A test platform for comprehensive mechanical properties of anchor components and anchor rods

An anchoring and assembly technology, applied in the testing of mechanical components, testing of machine/structural components, teaching models, etc., can solve problems such as complex changes in anchor mechanics, and achieve the goal of increasing design efficiency, reducing safety risks, and improving safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

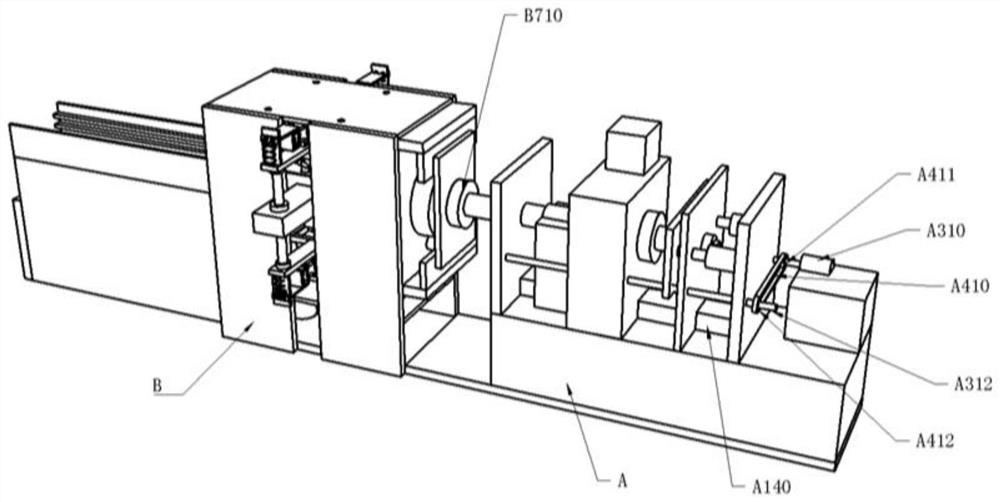

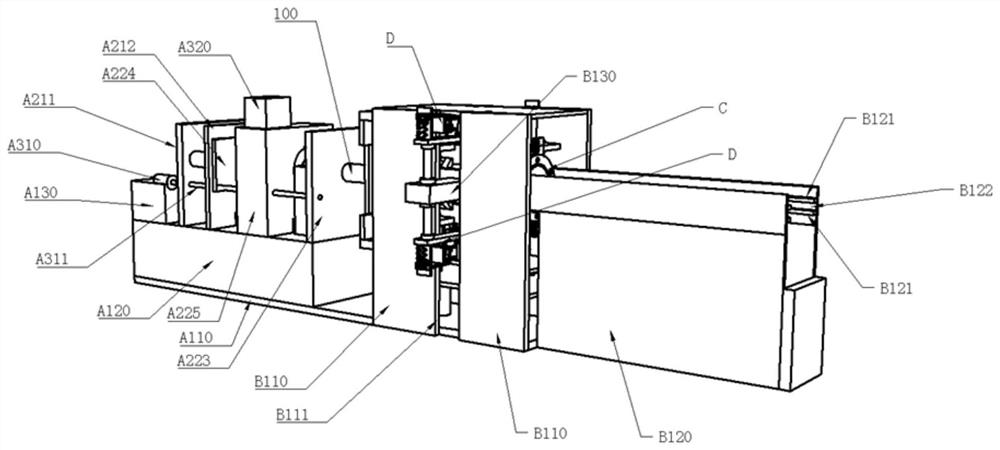

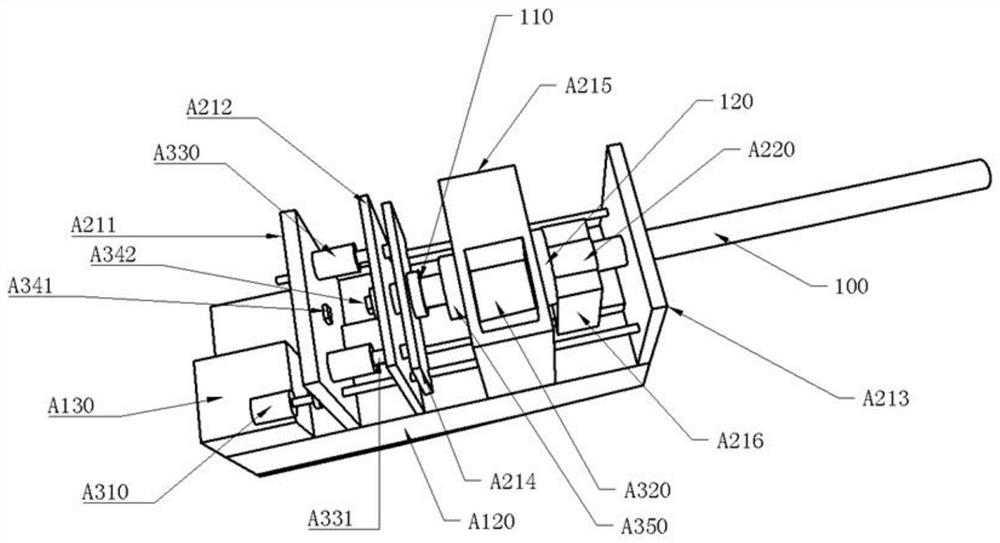

[0064] see Figure 1-Figure 25 , the test platform for the comprehensive mechanical properties of anchor rods in this embodiment includes an anchoring mechanism A and an anchoring mechanism B. The anchoring mechanism A includes an anchoring base plate A110 on which an anchoring support seat is fixed A120, the anchoring support seat A120 is fixed with an anchoring motor seat A130, an anchoring slide rail A140, a first anchoring vertical plate A211, a second anchoring vertical plate A212, and a third anchoring vertical plate A213. An anchor motor A310 is installed on the anchor motor seat A130, and the anchor slide rail A140 is slidably assembled with the anchor torque seat A215 and the anchor guide seat A216 respectively, and the output shaft of the anchor motor A310 is connected to the first drive screw rod A311 One end is connected and fixed, and the anchor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com