Liquid distributor

A liquid distributor and liquid container technology, applied in the direction of the discharge device, etc., can solve the problems of complex structure of the liquid outlet valve, potential safety hazards, fracture failure of the handle end, etc., to avoid the risk of bending fracture, reliable opening and closing, and ensure structural safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

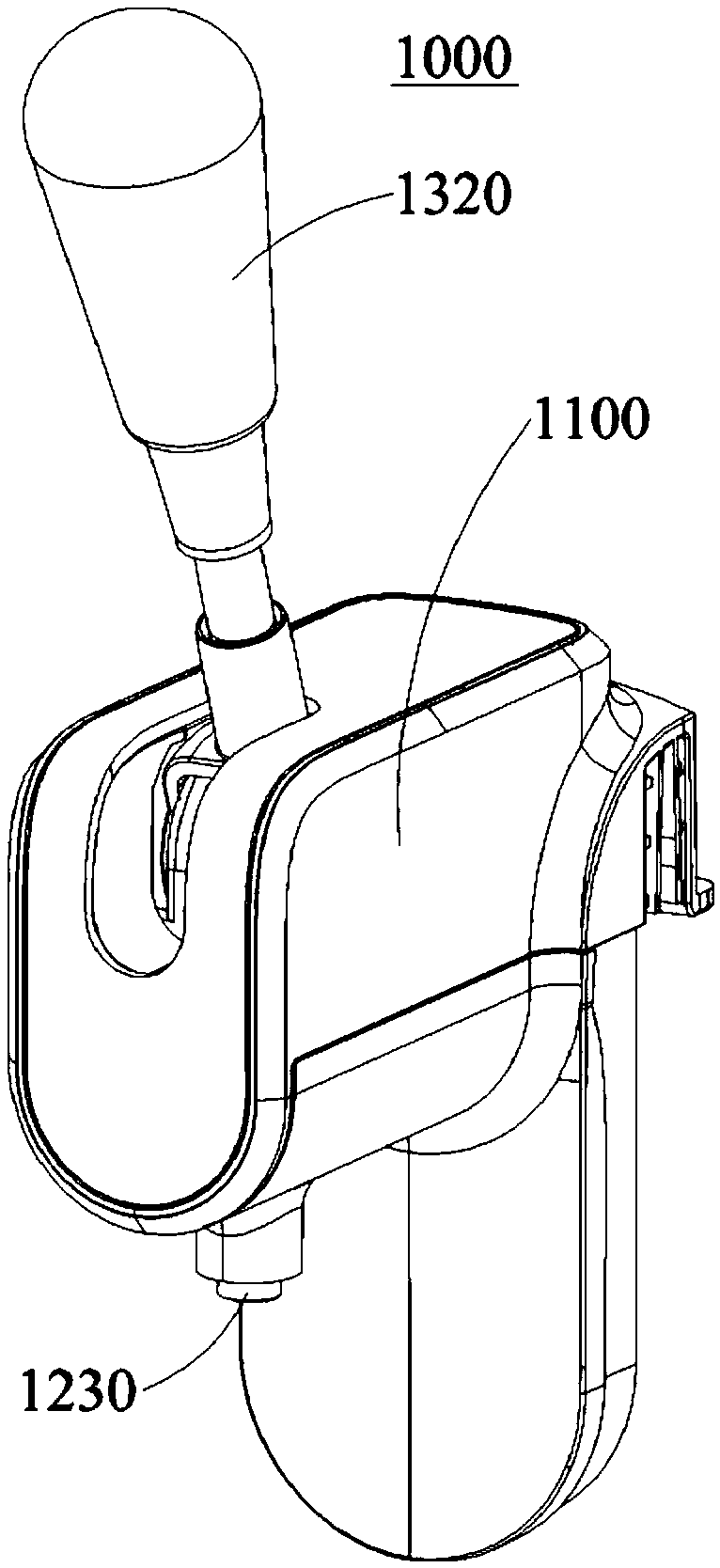

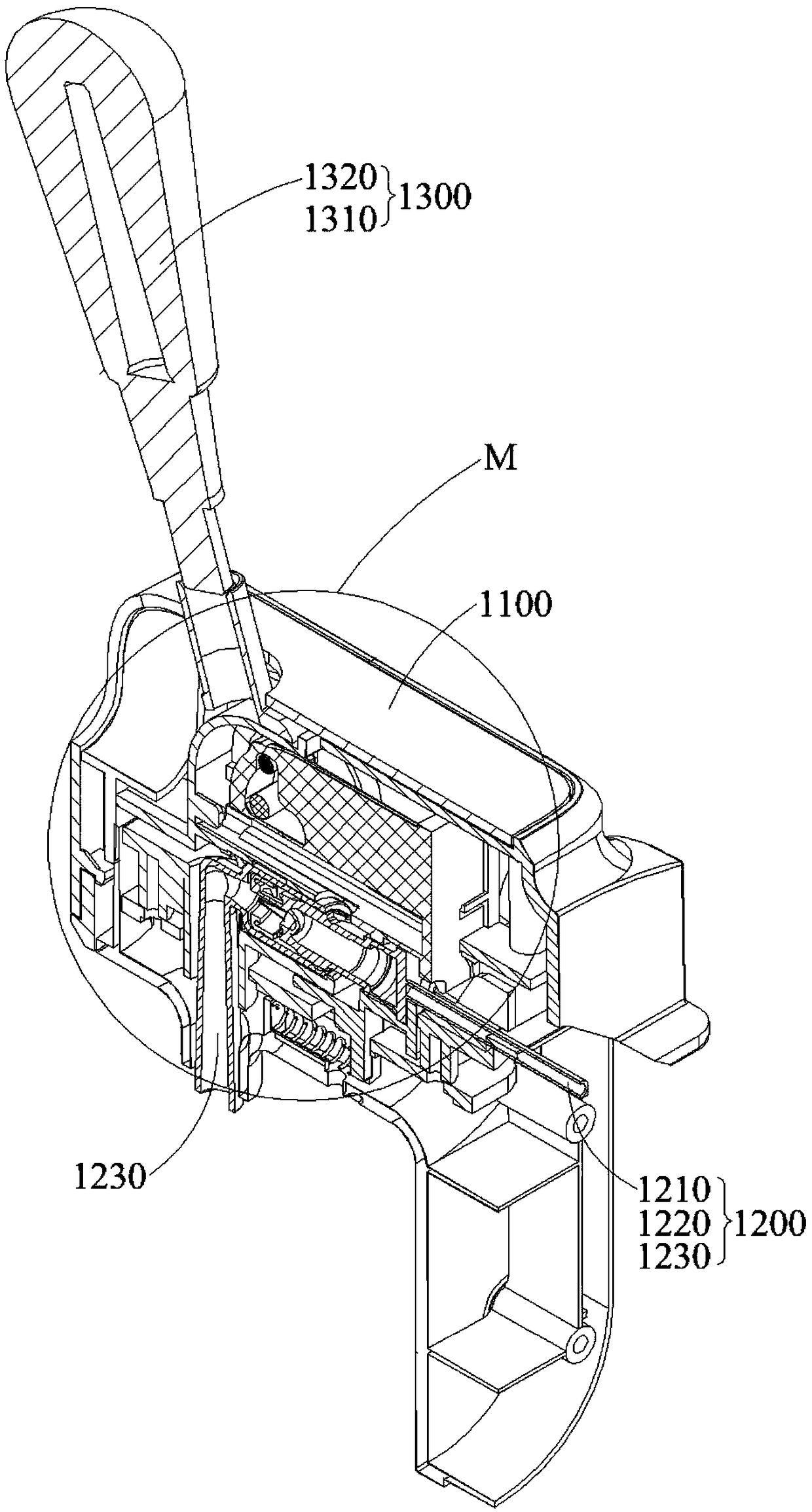

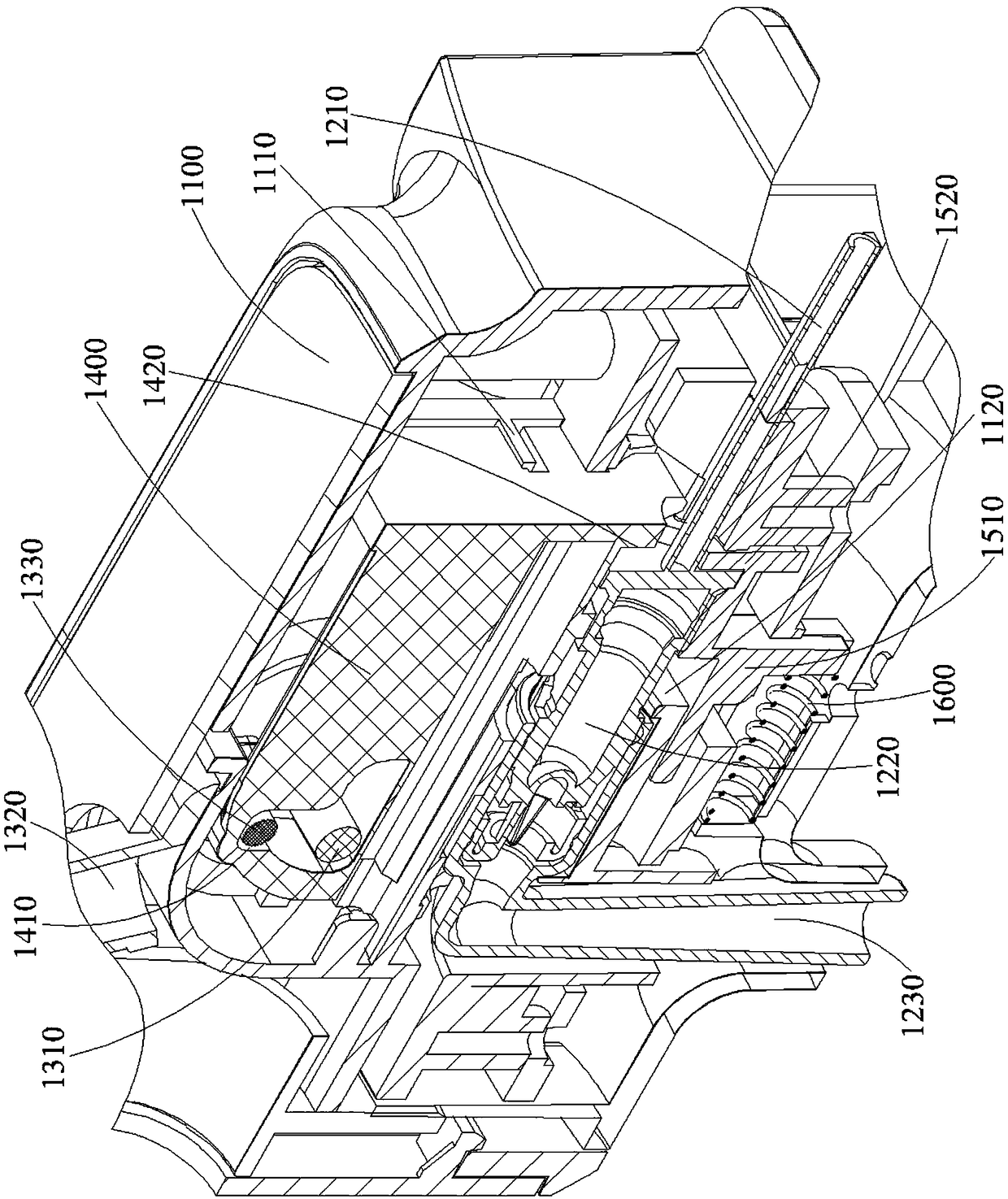

[0035] Please refer to Figure 1~3 , the present embodiment discloses a liquid dispenser 1000, the liquid dispenser 1000 includes a mounting base 1100, a push-pull valve 1200, a rotary input part 1300 and a movable transmission part 1400, which are used to provide a safe and reliable operation mode and realize the liquid container The reliable opening and closing and the smooth output of liquid.

[0036] Wherein, the installation base 1100 is used for connecting the liquid container, so that the liquid dispenser 1000 can be reliably held on the liquid container, so as to provide a reliable operation basis and form a stable liquid flow path. Liquid containers are used to load liquids, including barrels, tanks, boxes, or beverage machines with liquid bins and other types.

[0037] The push-pull valve 1200 is arranged on the installation base 1100, and is used to control the opening and closing of the fluid output of the liquid container. Specifically, the push-pull valve 1200 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com