Device and method for making vibration reduction clad sheet steel T-shaped peeling strength sample

A technology of peeling strength and clad steel plates, applied in the direction of measuring devices, mechanical devices, instruments, etc., to achieve the effects of stable experimental data, improved work efficiency, and good flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

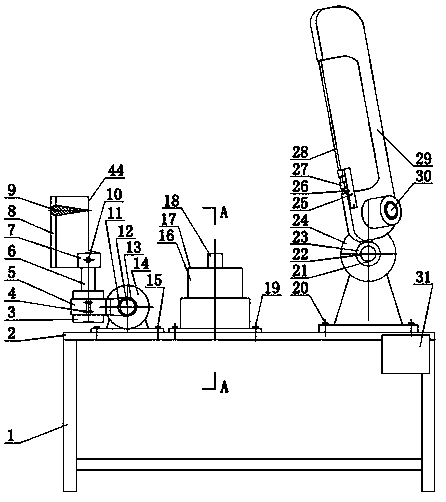

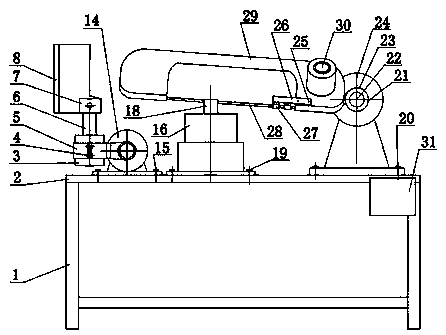

[0036]A device for making a T-shaped peel strength sample of a vibration-damping composite steel plate, comprising a bench 1, an electric control vise 16, a device for removing damping adhesive materials, a bending T-shaped device, and a display PLC controller 31, and the bench 1 includes The top surface 2 of the bench, the electric control vise 16, the device for removing the damping adhesive material and the bending T-shaped device are all fixed on the top surface 2 of the bench, and the electric control vise 16 is located between the device for removing the damping adhesive material and the bending T-shaped device. Between the folding T-shaped devices, the display PLC controller 31 is fixedly connected to the stand 1, and the display PLC controller 31 stores the control program for making the T-shaped peel strength sample of the vibration-damping composite steel plate;

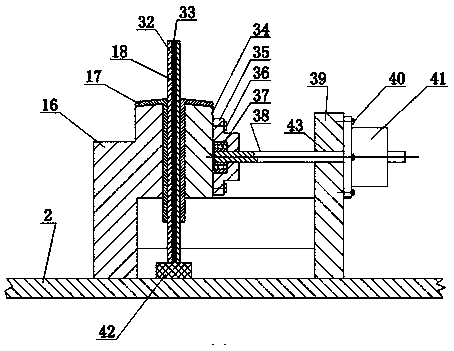

[0037] The electric control vise 16 includes a vise frame, a fixed jaw, a movable jaw 34 and a torque ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com