Optical fiber temperature and vibration series integrated sensor based on blazed grating and optical fiber grating

A technology of blazed gratings and fiber gratings, applied in the direction of thermometers, instruments, thermometers, etc. that change physically/chemically, can solve the problems of difficult structure assembly, troublesome maintenance, zero point offset, etc., and achieve strong anti-electromagnetic interference ability and reliable connection The effect of high stability and small zero drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0044] Combine below Figure 1 to Figure 9 The technical solution provided by the present invention is described in more detail.

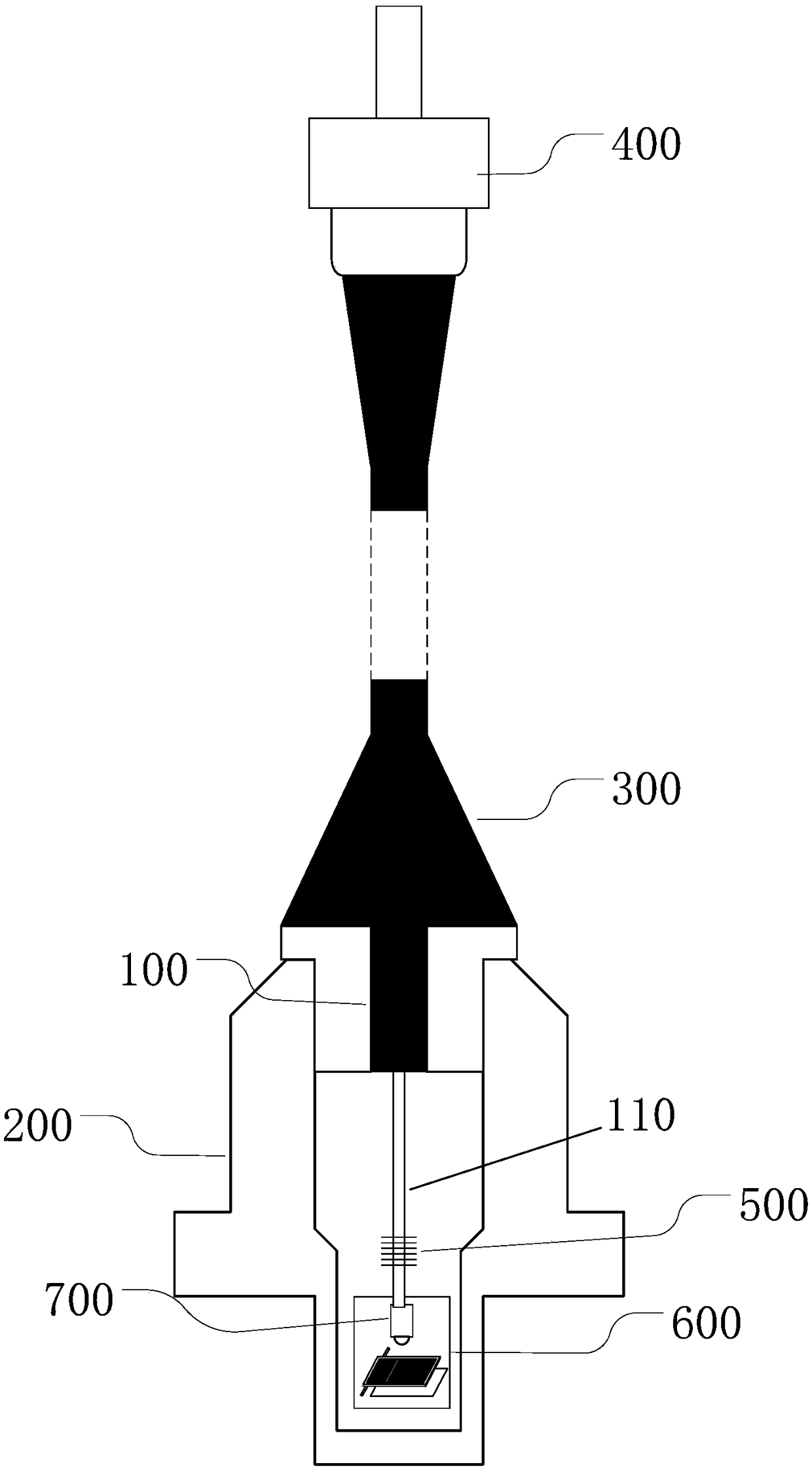

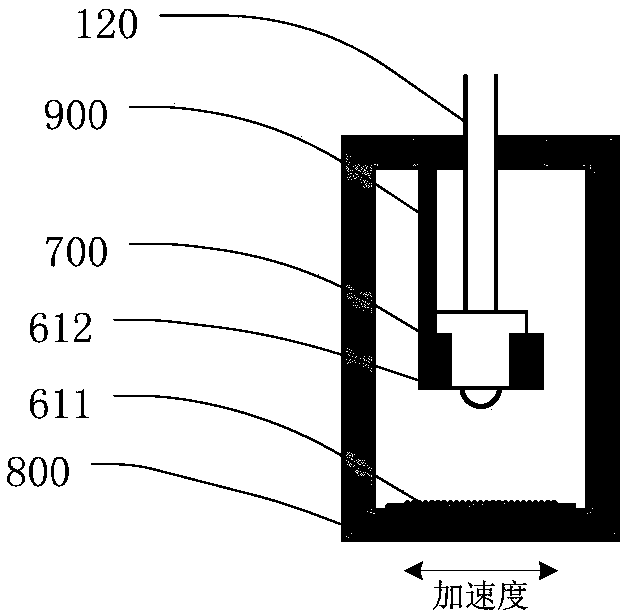

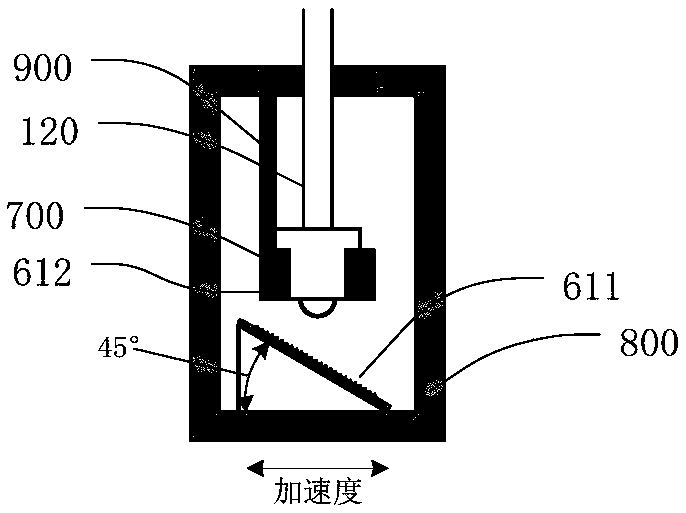

[0045] like Figure 1 to Figure 9 As shown, this optical fiber temperature vibration series integrated sensor based on blazed grating and fiber grating includes:

[0046] A housing, the fiber grating and the blazed grating vibration measurement structure are arranged inside;

[0047] An optical cable, one end of which extends into the housing and leads out a path of optical fiber, respectively the path of optical fiber and the path of optical fiber, the fiber grating is engraved on the path of optical fiber, and the blazed grating vibration measurement structure is connected to the path of op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com