Rigid-flexible exoskeleton hand function rehabilitation device manufactured by flexible material 3D printing

A flexible material and 3D printing technology, applied in additive processing, passive exercise equipment, physical therapy, etc., can solve the problems of rigid equipment structure complexity, finger abduction assistance, poor applicability, etc., and achieve safe and easy to implement, Easy to wear and comfortable, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

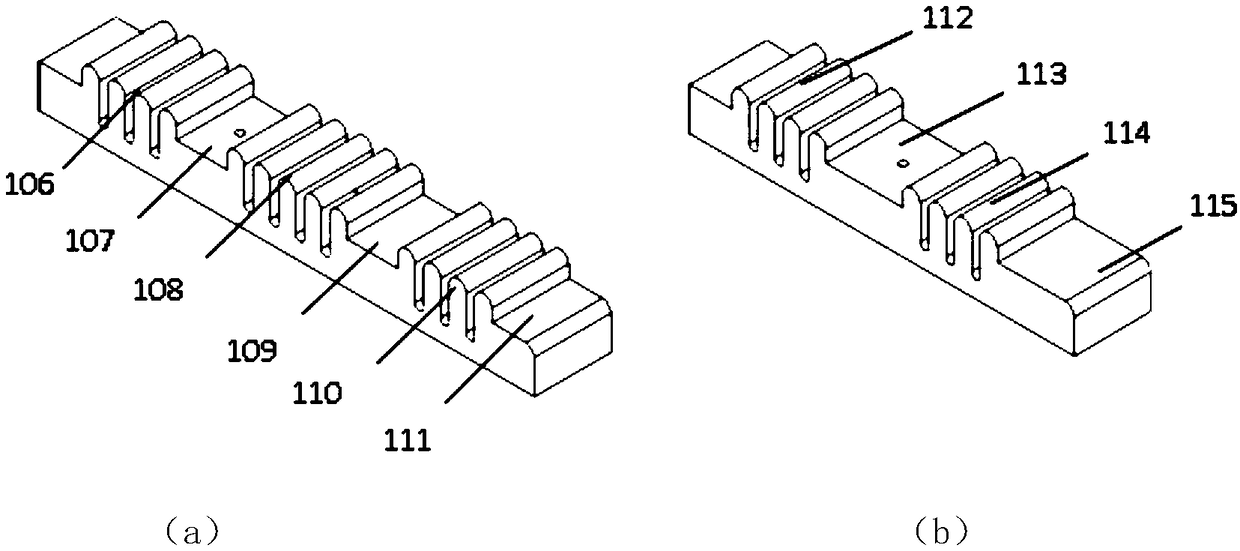

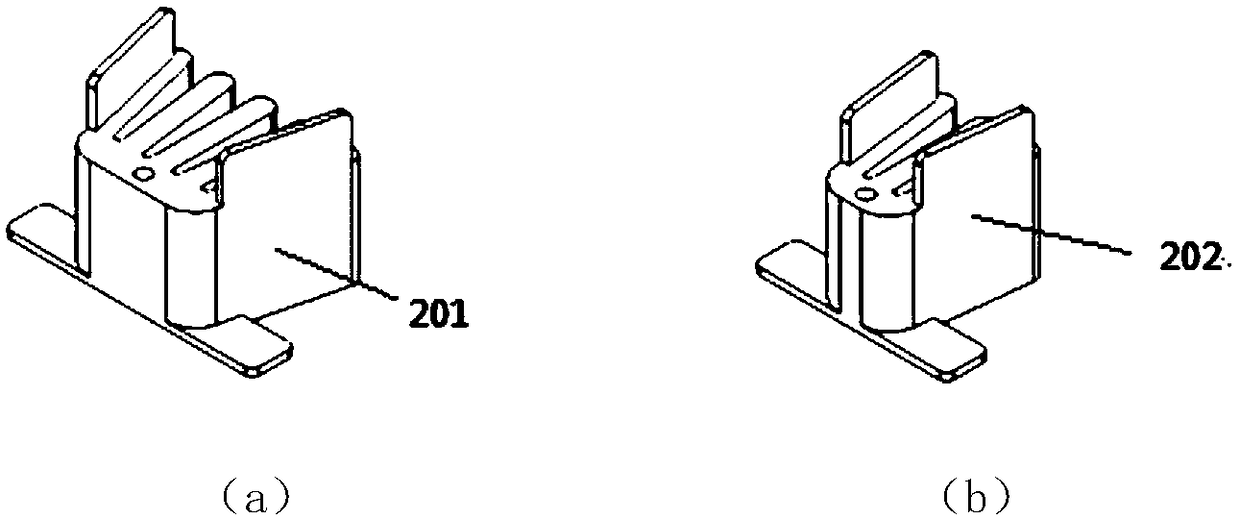

[0028] refer to figure 1 , a rigid-flexible exoskeleton hand function rehabilitation device made of 3D printed flexible materials, including a bending actuator 1, the bending actuator 1 is pasted on the glove module 3 by Velcro, and the abduction actuator 2 is fixed on the glove module by sewing 3, the glove module 3 is worn on the patient's hand, the bending actuator 1 and the abduction actuator 2 are connected to the control system and the air compressor through the air pipe, and the bending actuator 1 and the abduction actuator 2 are both Manufactured by 3D printing, the flexible material used for 3D printing is NinjaFlex 85A TPU.

[0029]The bending actuator 1 includes an exoskeleton index finger bending actuator 101 covering exoskeleton fingers, an exoskeleton middle finger bending actuator 102, an exoskeleton ring finger bending actuator 103, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com