Exhaust gas combustion furnace and exhaust gas treatment equipment

A kind of waste gas treatment equipment, waste gas combustion technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

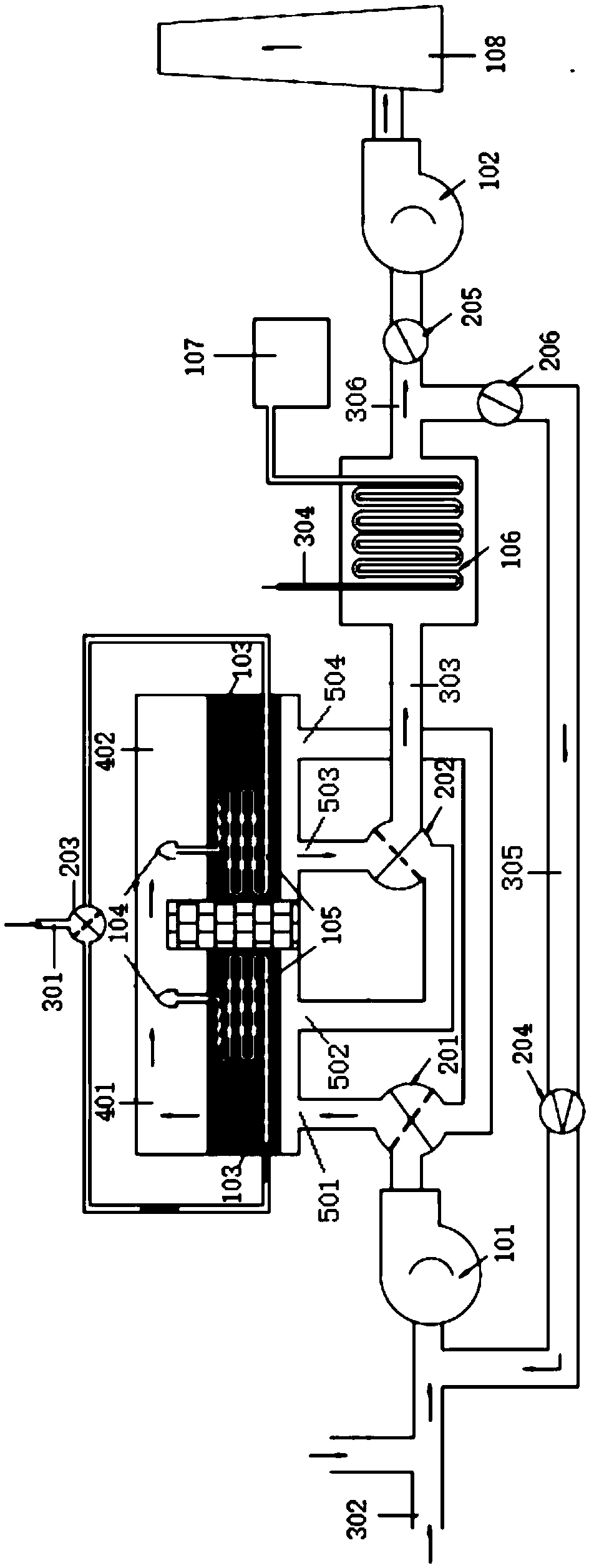

[0043] like figure 1 As shown, a waste gas combustion furnace proposed by the present invention includes a combustion chamber for burning and decomposing industrial waste gas. The combustion chamber includes a first combustion chamber 401 and a second combustion chamber 402. The upper part of the first combustion chamber 401 and the second combustion chamber The upper part of the combustion chamber 402 is connected; the heat storage body 103 is used to store heat, and the bottom of the first combustion chamber 401 and the bottom of the second combustion chamber 402 are equipped with a heat storage body 103; the gas preheating pipeline 105, the gas The air inlet of the preheating pipeline 105 is used to communicate with the external gas delivery pipeline 301, and each regenerator 103 is provided with a gas preheating pipeline 105, and the gas outlet of the gas preheating pipeline 105 extends out to burn chamber; and a burner 104, the gas outlet of each gas preheating pipeline 1...

Embodiment 2

[0049] like figure 1 As shown, the present invention proposes an exhaust gas treatment equipment, including the above-mentioned exhaust gas combustion furnace; the exhaust gas delivery pipeline 302 communicates with the first air inlet 501 and the second air inlet 504, and circulates alternately to the first combustion chamber 401, The second combustion chamber 402 transports industrial waste gas; the exhaust pipeline 303 communicates with the first exhaust port 502 and the second exhaust port 503, and circulates and alternately discharges the gas after the industrial waste gas combustion in the first combustion chamber 401, the second The gas after the combustion of industrial waste gas in the combustion chamber 402; the gas delivery pipeline 301 communicates with the gas preheating pipeline 105 in the first combustion chamber 401 and the gas preheating pipeline 105 in the second combustion chamber 402, and the cycle alternates Gas is delivered to the first combustion chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com