Construction method of high ground stress and basalt underground factory building cavern

A technology for underground powerhouses and high ground stress, which is applied to underground chambers, earthwork drilling, wellbore lining, etc. It can solve problems such as unfavorable surrounding rock stability and safety, looseness and collapse, and complex structures, so as to facilitate timely and rapid follow-up, reduce Effect of stress failure and reduction of blast disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0024] In conjunction with the accompanying drawings.

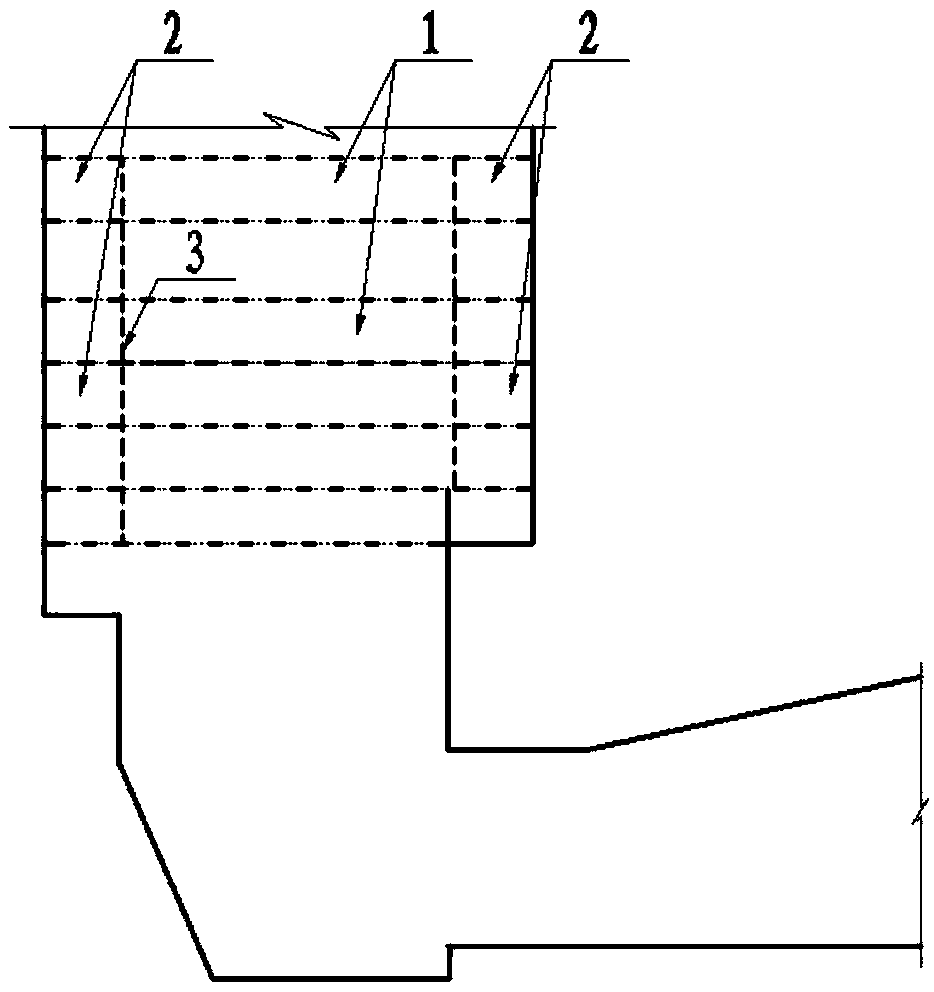

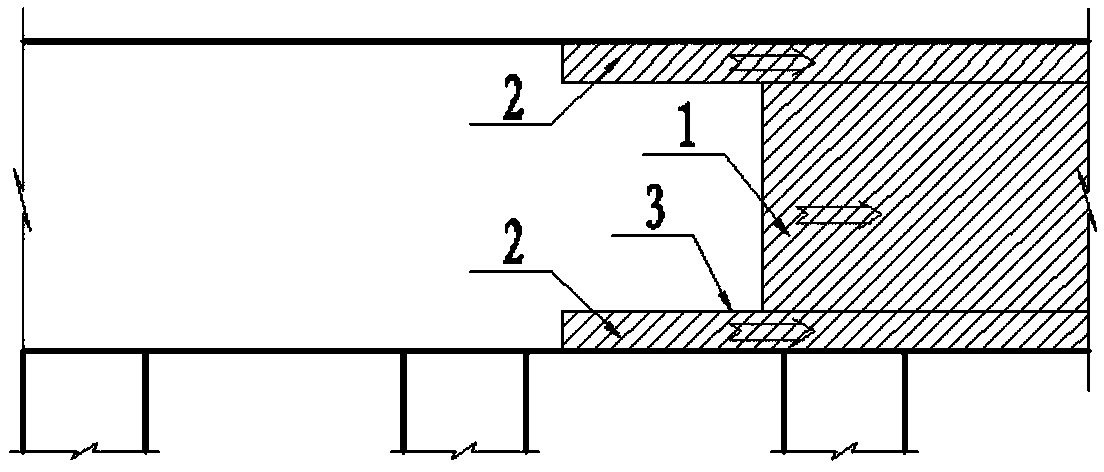

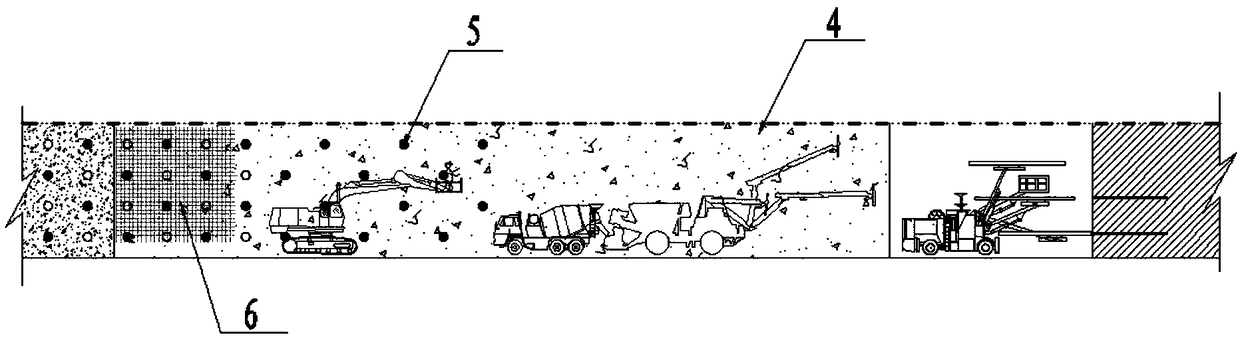

[0025] combine Figure 1 ~ Figure 3 , the following is an illustration of a specific excavation construction of an underground powerhouse cavern. The powerhouse is constructed under high ground stress and basalt geological conditions. The excavation of the protective layer includes the following steps:

[0026] 1) For the caverns of large-span underground powerhouses, adopt the method of horizontal pushing of layers in the middle + reserved excavation of protective layers on both sides, such as figure 1 and figure 2 As shown, the first layer of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com