Latex-like cotton and preparation method thereof

A milk-cotton, mass-percent technology, applied in the field of materials, can solve the problems of easy weathering of latex products, affecting product quality and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

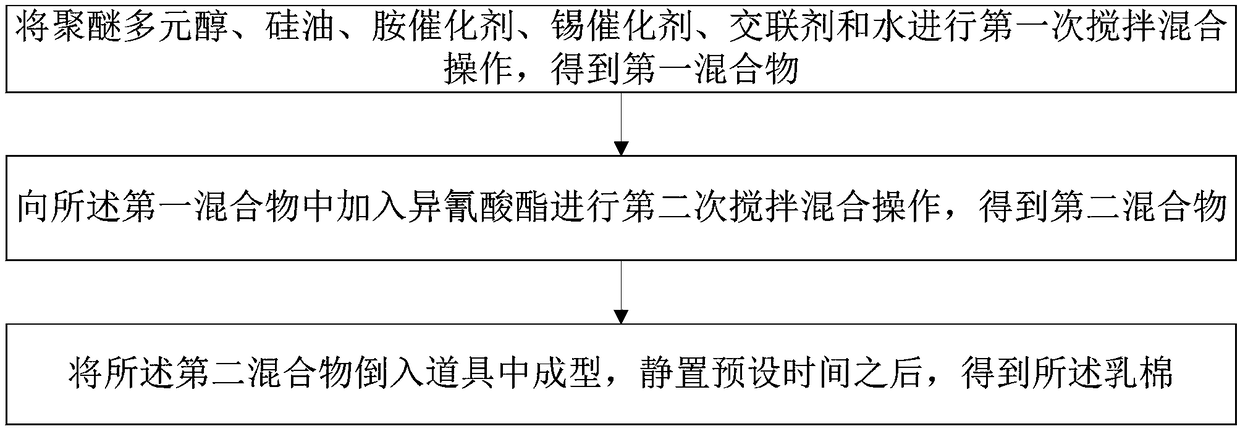

[0037] The present invention also provides a method for preparing milk cotton, the milk cotton is the milk cotton as described in any of the above embodiments, please refer to figure 1 , the preparation method of described milk cotton comprises the steps:

[0038] S110: Stir and mix the polyether polyol, silicone oil, amine catalyst, tin catalyst, crosslinking agent and water for the first time to obtain a first mixture;

[0039] In this embodiment, the temperature of the first stirring and mixing operation is 18°C-26°C. In this way, the various components can be mixed well.

[0040] In one of the embodiments, the step 110 is specifically: put polyether polyol, silicone oil, amine catalyst, tin catalyst, crosslinking agent and water into the stirred tank for the first stirring and mixing operation to obtain the first mixture ; Thus, by putting polyether polyol, silicone oil, amine catalyst, tin catalyst, crosslinking agent and water into the stirring tank, the stirring and m...

