Dual reinforcing ring of marine large liquefied gas storage tank and construction scheme of dual reinforcing ring

A technology for liquefied gas storage tanks and reinforcement rings, which is applied in metal processing equipment, fixed-capacity gas storage tanks, gas/liquid distribution and storage, etc., and can solve the problems of not being able to meet the structural strength requirements of large liquid tanks and increasing volume. Relieve the pressure of site layout and hoisting and transportation, improve manufacturing efficiency and facilitate use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

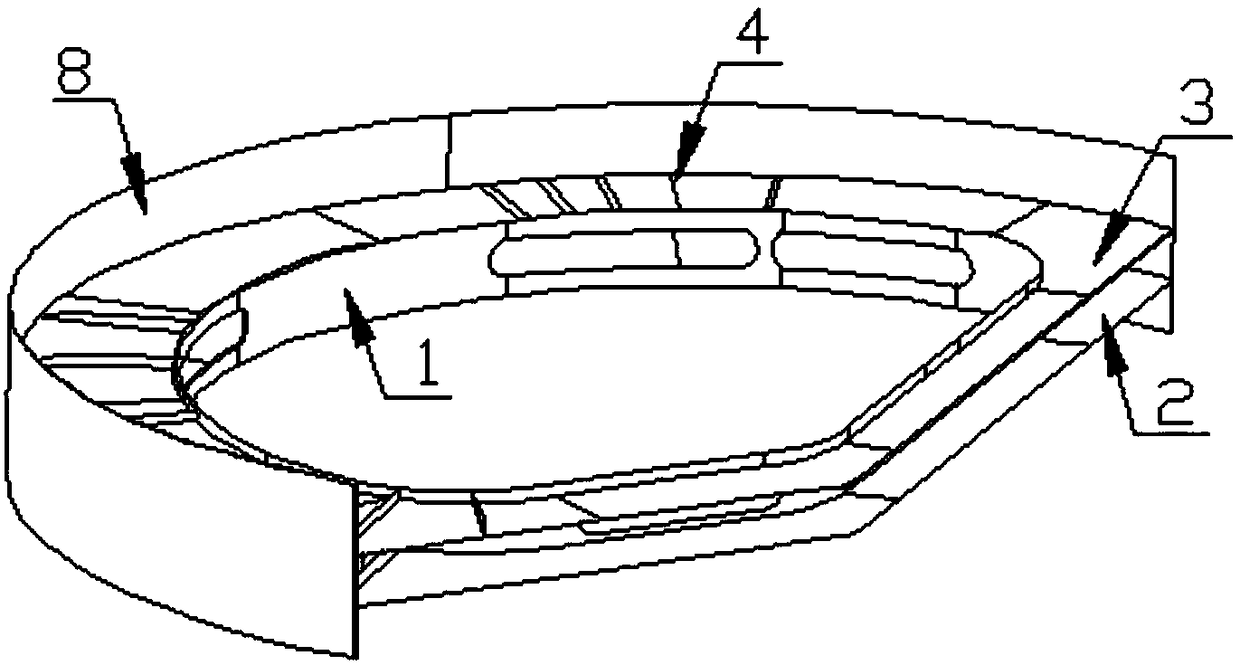

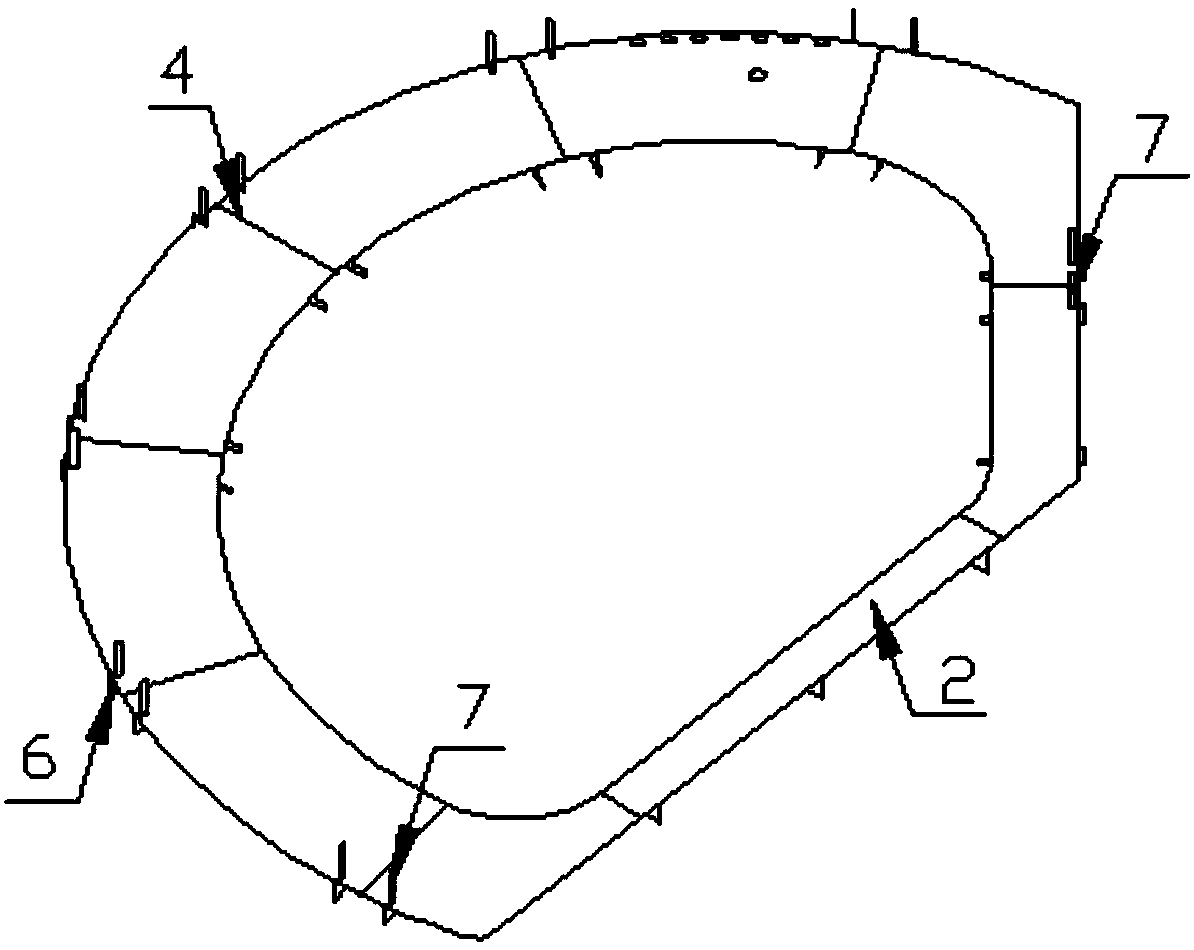

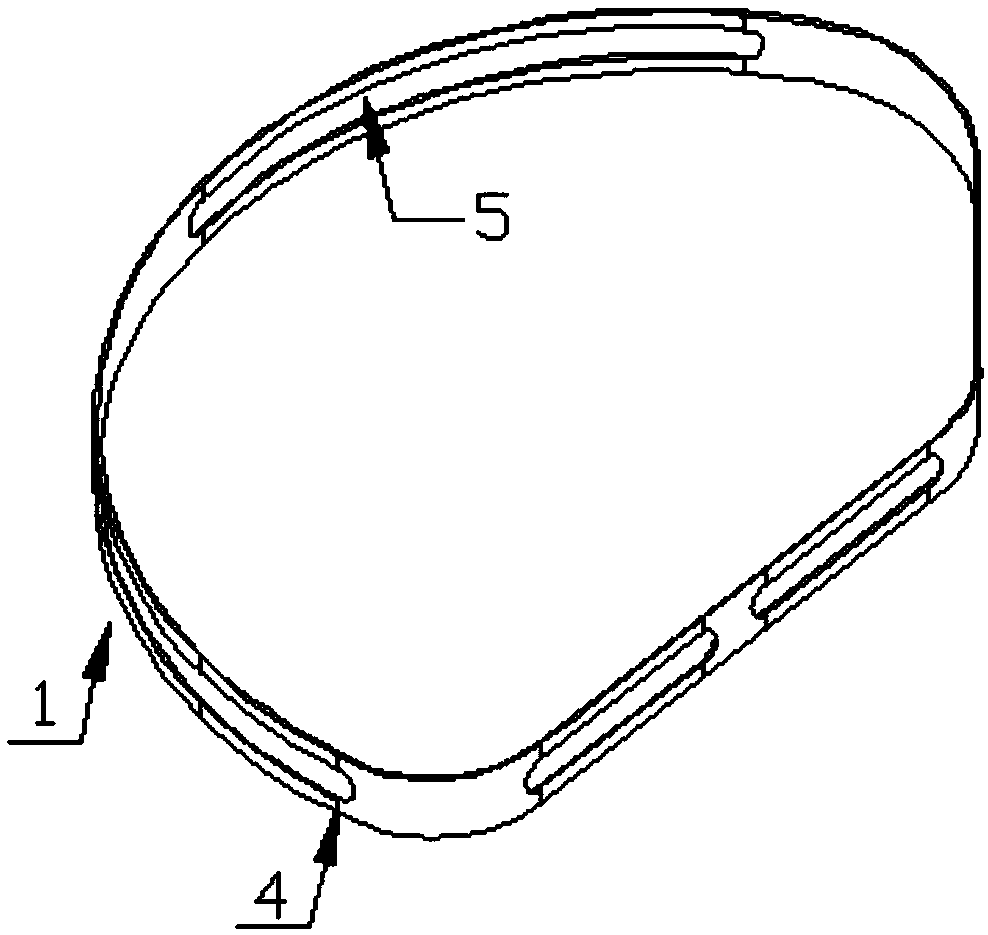

[0031] Such as Figure 1-7 As shown, this specific embodiment adopts the following technical solutions: a double-channel reinforcement ring for a large-scale liquefied gas storage tank for ships, including a panel 1, a web and a rib 4, the panel 1 is provided with a web, and the web is provided with Two layers, the web includes the bow web 2 and the stern web 3, the bow web 2, the stern web 3 and the panel 1 form a reinforced ring structure, and the bow web 2 and the stern web 3 are provided with The mounting holes corresponding to the outline of the panel 1, the bow web 2, the stern web 3 and the panel 1 are provided with stiffeners 4, and the panel 1 between the bow web 2 and the stern web 3 is provided with A plurality of round holes 5, the outer bottom of the bow web 2 is provided with a mounting frame 6, the top of the outer edge of the bow web 2 is provided with a cam 7, and the mounting frame 6 is set correspondingly to the cam 7 A casing 8 is installed on the outer ed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com