Test method of asphalt and coarse aggregate adhesiveness

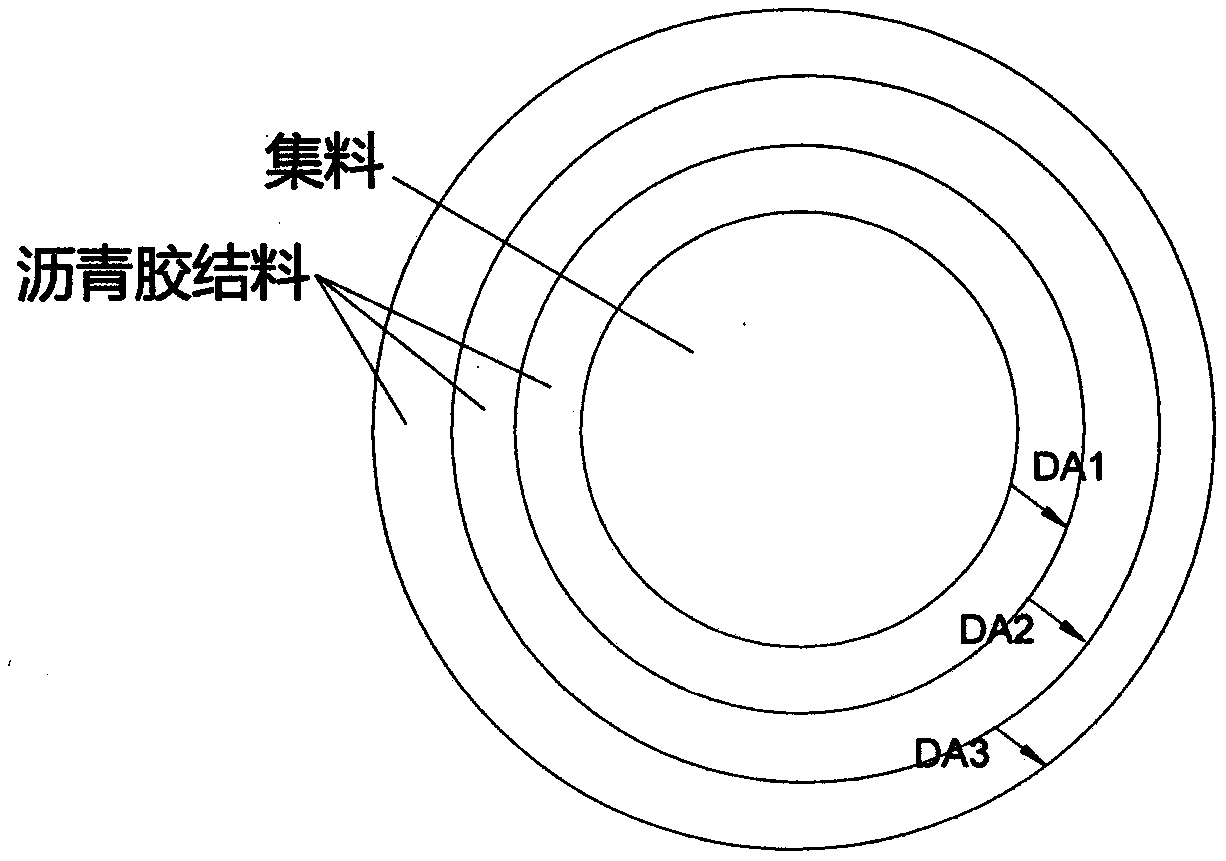

A test method and coarse aggregate technology, applied in the field of highway asphalt mixture test, can solve the problems of large test error, inability to accurately evaluate the quality of adhesion, and large influence of human factors, so as to reduce test error and quantify test results and objective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]This embodiment provides a test method for the adhesion between asphalt and coarse aggregate. The materials and instruments used include: 1. 5 limestone coarse aggregates with a diameter of 13.2 to 19 mm; 2. 350 g of matrix asphalt; 3. Analytical balance ;4. 3D area measuring instrument and software processing system; 5. Oven, the heating temperature can reach 200 ℃; 6. Thin wire; 7. 500ml beaker for holding asphalt; 8. 110L distilled water; 9. Self-made flushing water boiling Instrument; 10. Self-made bracket. 11. Asphalt density measurement related materials and instruments are based on the requirements in "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTG E20-2011) T0603-2011.

[0040] 1) Put 5 selected coarse aggregate samples into an oven for heating and drying;

[0041] 2) Take the heated coarse aggregate sample out of the oven and cool it to room temperature, then put the sample into the tray of the 3D area measuring instrument, click...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com