Coupling device and process for deeply treating landfill leachate

A technology for landfill leachate and advanced treatment, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The process is simple and the effect of improving the current utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

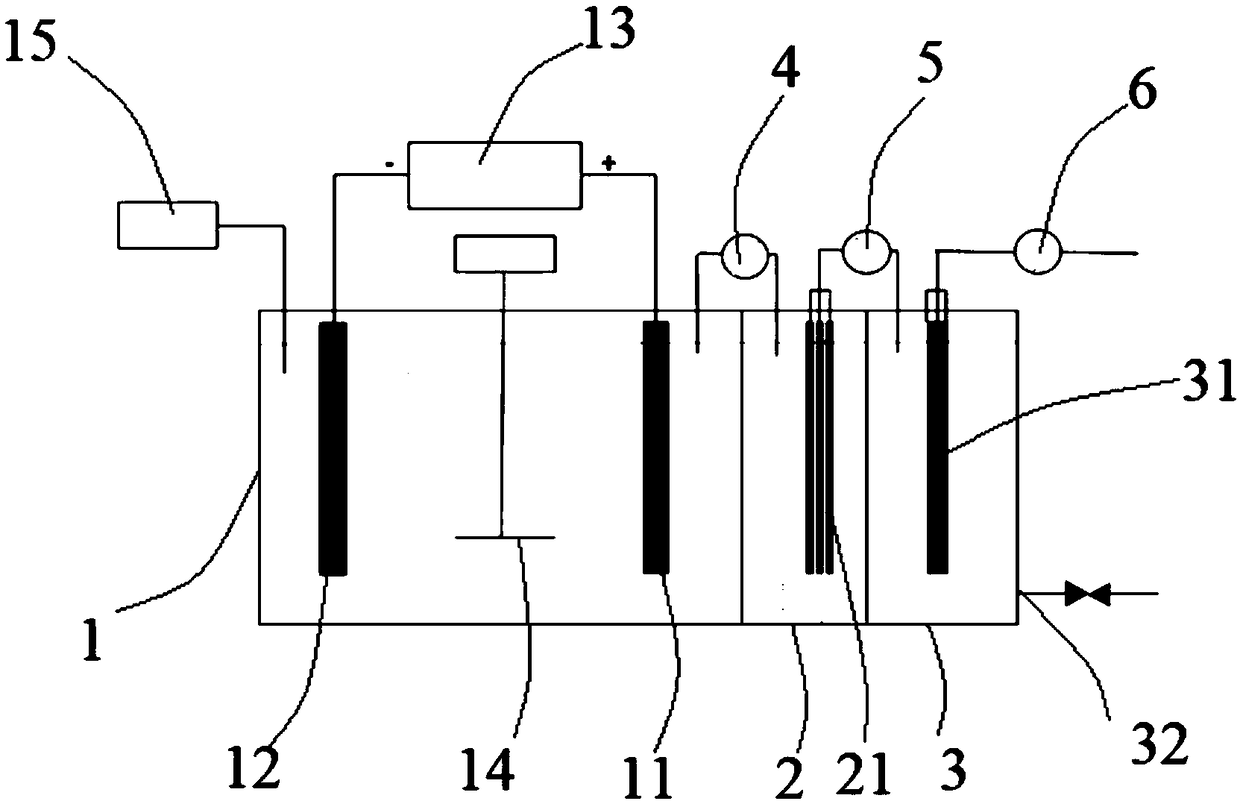

[0037] combine figure 1 As shown, a coupling device for advanced treatment of landfill leachate, including:

[0038] The electrocoagulation device 1 is used to perform electrocoagulation of pollutants on the landfill leachate that has not been discharged up to the standard after biochemical treatment;

[0039] The first-stage microfiltration ceramic membrane 21 device 2 performs primary filtration on the landfill leachate after electrocoagulation of pollutants;

[0040] The secondary ultrafiltration ceramic membrane 31 device 3 performs secondary filtration on the landfill leachate after primary filtration;

[0041] The electrocoagulation device 1 is connected to the first-stage microfiltration ceramic membrane device 2 through the first water pump 4; the first-stage microfiltration ceramic membrane device 2 is connected to the second-stage ultrafiltration ceramic membrane device 3 through the second water pump 5;

[0042] The membrane pore diameter of the ultrafiltration ce...

Embodiment 2

[0050] The coupling process for advanced treatment of landfill leachate using the above-mentioned advanced treatment coupling device for landfill leachate includes the following steps:

[0051] 1) Put the landfill leachate that has not been discharged up to the standard after biochemical treatment into the electrocoagulation device 1, and electrocoagulate the pollutants in the landfill leachate to obtain the first-grade landfill leachate;

[0052] 2) Put the first-level landfill leachate into the first-level microfiltration ceramic membrane device 2, perform one-time filtration, and obtain the second-level landfill leachate;

[0053] 3) Put the secondary landfill leachate into the secondary ultrafiltration ceramic membrane device 3 for secondary filtration to obtain the landfill leachate discharged up to the standard.

[0054] Because the effluent of landfill leachate has high salt content and high solid concentration after biochemical treatment, the advanced treatment couplin...

Embodiment 3

[0057] The coupling process for advanced treatment of landfill leachate using the above-mentioned advanced treatment coupling device for landfill leachate includes the following steps:

[0058] 1) The landfill leachate that has not been discharged up to the standard after biochemical treatment is put into the electroflocculation device 1, and the pollutants in the landfill leachate are electrocoagulated to obtain a first-grade landfill leachate, wherein the soluble anode plate 11 of the electroflocculation device 1 is a cast iron anode plate, the cathode plate 12 is a stainless steel cathode plate, and the electric flocculation current density is 50mA / cm 2 , the electrocoagulation pH value is 8, the electrocoagulation time is 70min, and the net distance between the soluble anode plate 11 and the cathode plate 12 is 5cm;

[0059] 2) Put the first-level landfill leachate into the first-level microfiltration ceramic membrane device 2, and perform one-time filtration to obtain the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com