Leading edge protection of a wind turbine blade

A wind turbine blade and leading edge technology is applied in the field of preparing wind turbine blades with leading edge protection, which can solve the problems of wet inclusions, air inclusions, weakened coating strength and corrosion resistance, etc., so as to improve corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

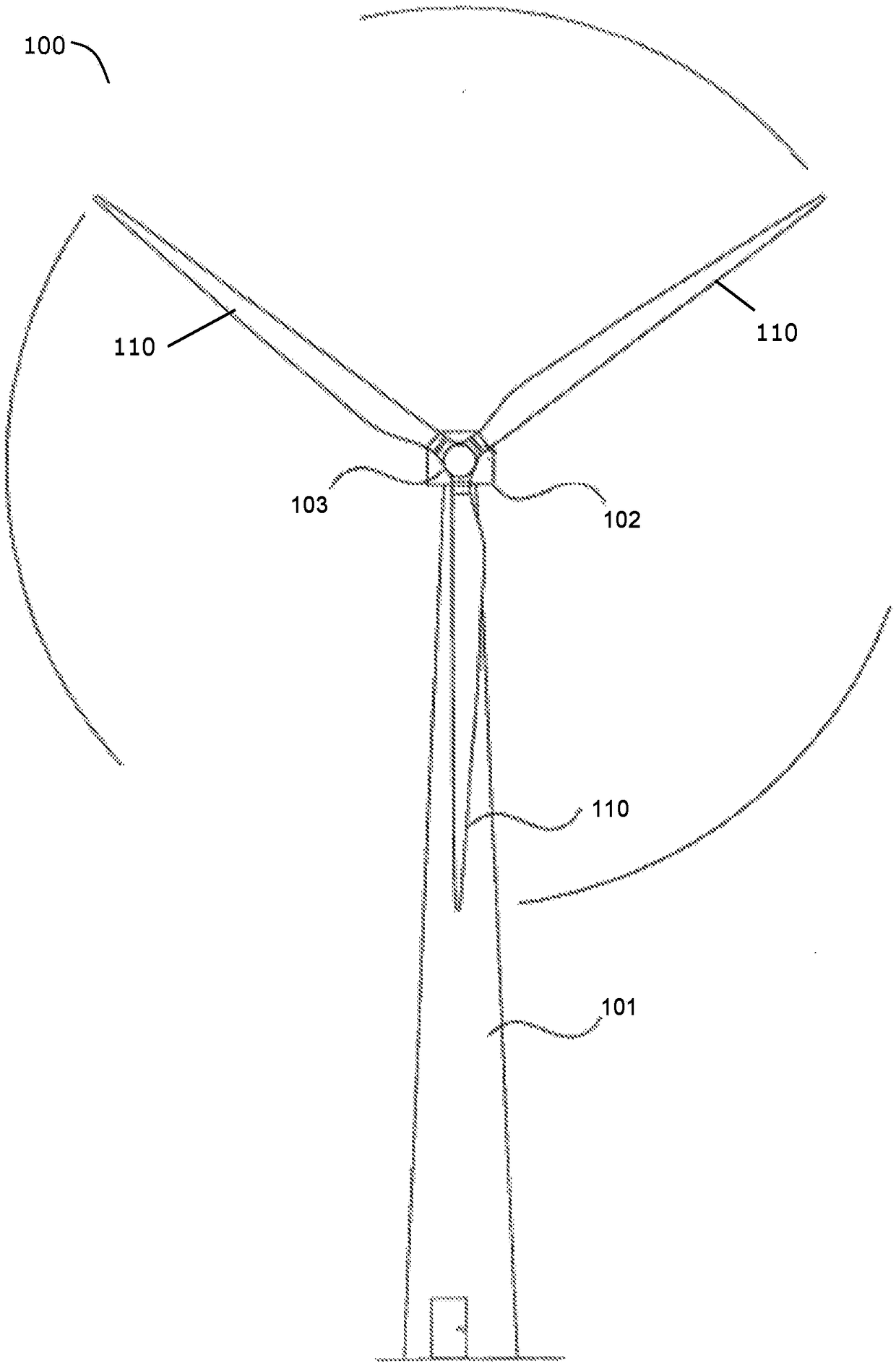

[0042] figure 1 A wind turbine 100 is shown, which includes a tower 101, a nacelle 102 on top of the tower, and nacelle housing machine parts such as gearboxes, generators (not shown), and the like. At one end of the nacelle, the hub portion 103 supports a plurality of wind turbine blades 110.

