Canned bottle production line with automatic data collecting function and control method thereof

An automatic collection and data collection module technology, applied in bottle filling, liquid bottling, packaging, etc., can solve the problems of increased production costs, reduced brand reputation, heavy economic burden, etc., to simplify transformation and realize abnormal data. Effects of handling and stability assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

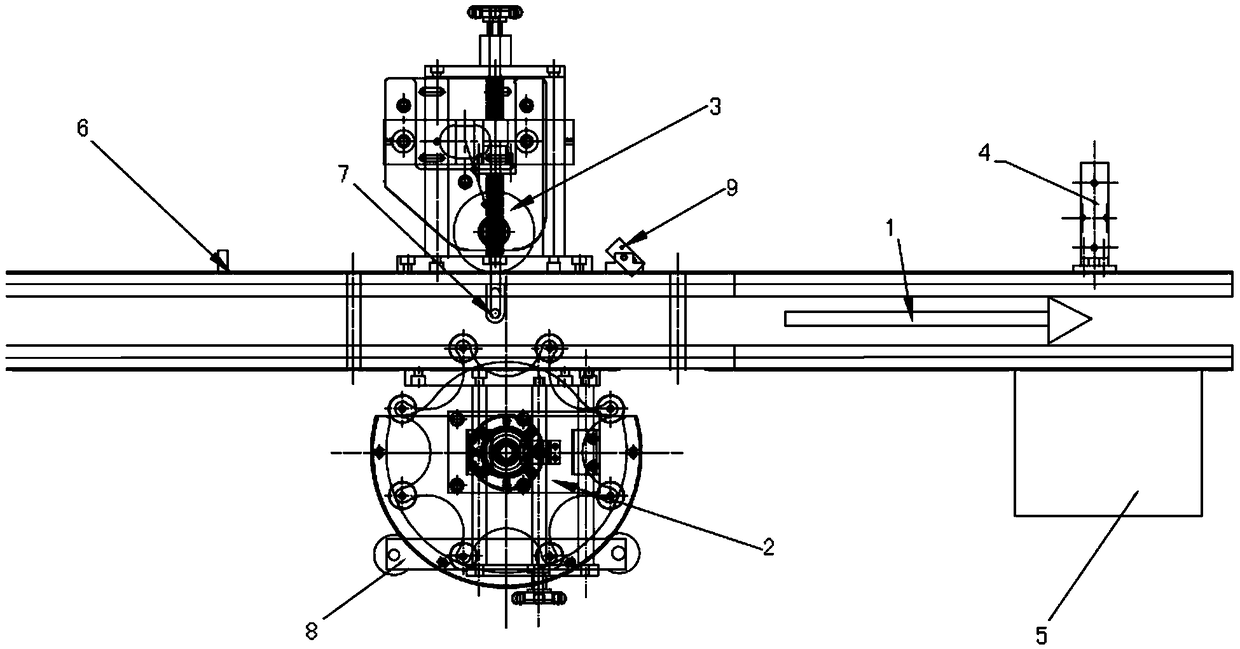

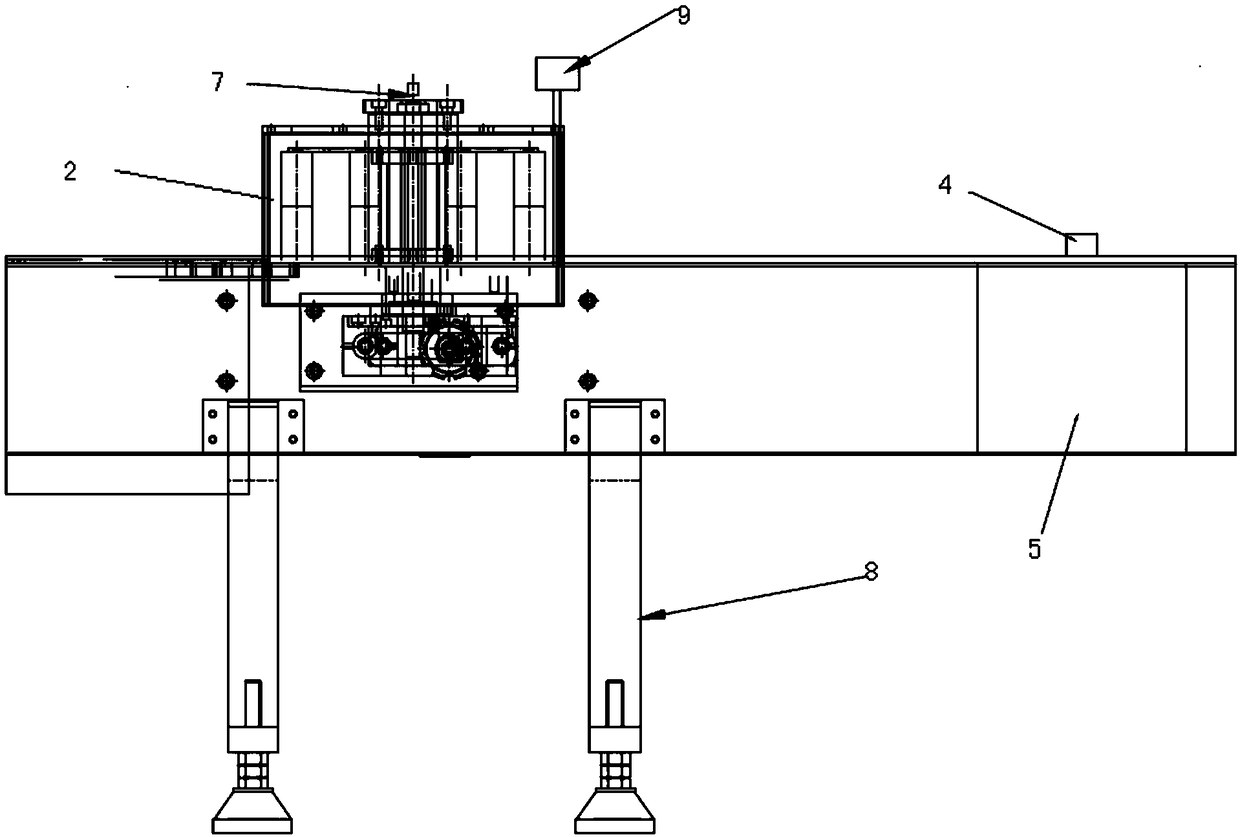

[0037] figure 1 It is a top view of the canned bottle production line with automatic data collection function in the embodiment of the present invention; figure 2 It is the front view of the production line for canned bottles with automatic data collection function in the embodiment of the present invention.

