Soft rock roadway bottom board anchoring, grouting and reinforcing method

A technology of floor and roadway, which is used in earth-moving drilling, installation of bolts, mining equipment, etc., can solve the problems of difficult to achieve long-term stability requirements of coal and rock mass on the floor of deep soft rock roadway, small support range and low strength, etc. Achieve the effect of improving the stress state of the floor and the self-supporting capacity of the surrounding rock, a large support range, and a high surface protection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

[0037] An anchoring and grouting reinforcement method for a soft rock roadway floor, comprising the following steps:

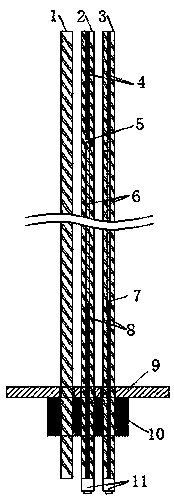

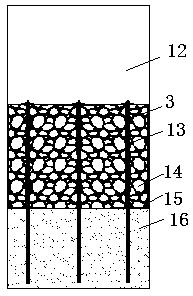

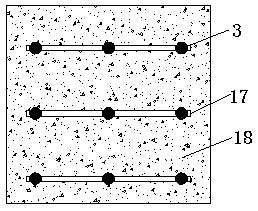

[0038] (1) Opening of grouting holes: On the surface of the bottom plate of the roadway 12, bottom plate drillings 13 that penetrate deep into the stable rock formation 16 of the bottom plate are opened, and at least two adjacent grouting holes 13 in the same row of bottom plate drilling holes 13 are used as the bottom plate of the roadway 12 The grouting unit; as an embodiment of the present invention, the grouting unit includes three grouting channels 13 . Among them, the drilling holes can be drilled with large-aperture floor drilling with existing common drilling rigs in coal mines, which not only meets the needs of the reinforcement range of the broken area of the floor, but also facilitates the inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com