Totally closed monitoring device for precision change of weighing lysimeter and evapotranspiration determining system

A monitoring device and lysimeter technology, applied in measuring devices, material weighing, instruments, etc., can solve the problems of complex structure design, poor timeliness, offset of box components, etc., and achieve simple changes in weighing accuracy , to achieve the effect of changing weighing accuracy, quick installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

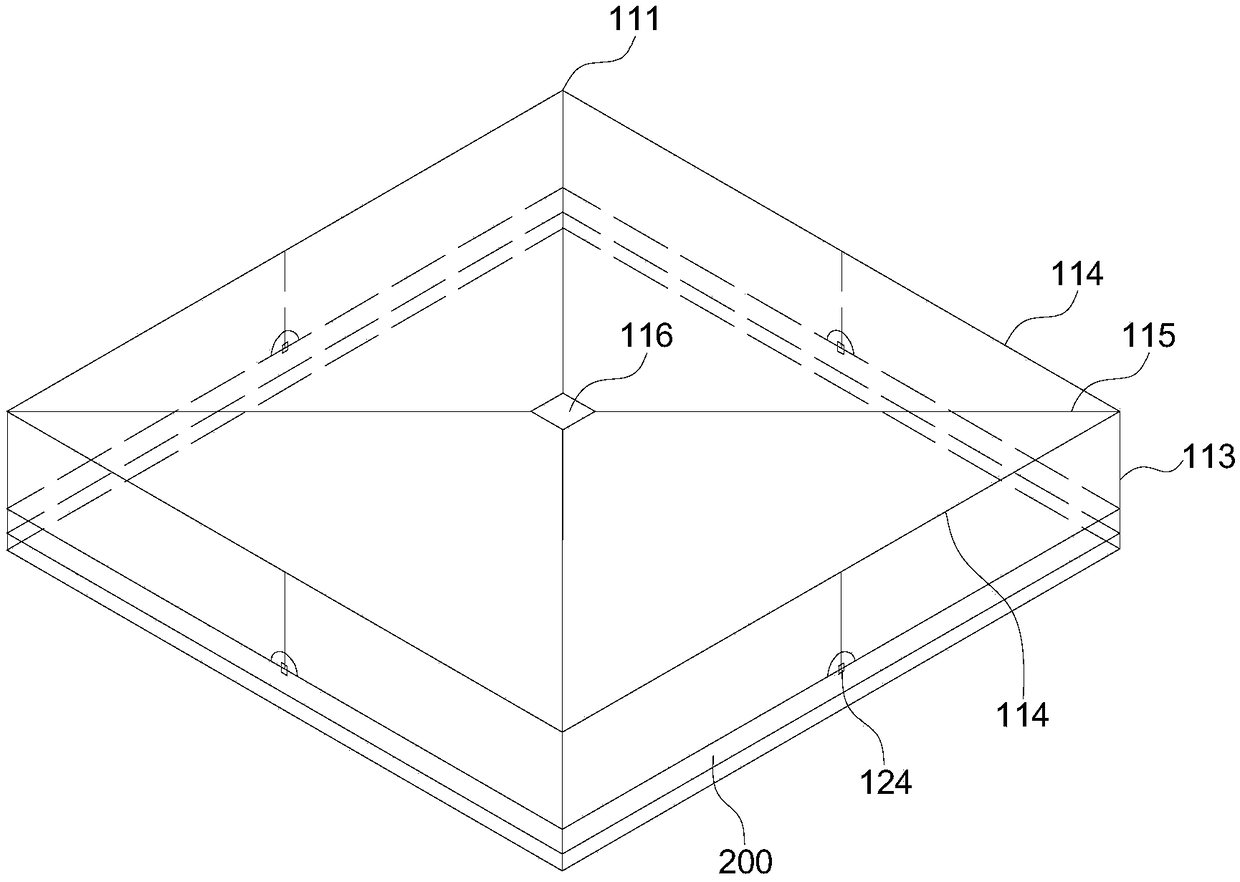

