A natural gas hydrate mining sediment cyclone separator

A cyclone separator and hydrate technology, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well parts, etc., to achieve the effects of low processing cost, wide application range, and enhanced internal swirl strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

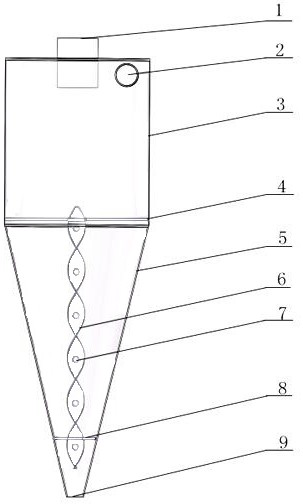

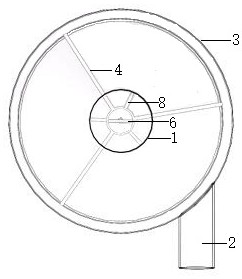

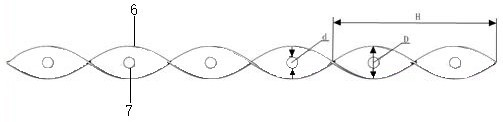

[0028] In order to improve the sediment separation efficiency in the process of natural gas hydrate exploitation, reduce the loss of natural gas hydrate and avoid the formation of air resistance in the separator by natural gas, this embodiment discloses a sediment cyclone separator for natural gas hydrate exploitation, specifically Organization see Figure 1-5 , the body of the cyclone separator includes a cylindrical shell 3 above and a conical shell 5 below, wherein the cylindrical shell is 285 mm high, the shell diameter is 250 mm, the conical shell is 463 mm high, and the cone angle is 15°. An overflow port 1 is provided on the top of the cylinder body 3, and a feed port 2 is provided on the side wall. The diameter of the overflow port is 70 mm, and the total length of the overflow pipe is 85 mm. is 65 mm, the diameter of the feed inlet is 40 mm, and the length is 50 mm; at the bottom of the conical cylinder 5, there is an underflow opening 9, and the diameter of the under...

Embodiment 2

[0035] In order to illustrate the impact of the flow hole on the link in the sediment cyclone separator for natural gas hydrate exploitation disclosed in Example 1 on the change in resistance, this embodiment did separator pressure drop experiments at different flow rates. The result is as Image 6 As shown, it can be seen from the figure that within the given flow range, the pressure drop of the separator without flow holes on the link is about 9.5% higher than that of the separator with flow holes.

Embodiment 3

[0037] Figure 7Shown is the comparison result of the separation efficiency of the cyclone separator disclosed in Example 1 and the separation efficiency of the traditional hydrocyclone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com