Method for regenerating rolled and used lubricating oil

A technology for waste lubricating oil and solution, applied in the direction of lubricating composition and the like, can solve the problems of slow development of regeneration process, pollute the environment, waste resources, etc., and achieve the effects of good application prospect, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of regeneration method of rolling waste lubricating oil, specifically comprises the following steps:

[0026] (1) Heating the rolling waste lubricating oil to 60°C and standing for 4 days for pretreatment;

[0027] (2) Take 50ml of rolling waste lubricating oil and heat it to 60°C, add 6ml of ferric chloride solution with a concentration of 0.2mol / L to it, and then add 15ml of sodium hydroxide solution with a concentration of 1.0mol / L. Stir continuously for 5 min at a speed of 1 min;

[0028] (3) Screen the fly ash with 100 and 250 mesh screens respectively, then add 2.0g fly ash to the mixture in step (2), continue stirring for 20min at 500r / min, and finally mix the mixture at 1000r / min After centrifugation for 10 min, the obtained supernatant is the regenerated base oil.

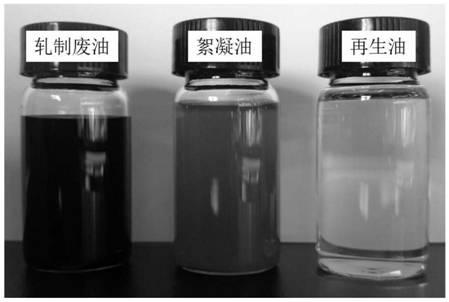

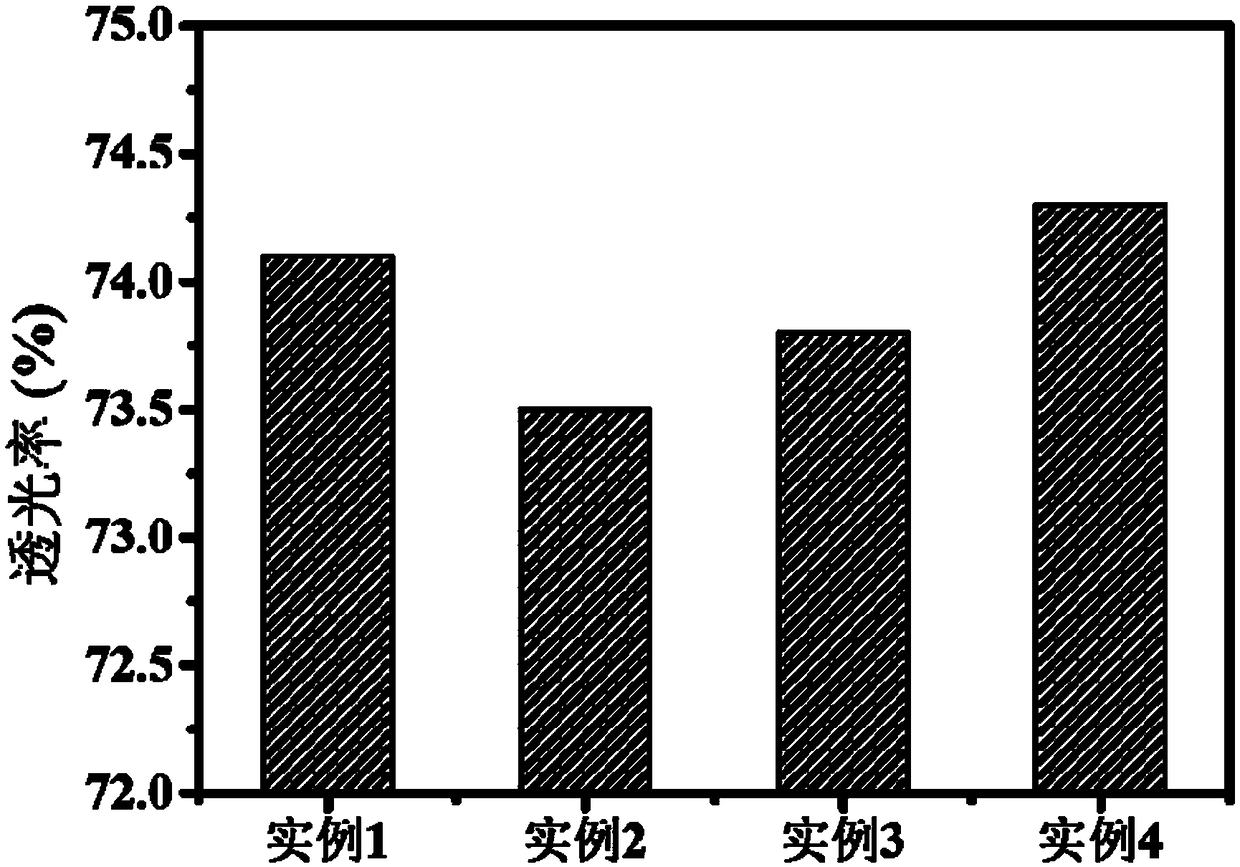

[0029] In this example, rolling waste lubricating oil, flocculated oil and recycled oil such as figure 1 As shown, the UV absorbance of regenerated oil is as figure 2 Shown, the recovery...