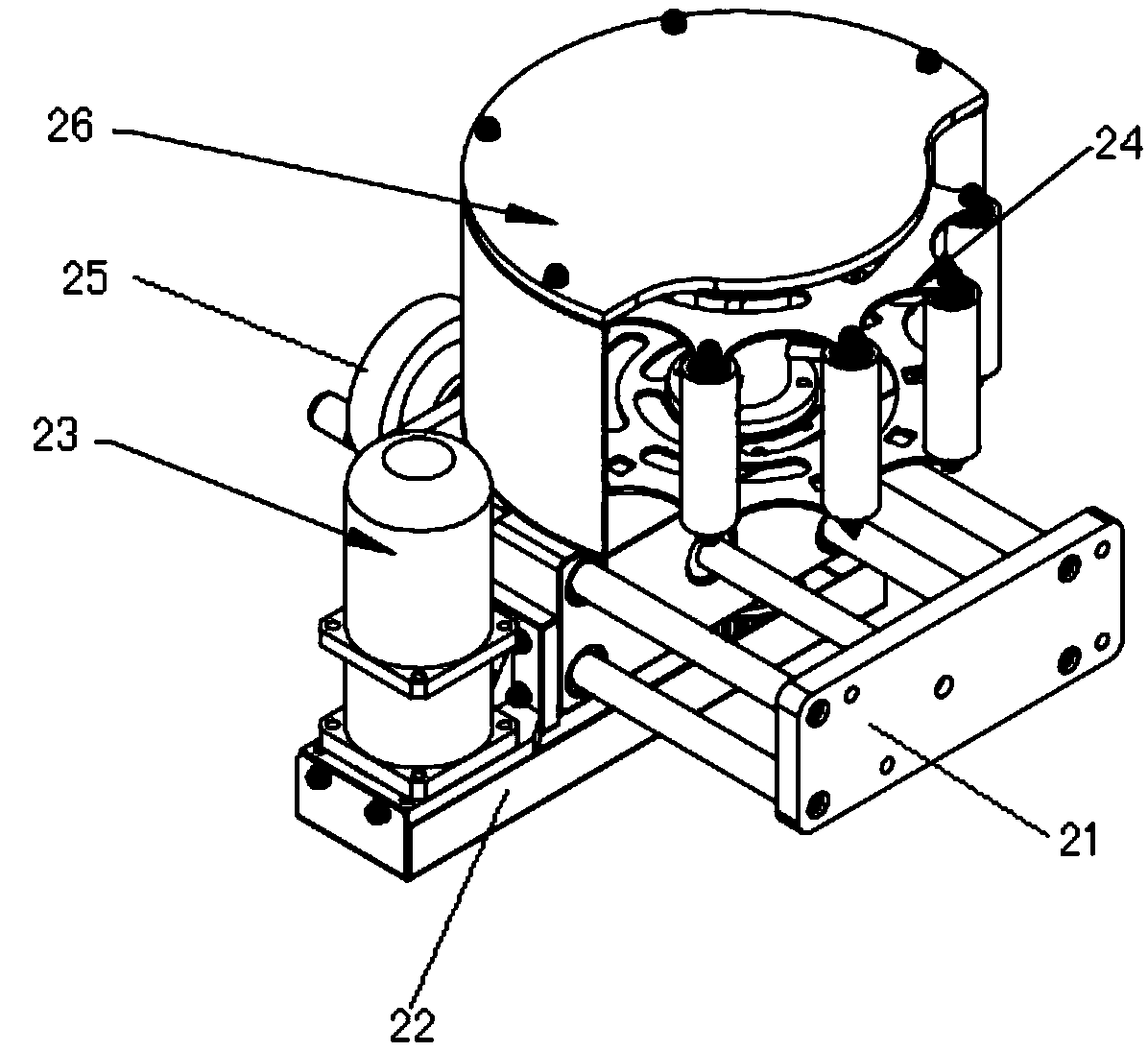

[0038] See figure 1 and figure 2 , the canned bottle production line with the automatic data collection function provided by the present invention comprises a conveyor belt, a star wheel mechanism 2, a runner mechanism 3, a rejecting mechanism, a data acquisition module and a control module, and the star wheel mechanism 2 and the runner mechanism 3 The additional tripod 8 is arranged symmetrically and at the same height on both sides of the conveyor belt. The rejecting mechanism includes a rejecting cylinder 4 and a rejecting hopper 5. The re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com