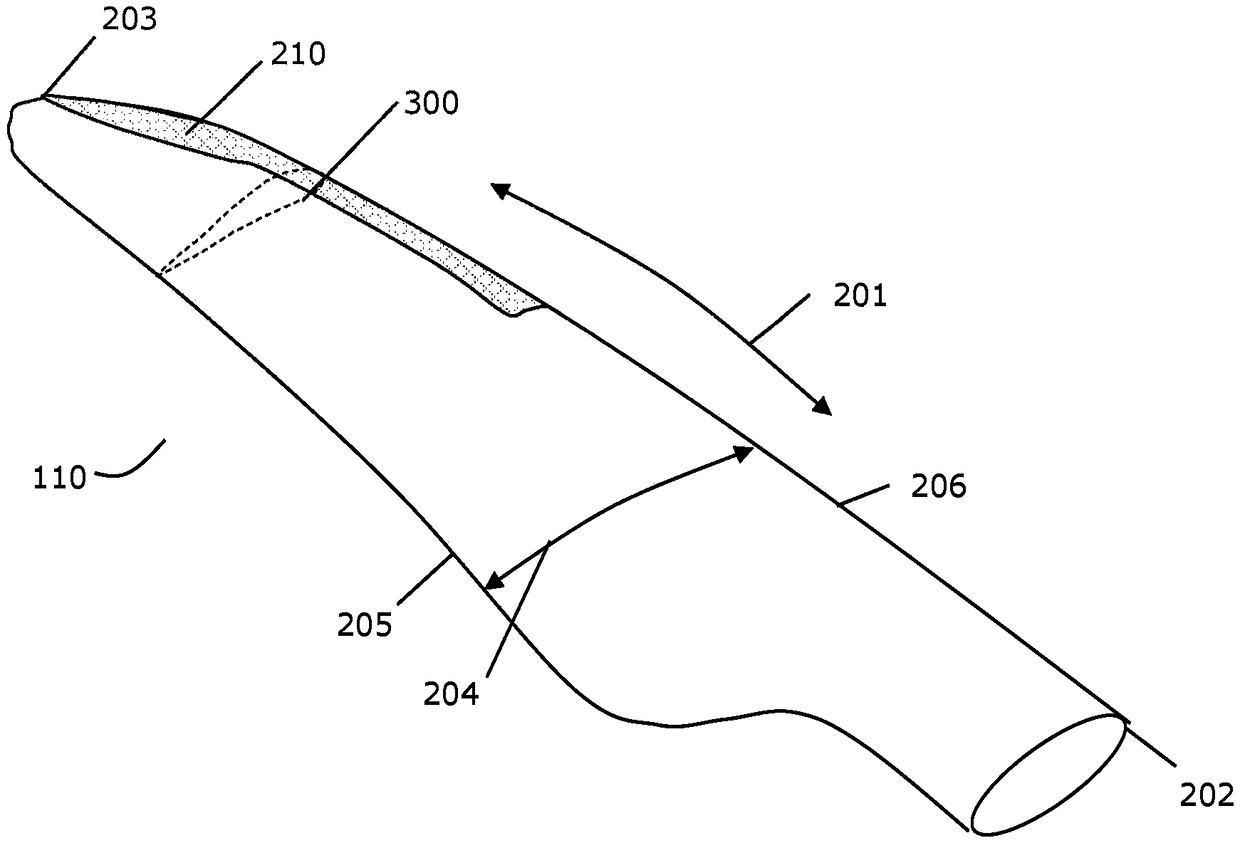

[0043] figure 2 A wind turbine blade 110 is shown, which extends a length 201 between the root end 202 and the tip end 203 of the blade and a width between the trailing edge 205 and the leading edge 206 as indicated by the arrow 204. The outer surface portion 210 of the wind turbine blade covers a part of the leading edge 206 and is provided with leading edge protection according to the present invention.

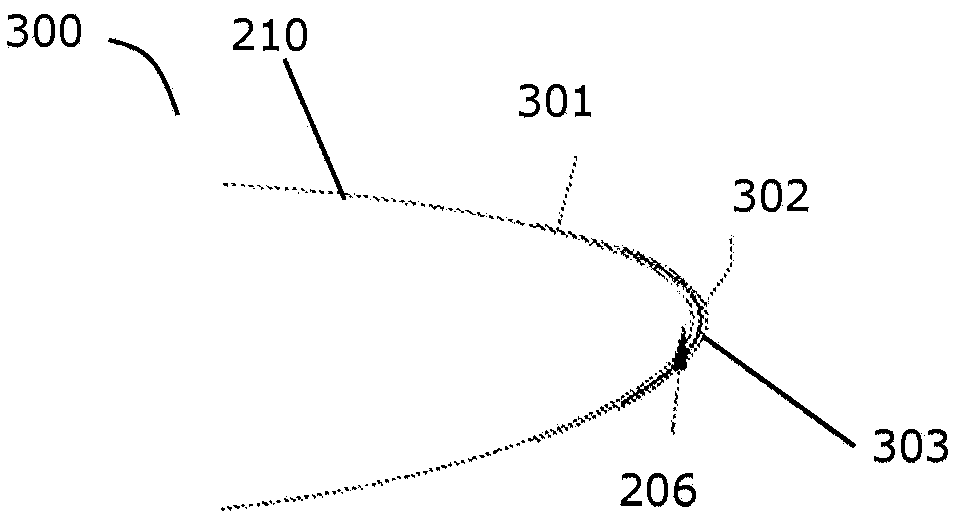

[0044] image 3 A part of the wind turbine blade 101 seen in the cross-sectional view is shown, and this part corresponds to figure 2 The outline 300 shown in. The outer surface portion or outer surface portion 210 of the blade covers and extends over the leading edge 206 of the blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com