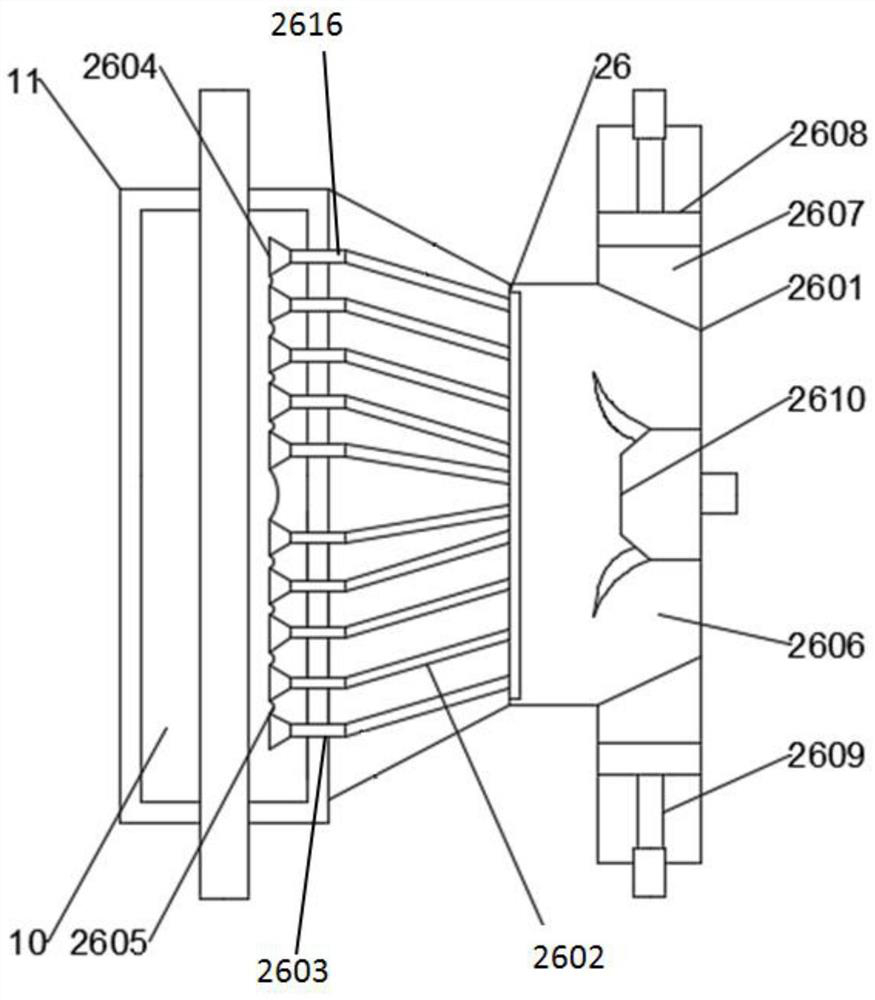

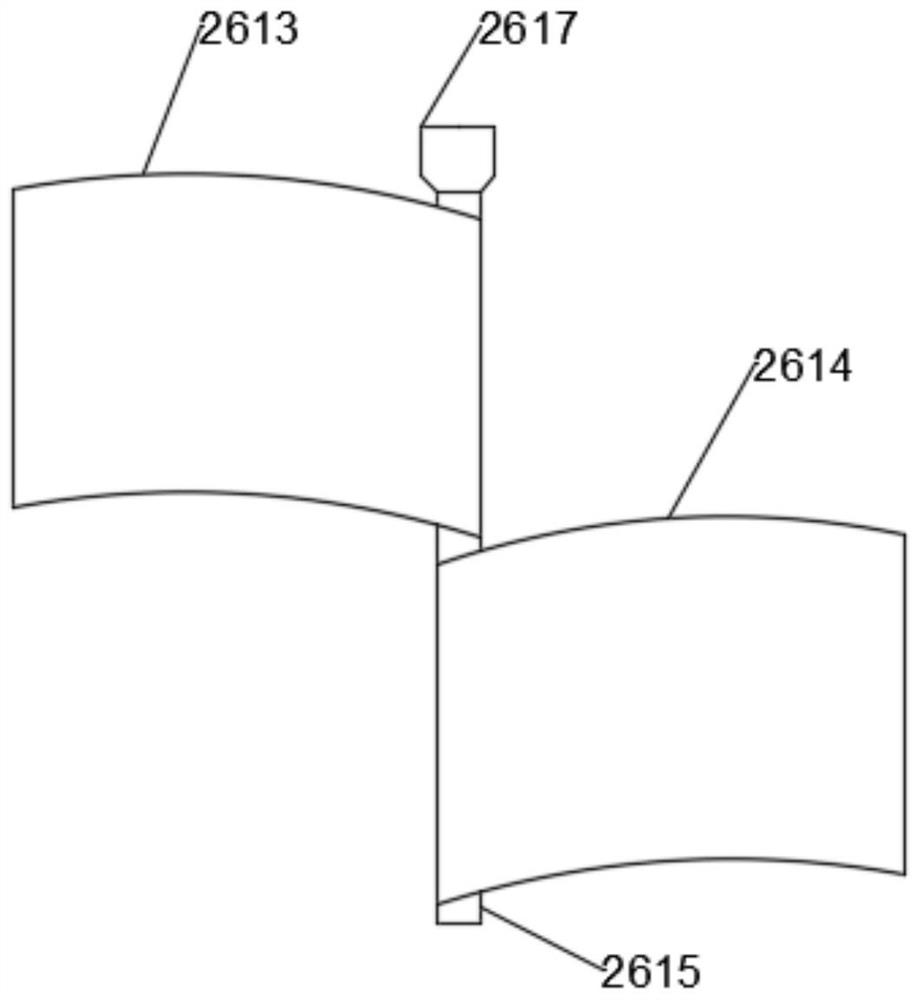

[0032] Such as Figure 1-4 As shown, a kind of organic nitrate multi-channel heating device based on cavity ring-down spectroscopy technology in this embodiment includes a housing 1, and a multi-channel heater 27 is arranged in the housing 1, and the channel heater 27 is used for the Organic nitrate gas is heated. One end of the multi-channel heater 27 is connected to several air inlets 3 , and the other end is connected to several air outlets 19 , wherein the air inlets 3 and the air outlets 19 are respectively located on opposite sides of the casing 1 . The multi-channel heater 27 is also connected with a heat equalization and flow guide mechanism 26 for dredging the internal airflow.

[0033] The organic nitrate gas to be detected enters the interior of the multi-channel heater 27 through the air inlet 3, and after being heated, it is discharged from the gas outlet 19 for detection, thereby realizing thermal decomposition of the organic nitrate gas. In addition, through m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com