Production of chemical reactors

A chemical reactor and structured technology, applied in the field of chemical reactors, can solve the problem of low separation efficiency and achieve good separation ability and edge accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

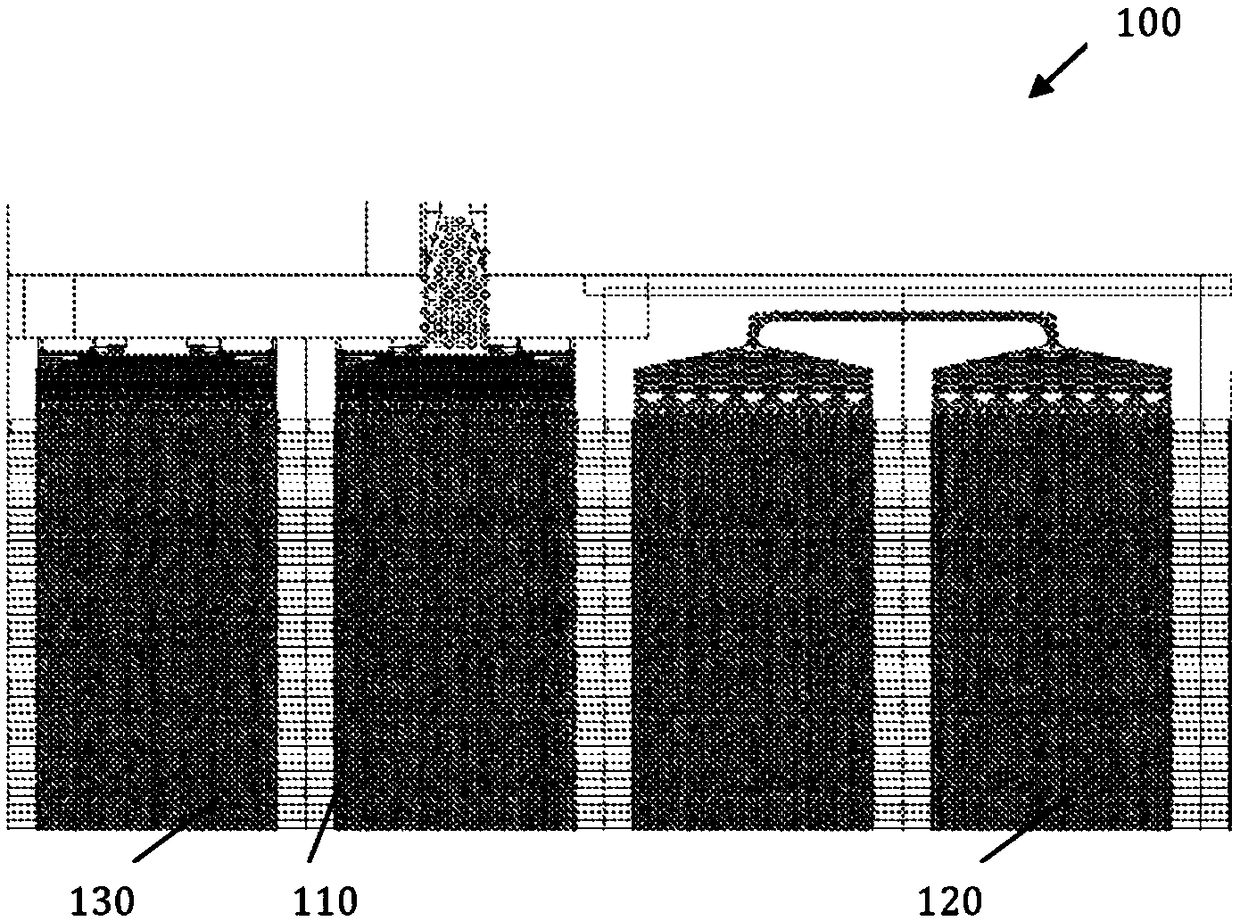

Image

Examples

Embodiment Construction

[0045] While the invention will be described with reference to particular embodiments and with reference to certain drawings, the invention is not limited thereto but only by the claims.

[0046]It should be noted that the terms 'having' and 'comprising' as used in the claims should not be interpreted as being limited to the means listed thereafter; they do not exclude other elements or steps. Accordingly, it should be interpreted as specifying the presence of said features, integers, steps or components referred to, but not excluding the presence or addition of one or more other features, integers, steps or components or groups thereof. Therefore, the scope of the expression 'apparatus comprising devices A and B' should not be limited to an apparatus consisting of parts A and B only. This means that for the present invention, the only relevant parts of the device are A and B.

[0047] Reference throughout this specification to 'one embodiment' or 'an embodiment' means that a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com