Auxiliary Mechanism for Electric Pole Construction Used to Expand the Spacing of Overhead Conductors

A technology of overhead wires and auxiliary mechanisms, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as inconvenient operation, great safety, and potential safety hazards, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

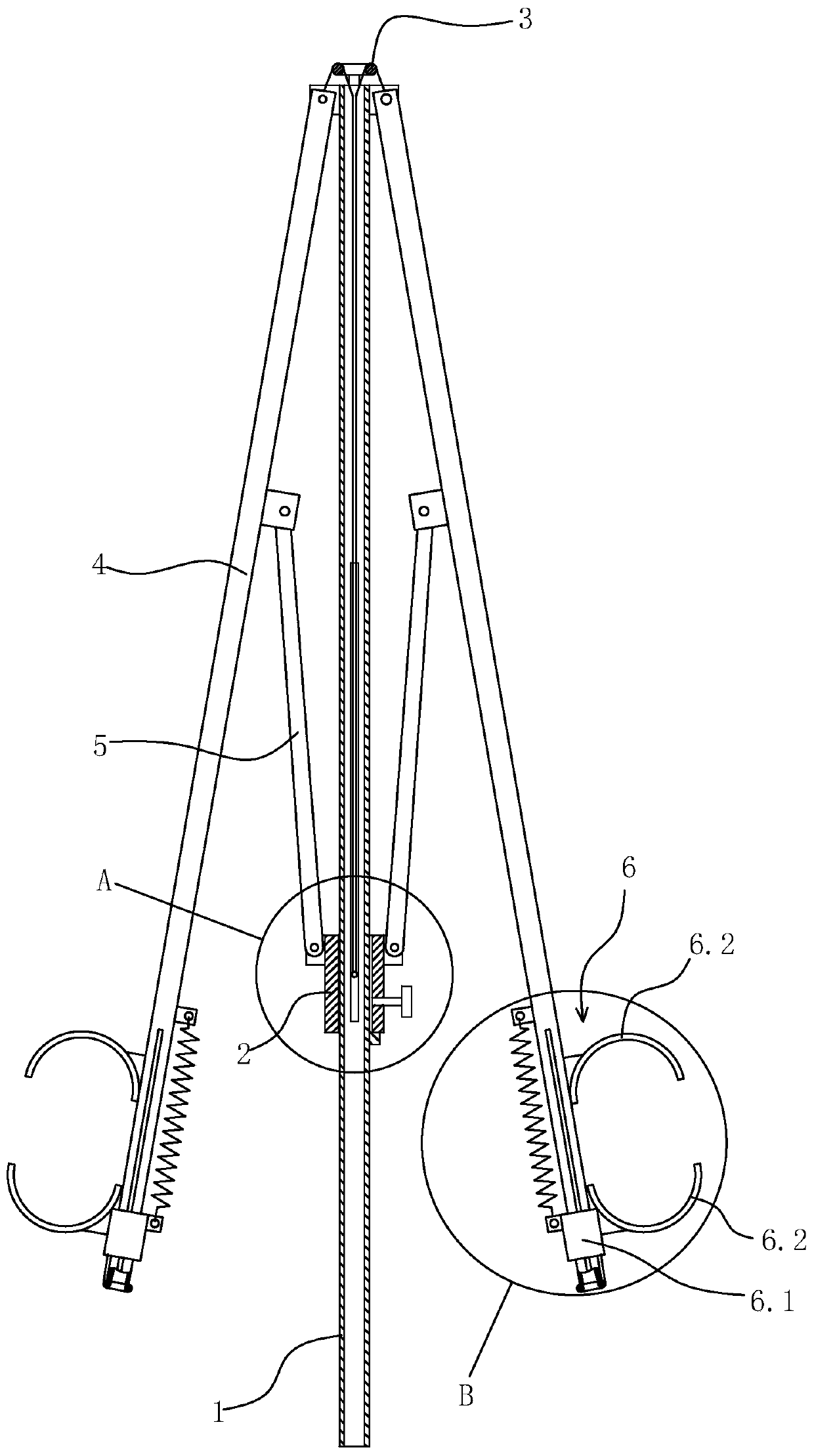

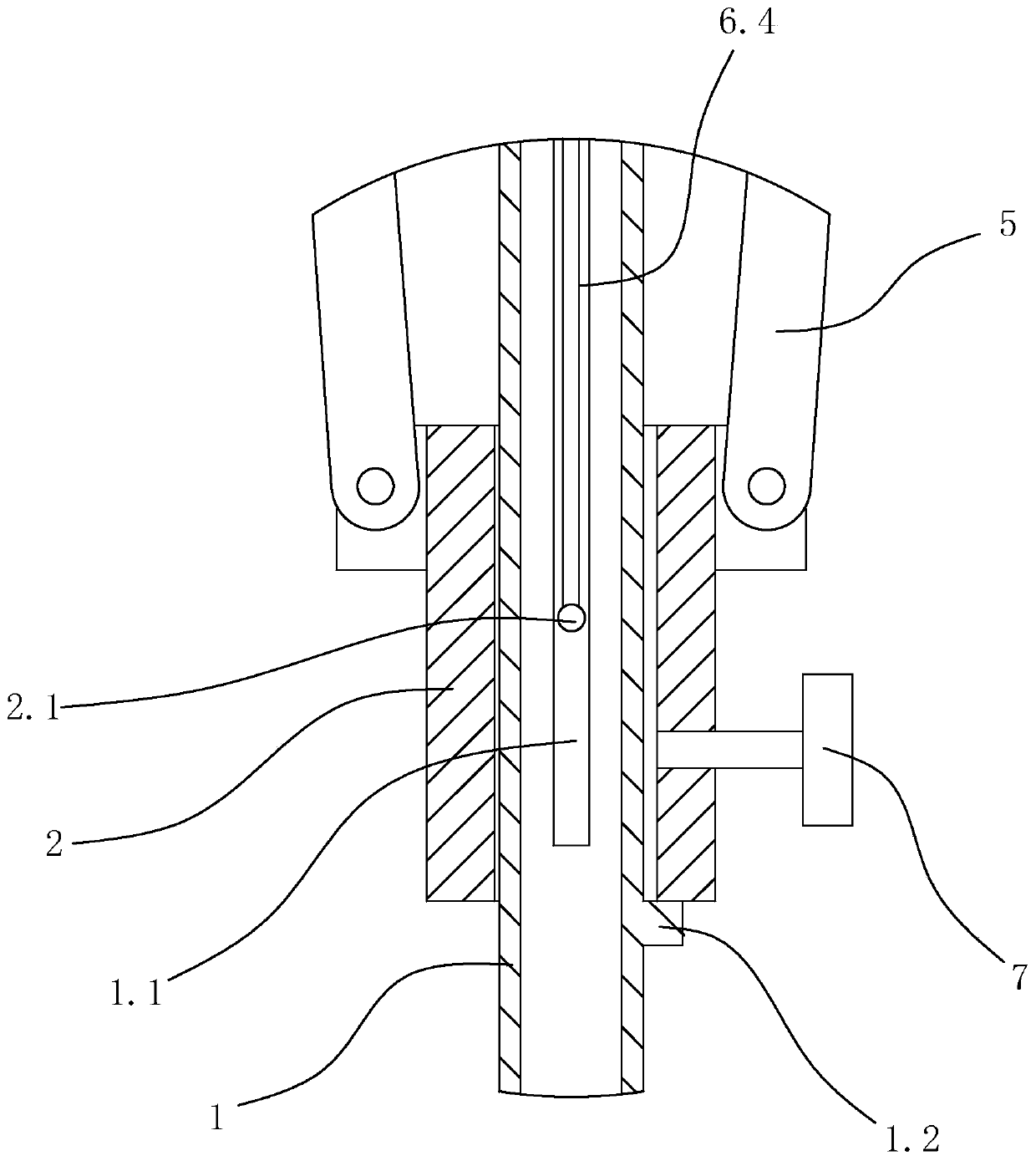

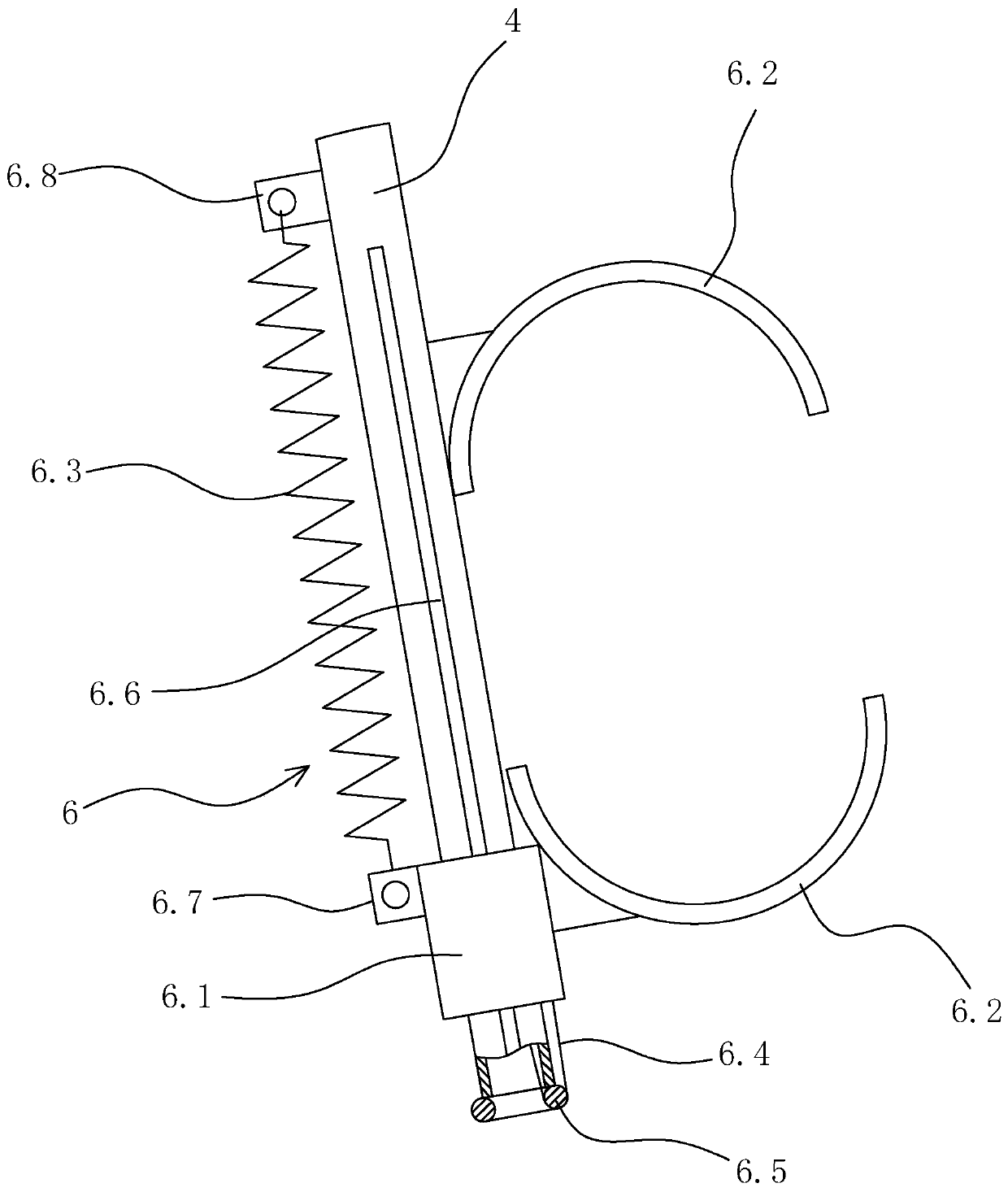

[0036] Specific embodiment one: as figure 1 , figure 2 As shown, a pole construction auxiliary mechanism for expanding the spacing of overhead wires, including a vertical riser 1, a strip-shaped hole 1.1 arranged on the pipe wall of the vertical riser and extending along the axial direction of the vertical riser , the guide ring 3 that is connected to the vertical standpipe through the connector and is located above the vertical standpipe, the sliding sleeve 2 that slides along the vertical standpipe, the sliding sleeve locking bolt 7 arranged on the sliding sleeve, and the sliding sleeve locking bolt 7 arranged on the sliding sleeve The pull rod 2.1 on the inner side of the sleeve, two tubular struts 4 distributed on the opposite sides of the vertical standpipe, and the linked wire clamping mechanism 6 arranged on the tubular struts in one-to-one correspondence.

[0037] The upper and lower ends of the vertical riser are open. The material of the vertical riser is insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com