Colored steel plate rock wool feeding machine

A color steel plate and rock wool technology, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of inability to meet the needs of color steel plate production rhythm, time-consuming and laborious, and high operating intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

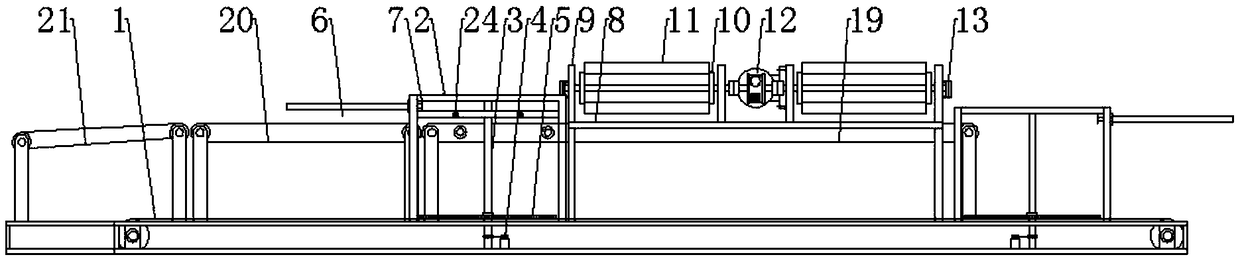

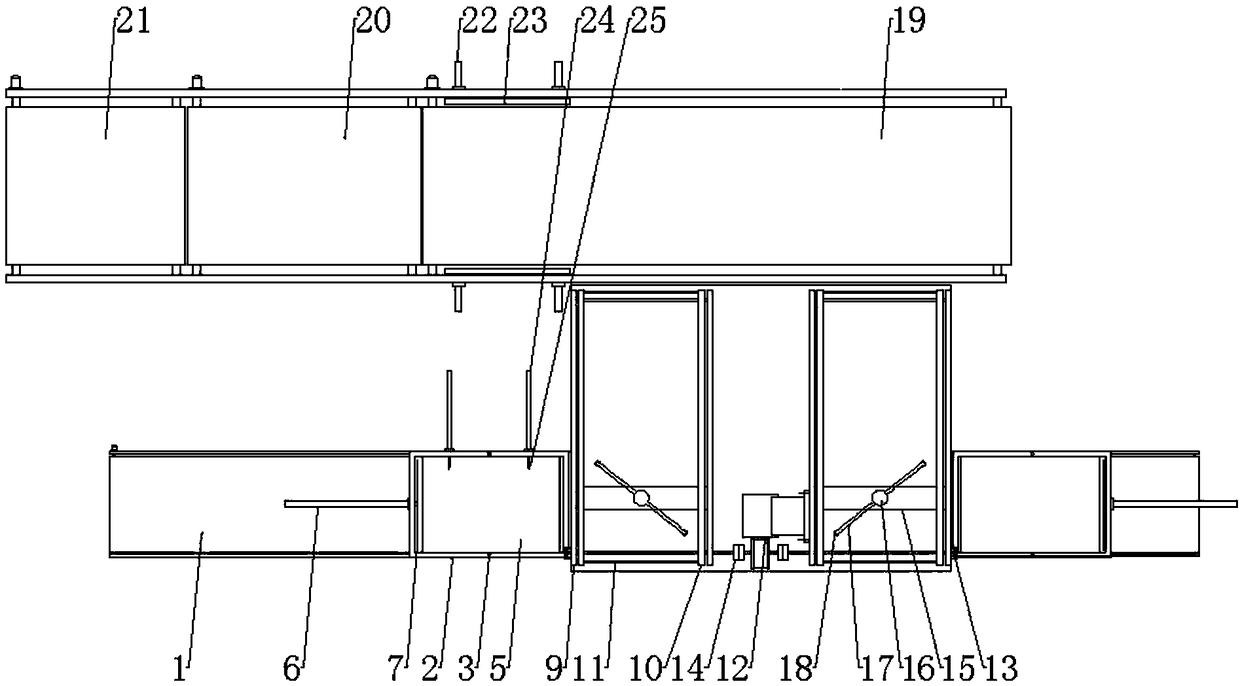

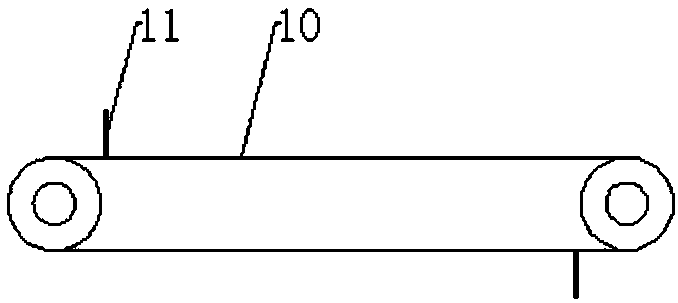

[0023] Such as figure 1 , figure 2 As shown, the color steel plate rock wool feeder includes an incoming conveyor belt 1, and two lifting devices arranged in front and back are arranged above the end section of the incoming conveyor belt 1. The lifting device includes a lifting device across the incoming conveyor belt 1. Frame 2, the leading screw 3 installed on the lifting frame 2, the lifting motor 4 connected with the leading screw 3 by a gear transmission mechanism, and the lifting plate 5 connected with the leading screw 3 by threads. Pushing devices moving along the front and rear directions are respectively arranged on the two lifting frames 2 upper ends, and the pushing devices include pushing cylinders 6 along the front and rear directions and push plates 7 that are rotated on the rod ends of the pushing cylinders 6 cylinders. One side of the lifting frame 2 is located below the push plate 7 and is provided with a separation cylinder 24 perpendicular to the conveyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com