Embodiment 2

[0031] A kind of regeneration method of rolling waste lubricating oil, specifically comprises the following steps:

[0032] (1) Heating the rolling waste lubricating oil to 30°C and standing for 2 days for pretreatment;

[0033] (2) Take 80ml of rolling waste lubricating oil and heat it to 30°C, add 4ml of ferric chloride solution with an equal concentration of 0.1mol / L to it, and then add 10ml of sodium hydroxide solution with a concentration of 0.8mol / L. Stir continuously for 2min at a speed of 1 / min;

[0034] (3) Screen the fly ash with 100 and 300 mesh screens respectively, then add 1.0g of fly ash to the mixture in step (2), continue to stir for 5min at 300r / min, and finally mix the mixture at 1500r / min After centrifugation for 10 min, the obtained supernatant is the regenerated base oil.

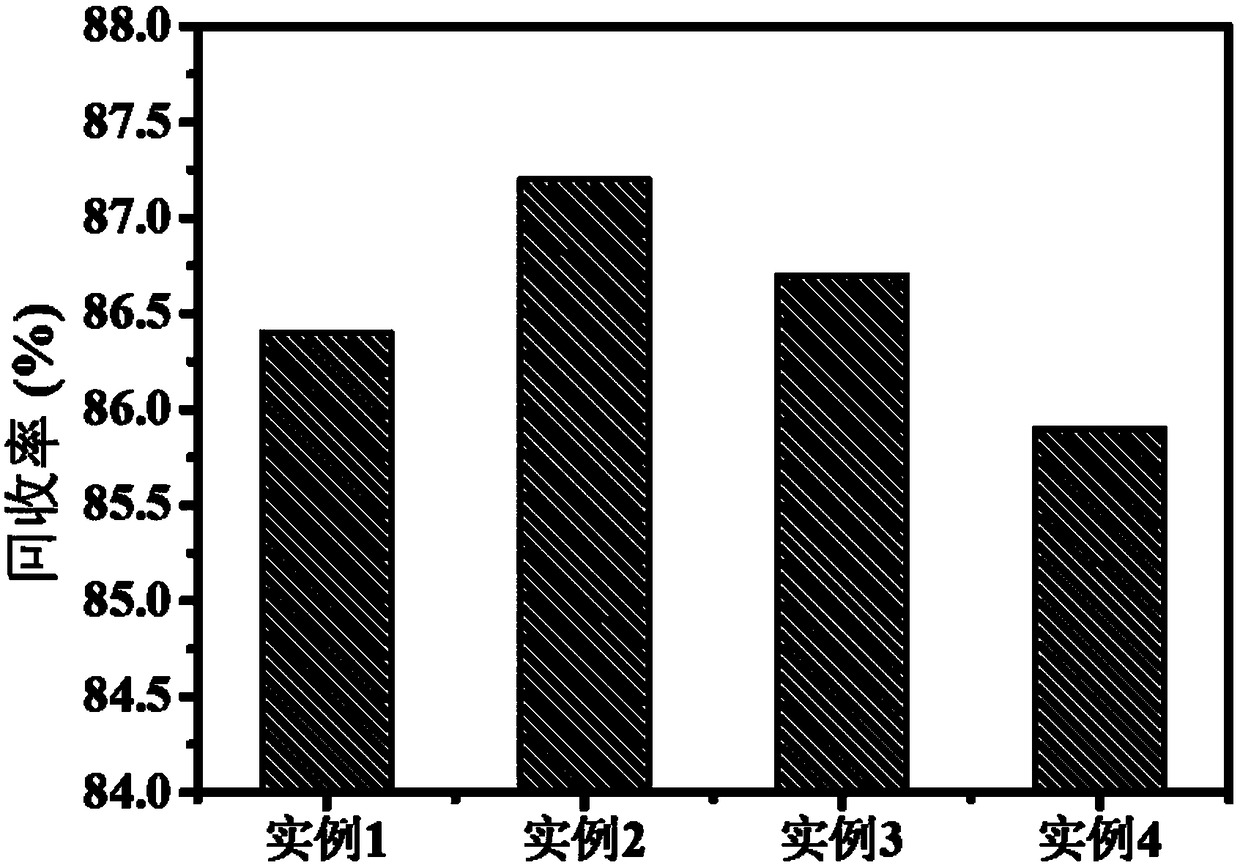

[0035] In this example, the UV absorbance of the regenerated oil was as figure 2 As shown, the recovery rate of recycled oil is as image 3 The physical and chemical properties of...

Embodiment 3

[0041] A kind of regeneration method of rolling waste lubricating oil, specifically comprises the following steps:

[0042] (1) Heating the rolling waste lubricating oil to 40°C and standing for 4 days for pretreatment;

[0043] (2) Take 80ml of rolling waste lubricating oil and heat it to 80°C, add 10ml of ferric chloride solution with an equal concentration of 0.2mol / L to it, and then add 20ml of sodium hydroxide solution with a concentration of 1.5mol / L. Stir continuously for 10min at a speed of 1 / min;

[0044] (3) Screen the fly ash with 50 and 200 mesh screens respectively, then add 3.0g fly ash to the mixture in step (2), continue stirring for 30min at 400r / min, and finally mix the mixture at 800r / min Centrifuge for 8 minutes, and the supernatant obtained is the regenerated base oil.

[0045] In this example, the UV absorbance of the regenerated oil was as figure 2 As shown, the recovery rate of recycled oil is as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com