Embodiment 1

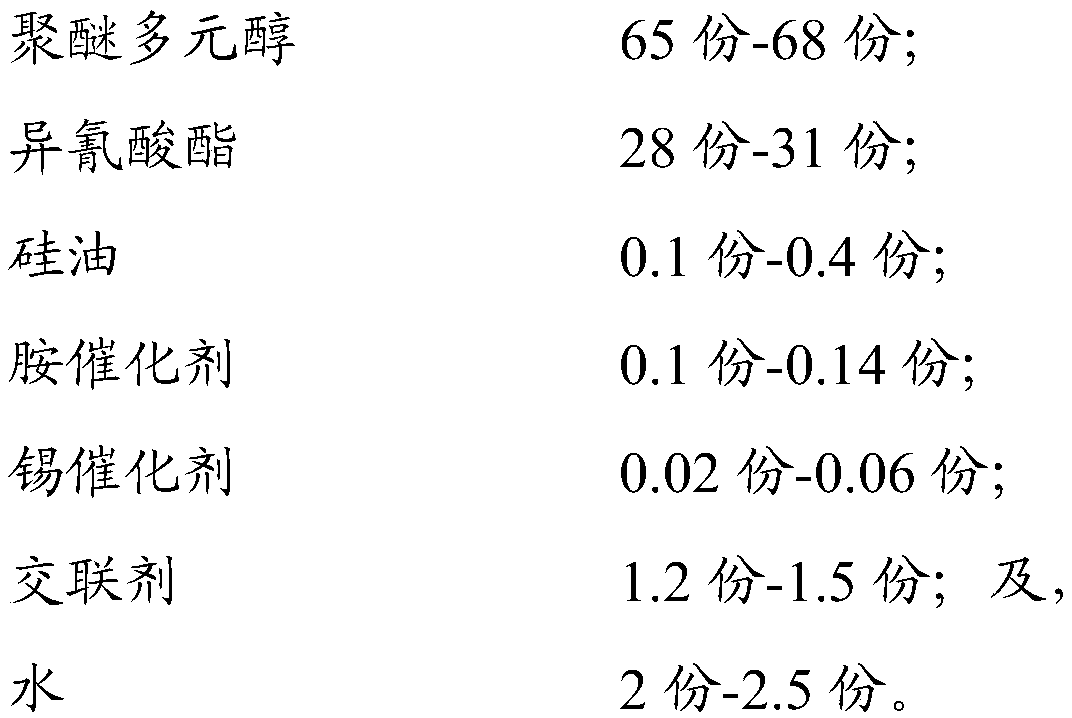

[0049] A kind of milk cotton comprises each component of following mass parts:

[0050]

[0051] Among them, the crosslinking agent is zinc chloride, the tin catalyst is stannous octoate, and the amine catalyst is tetramethylethylenediamine, wherein tetramethylethylenediamine is an aqueous solution with a concentration of 2%, that is, the amine catalyst is tetramethylethylenediamine. An aqueous solution of ethylenediamine at a concentration of 2%. Water is deionized water.

[0052] Milk cotton preparation method is as follows:

[0053] Put polyether polyol, silicone oil, amine catalyst, tin catalyst, crosslinking agent and water into the stirred tank for the first stirring and mixing operation to obtain the first mixture; during the first stirring and mixing operation, control the temperature of the stirring tank The temperature is 22 degrees Celsius, the stirring speed is 550 rpm, and the stirring time is 3 minutes.

[0054] Add isocyanate to the first mixture to carry ...

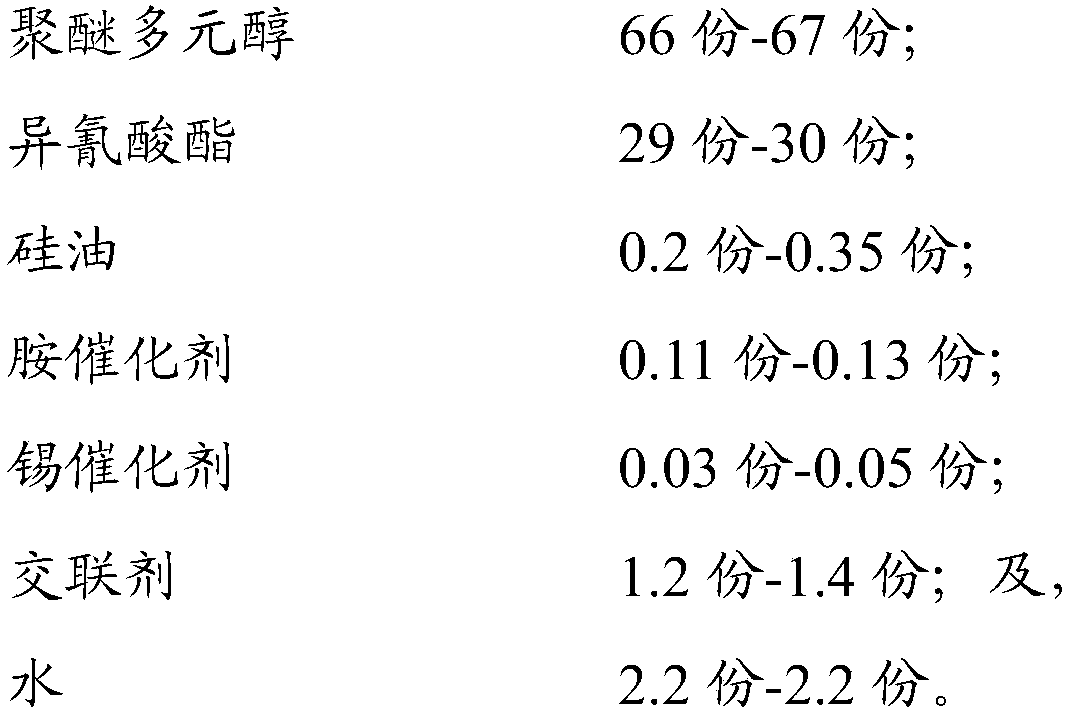

Embodiment 2

[0057] The difference from Example 1 is that the temperature of the first stirring and mixing operation is 17 degrees Celsius, and the temperature of the second stirring and mixing operation is 17 degrees Celsius.

PUM

| Property | Measurement | Unit |

|---|---|---|

| resilience | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com