Desulfurization and denitration method for boiler flue gas

A boiler flue gas, desulfurization and denitrification technology, applied in the field of desulfurization and denitrification, can solve the problems of high operating cost and secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

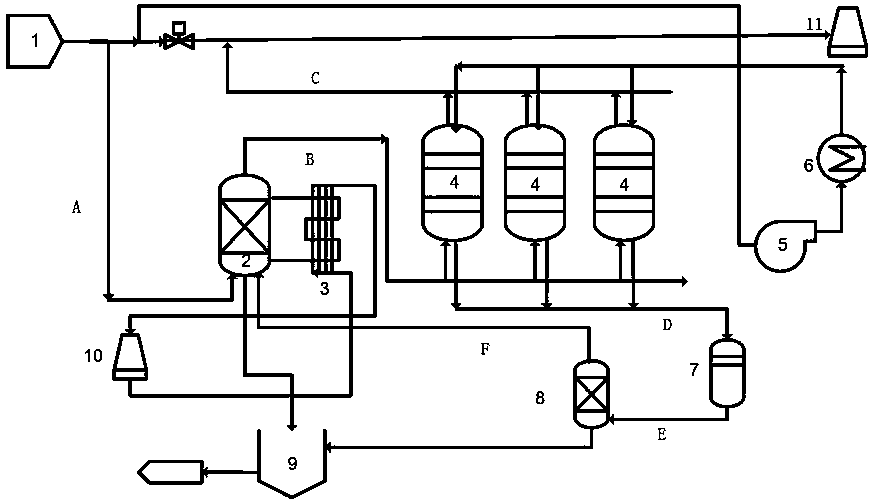

[0042] 160,000 cubic meters of flue gas at 145°C, with a nitrogen oxide content of 500mg / m 3 , the sulfide content is 200 mg / m 3 , enter the self-heat exchanger, and exchange heat with the cold flue gas entering the chimney, and the temperature is reduced to about 110°C; the flue gas at 110°C is cooled to 50°C by spraying, and the spray water is recycled, and after part of the waste water is neutralized, Biochemical removal system; the cooled flue gas passes through the demisting equipment and enters the adsorption tower; three 200m 3 ³ of adsorption towers, two open and one standby, each adsorption tower is filled with 120m 3 Microcrystalline materials, a total of 360m 3 Microcrystalline material mordenite; the adsorption tower has a diameter of 4.8 meters and a height of 12.0 meters; after the flue gas removes sulfides and nitrogen oxides, it enters the self-heat exchanger, and after heat exchange with the hot flue gas, it reaches above 100°C and enters the chimney emissi...

Embodiment 2

[0044] The specific implementation is as attached figure 1 The device process shown, 150,000 cubic meters of flue gas at 180°C, the nitrogen oxide content is 400mg / m 3 , the sulfide content is 100 mg / m 3 , enter the self-heat exchanger, and exchange heat with the cold flue gas entering the chimney, and the temperature is reduced to about 120°C; the flue gas at 120°C is cooled to 40°C by spraying, and the spray water is recycled, and after part of the waste water is neutralized, Biochemical removal system; the cooled flue gas passes through the demisting equipment and enters the adsorption tower; three 200m 3 The adsorption tower, two open and one standby, each adsorption tower is filled with 120m 3 Microcrystalline material, total 360 m 3 Microcrystalline material ZSM-5 molecular sieve; the specification of the adsorption tower is 4.8 meters in diameter and 12.0 meters in height; after the flue gas removes sulfide and nitrogen oxides, it enters the self-heat exchanger, and ...

Embodiment 3

[0046] The specific implementation is as attached figure 1 The device process shown, 140,000 cubic meters of flue gas at 140°C, the nitrogen oxide content is 450mg / m 3 , the sulfide content is 200 mg / m 3 , enter the self-heat exchanger, and exchange heat with the cold flue gas entering the chimney, and the temperature is reduced to about 110°C; the flue gas at 110°C is cooled to 50°C by spraying, and the spray water is recycled, and after part of the waste water is neutralized, Biochemical removal system; the cooled flue gas passes through the demisting equipment and enters the adsorption tower; three 200m 3 The adsorption tower, two open and one standby, each adsorption tower is filled with 120m 3 Microcrystalline material, total 360 m 3 Microcrystalline material ZSM-5 molecular sieve; the specification of the adsorption tower is 4.8 meters in diameter and 12.0 meters in height; after the flue gas removes sulfides and nitrogen oxides, it enters the self-heat exchanger, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com