Operating module for motor vehicle

A technology for motor vehicles and motor vehicle transmissions, applied in the direction of convenient operation, components with teeth, electrical components, etc., can solve problems such as target conflicts, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

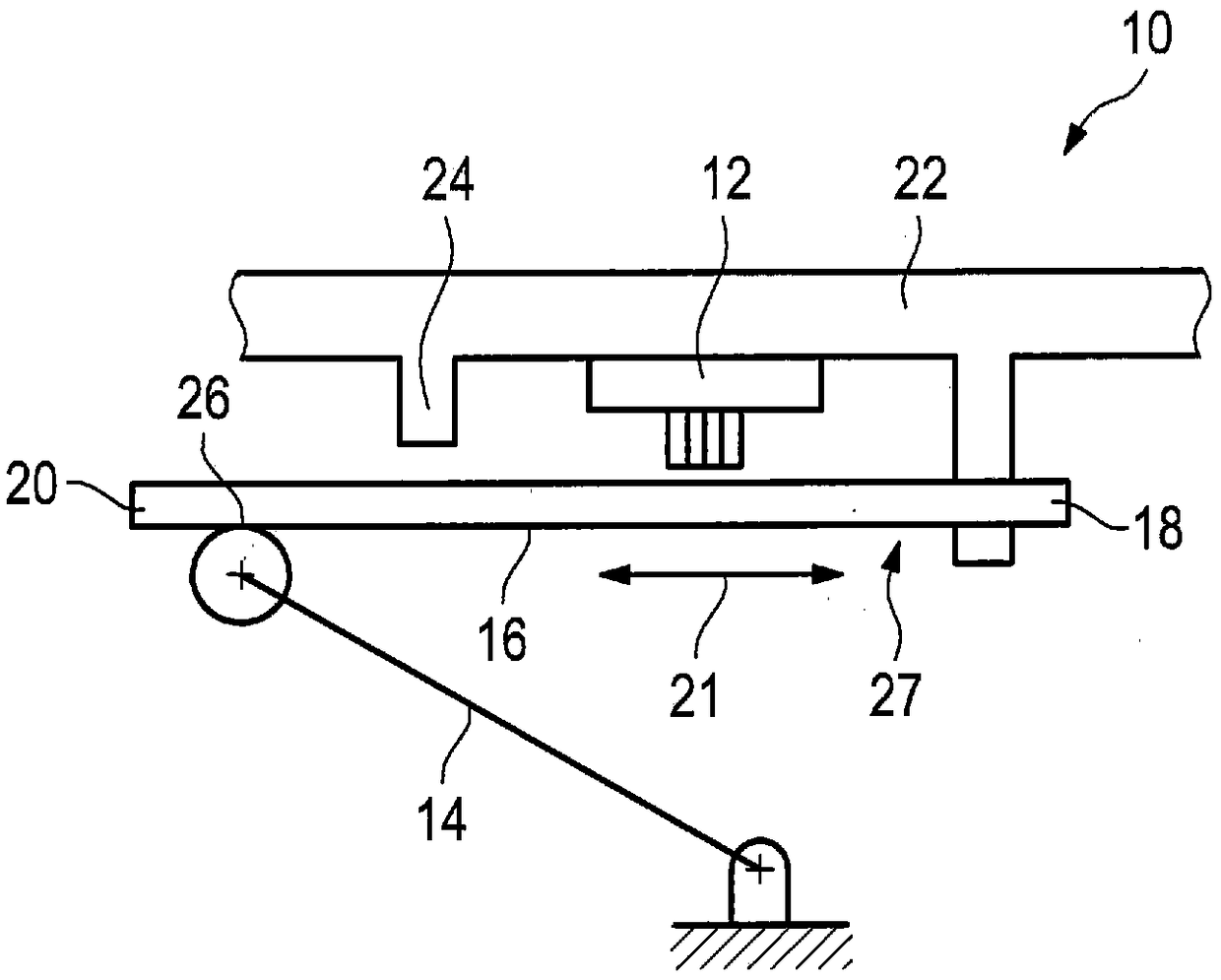

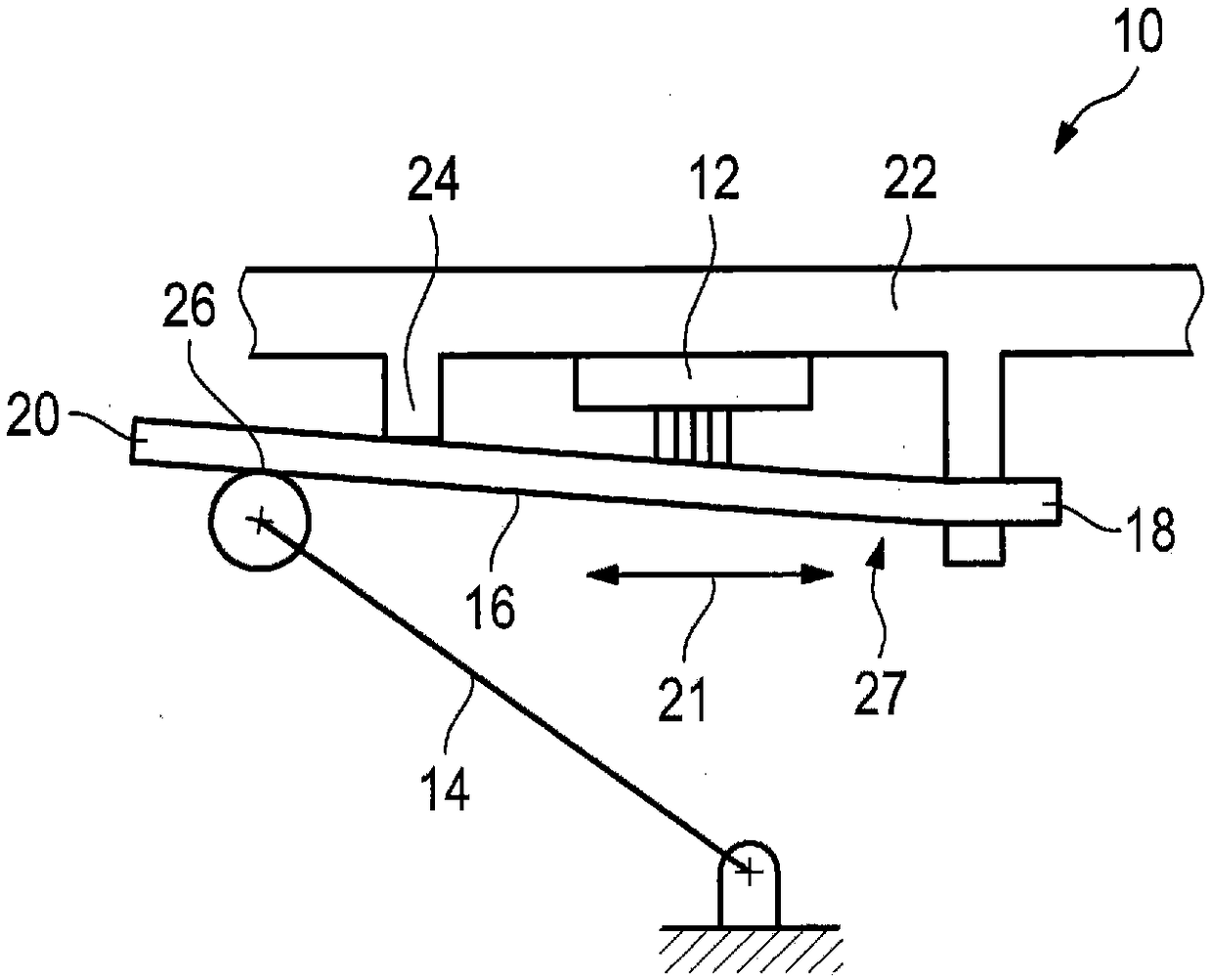

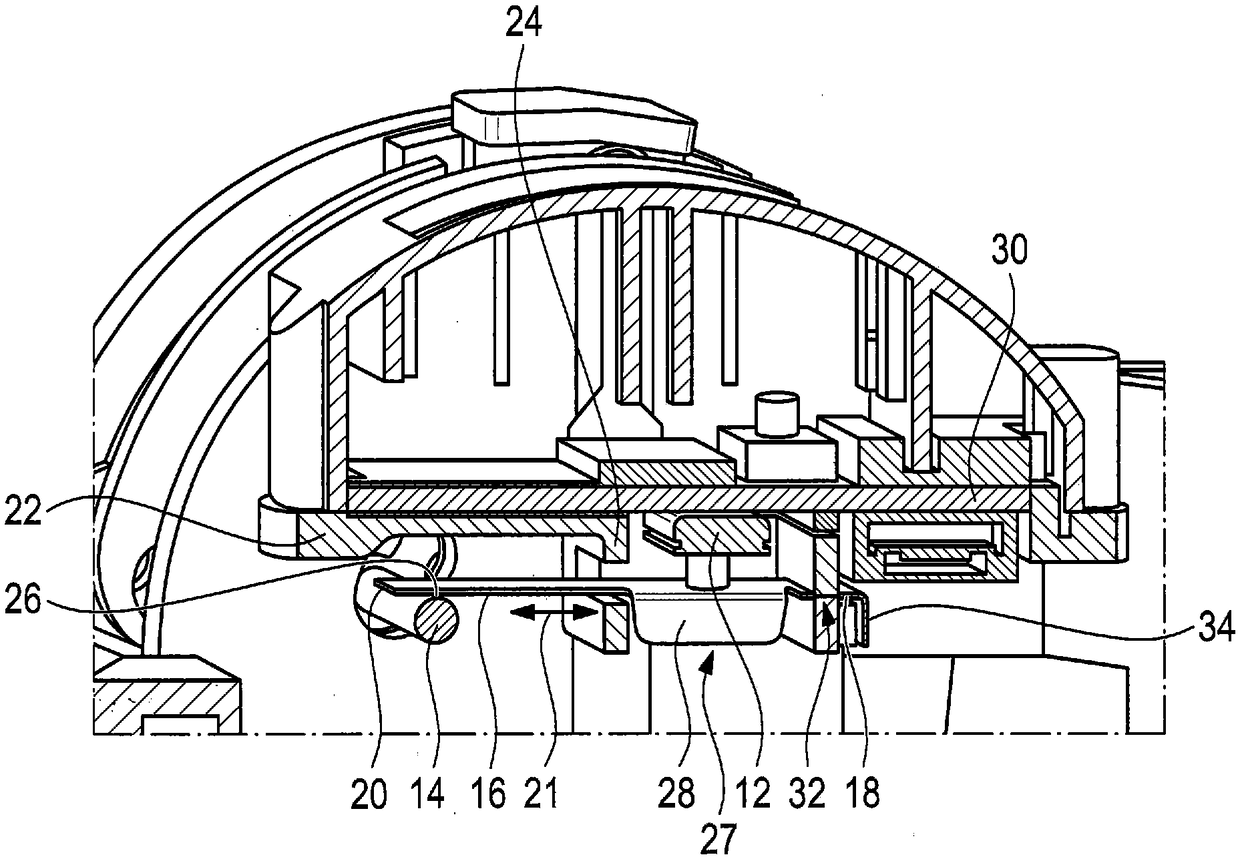

[0030] figure 1 An operating assembly 10 is shown in which an electrical switching element 12 , a microswitch in the illustrated embodiment, is actuated via a first lever 14 and a second lever. The second lever is a leaf spring 16 comprising a fixed clamping end 18 and a free end 20 .

[0031] In the embodiment shown, the first lever 14 can be integrally formed on a shift stage selection element arranged, for example, in the center console of the motor vehicle or on a shift paddle arranged on the steering wheel of the motor vehicle.

[0032] The leaf spring 16 extends in the direction indicated by the arrow 21 .

[0033] In this case, the electrical switching element 12 is supported in a carrier element 22 in which the fixed clamping end 18 of the leaf spring 16 is supported.

[0034] Furthermore, a stop 24 is arranged on the carrier element 22 . The stop is integrally connected to the carrier element 22 and is embodied as a protrusion. The stop portion 24 is used to limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com