Method and device for producing a shaped part

A deformed part and circular technology, applied in the field of manufacturing deformable parts and devices, can solve the problems of time consumption and cost consumption, and achieve the effects of reduced friction loss, soft deformation, and reduced frictional heat generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

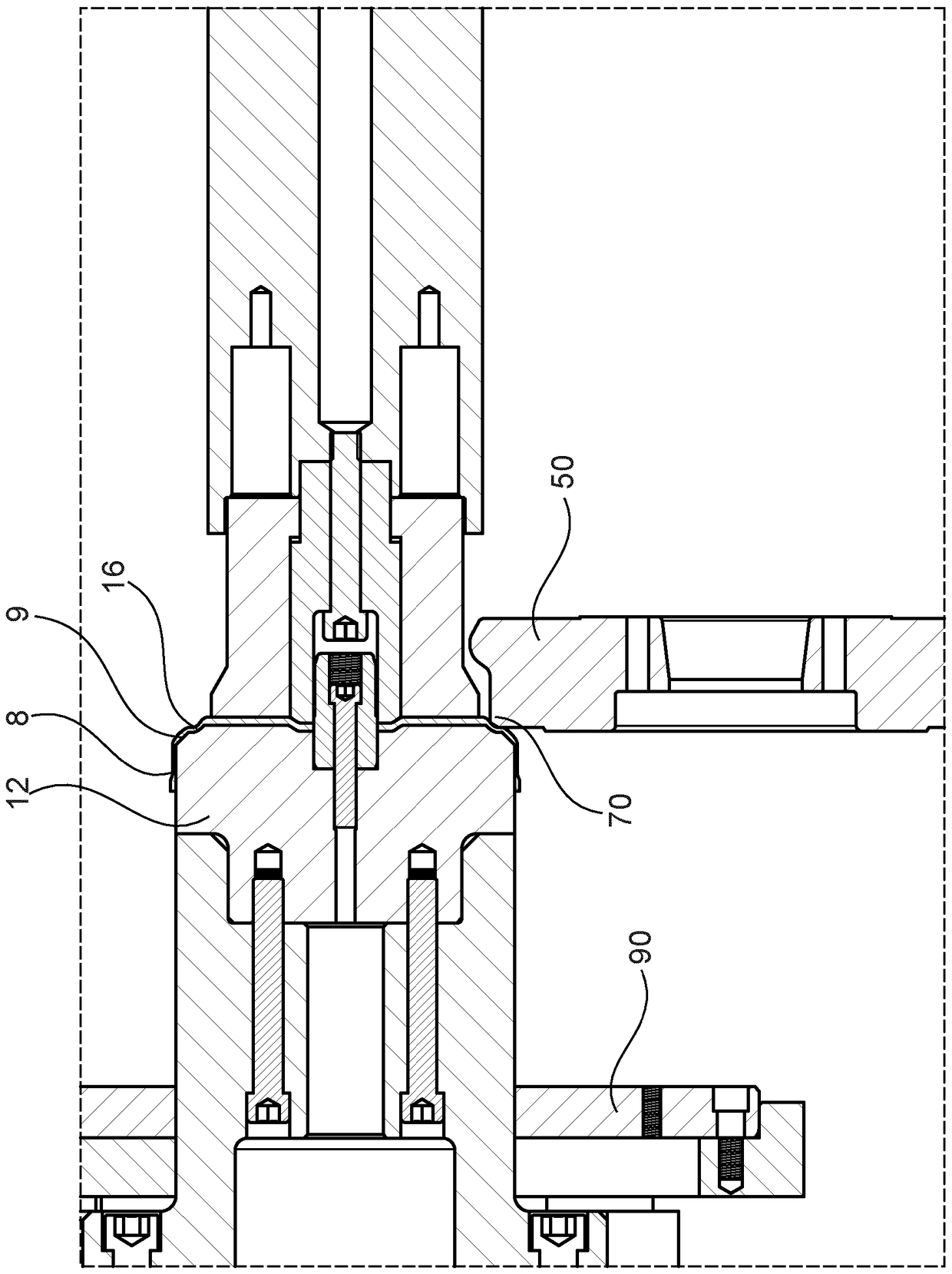

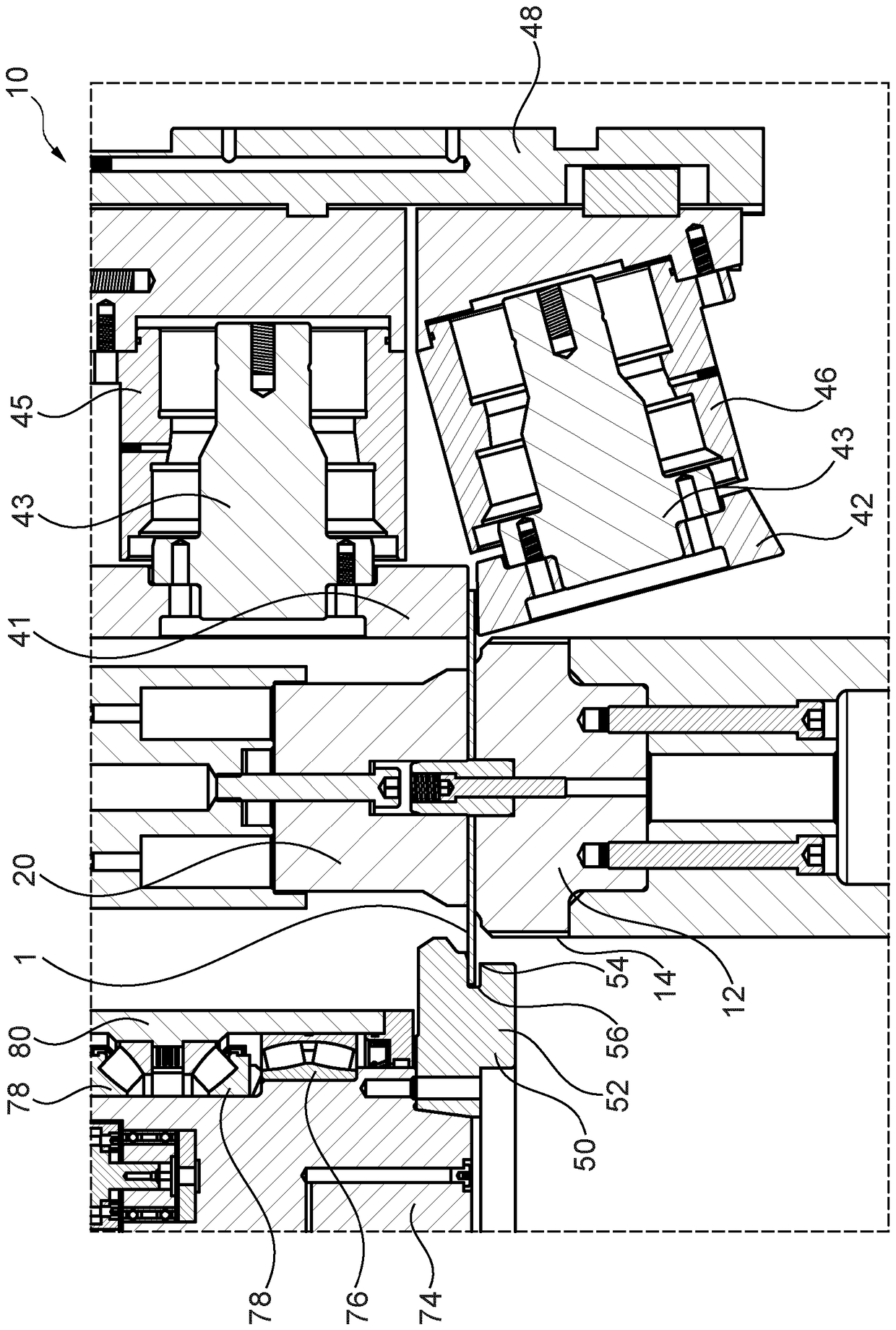

[0034] according to figure 1 In the case of the device 10 according to the invention, a rotationally symmetrical circular blank 1 of sheet material is clamped centrally and axially between the spinning die 12 and the counter-carrier 20 for the production of the deformed part. The clamped round blank 1 is set in rotation by a rotary drive (not shown).

[0035] Compression rollers 50 with roller base bodies 52 are fed radially from the outside at the outer edge of the round blank 1 . A compression region 54 with a surrounding shaped groove 56 is formed in the middle section on the roller base body 52 . The outer edge of the circular blank 1 is housed in a shaped groove 56 which presets the outer contour of the area of the circular blank to be compressed.

[0036] The roller base body 52 is seated on a compression roller shaft 74 , which is rotatably mounted in a bracket 80 via a radial bearing 76 and an axial bearing assembly 78 . The support by means of the radial bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com