Construction method of a bolt-type lifting ring beam

A construction method and plug-in technology, which can be used in manufacturing tools, metal processing equipment, welding equipment, etc., and can solve problems such as poor coordination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

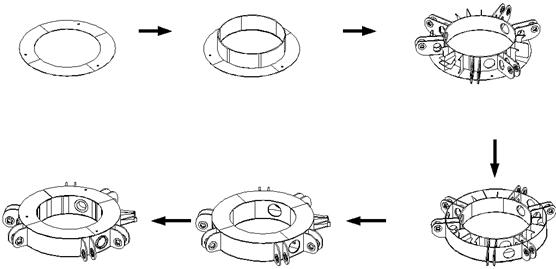

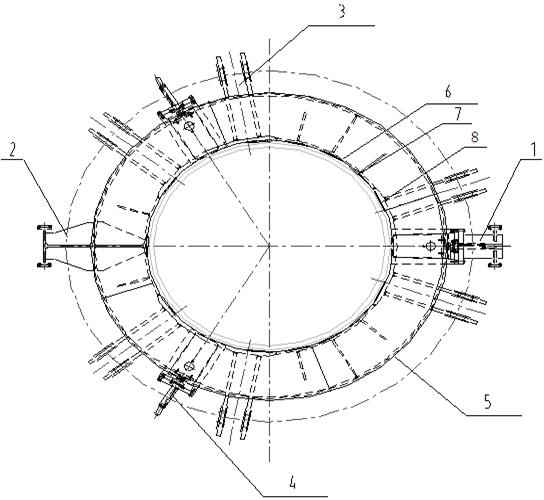

[0025] A construction method of a bolt-type lifting ring beam, the construction technology of the lifting ring beam mainly includes making upper and lower cover plates, making anti-rotation device 2, making lug plate 3 and making shaft sleeve 4, and then proceeding to general assembly, the present invention The construction technology of the lowering ring beam firstly forms the overall structure of the lifting ring beam, and then carries out the internal continuous welding of the ring beam. The specific construction steps are as follows: figure 1 Shown below:

[0026] Step 1, the construction of the lifting ring beam box: first splice the 4 arcs made into a complete lower cover plate on the pyrotechnic platform, then fix the lower cover plate on the tire frame to mark the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com