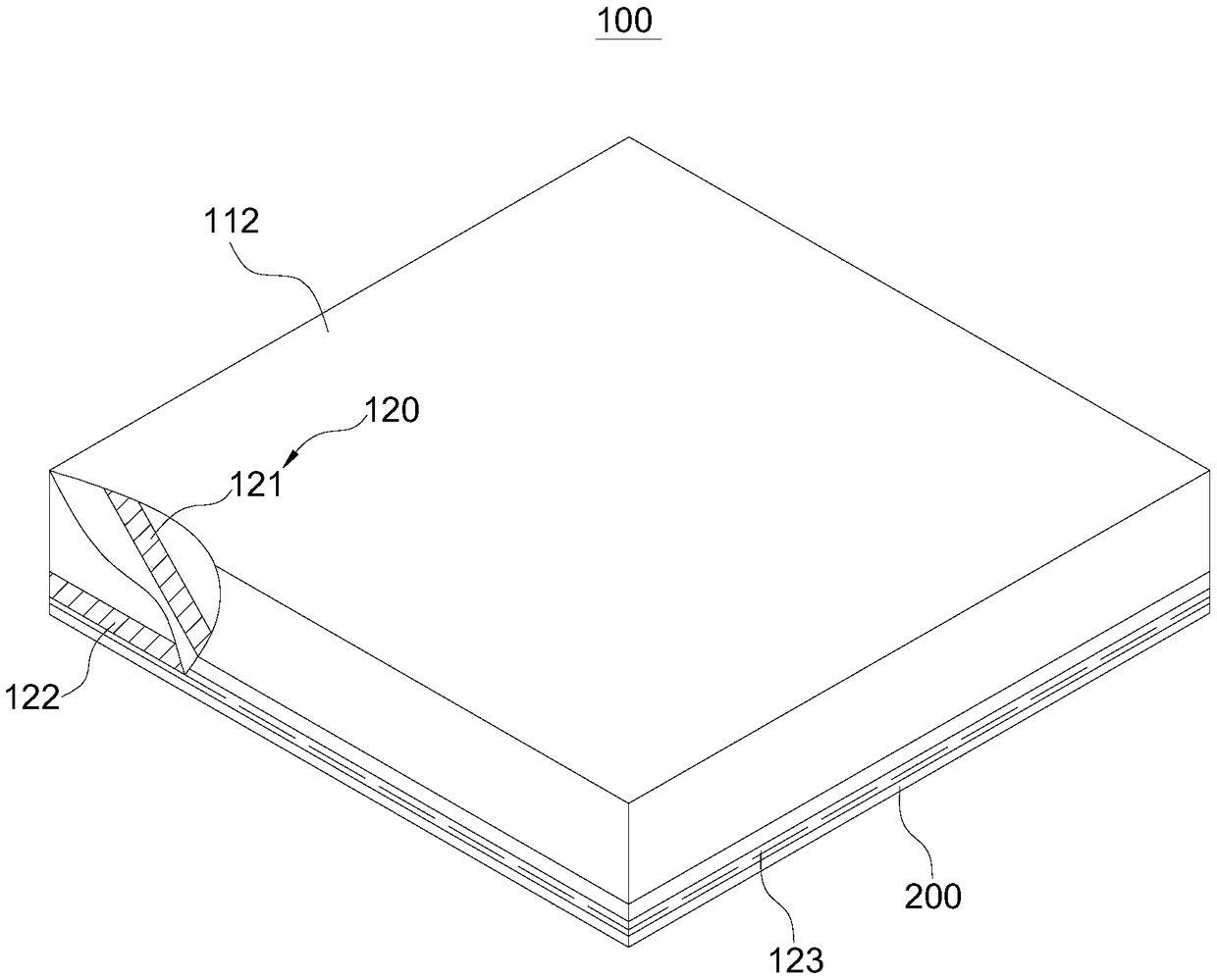

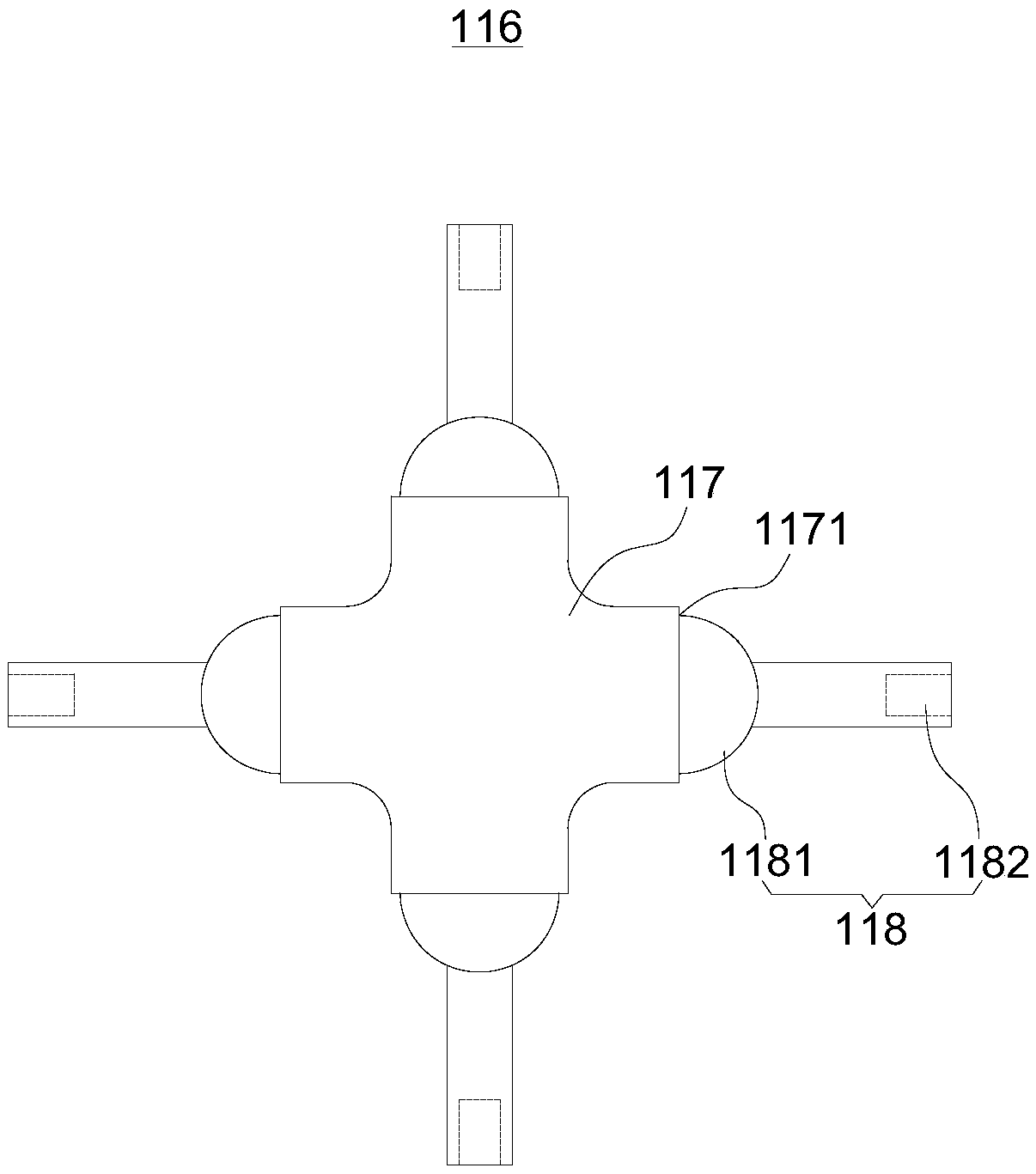

[0033] Please refer to figure 1 with figure 2 , the present embodiment provides a fully enclosed monitoring device 100 for the accuracy change of the weighing lysimeter, which is used to monitor the accuracy change of the weighing lysimeter 200 . The specific results include a sealed box 110 and a connecting piece 120. The sealed box 110 is used to be sleeved on the outside of the weighing lysimeter 200 so that the weighing lysimeter 200 is in a closed state. The connecting piece 120 can be connected to the sealed Box 110 and weighing lysimeter 200 .

[0034] In this embodiment, the weighing-type lysimeter 200 is set in a sealed box 110 so that the weighing-type lysimeter 200 is in a relatively closed state. At this time, accuracy monitoring can avoid the influence of water vapor exchange. At the same time, it can reduce the influence of external air flow, temperature, weather, etc., and ensure the accuracy of monitoring results.

[0035]The sealed box 110 is mainly used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com