Treatment method for rapidly improving settling and dewatering performances of sludge

A treatment method and sludge settlement technology, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problems of limited sludge dehydration, excessive chemical dosage, and economical High cost and other issues, to achieve the effect of avoiding secondary environmental pollution, enhancing bridging effect, and improving sludge settlement performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A treatment method for rapidly improving sludge settling and dewatering performance, comprising the following steps:

[0030] (1) The remaining sludge was taken from a sewage plant in Changsha City, the moisture content of the sludge was 98.2%, and the pH of the sludge was 6.78.

[0031] (2) Adjust the pH of the sludge in step (1) from 6.78 to 6.90.

[0032] (3) At a stirring rate of 210 r / min, add cationic polyacrylamide accounting for 0.025% of the dry weight of the sludge to the sludge in step (2), and stir for 2.5 minutes to obtain mixed sludge.

[0033] (4) At a stirring rate of 210 r / min, continue stirring step (3) and mix the sludge for 2.5 minutes, then measure the dewatering performance of the sludge.

[0034] (5) Transfer the mixed sludge in step (4) to a graduated cylinder, place a magnet at the bottom of the graduated cylinder, and measure the sludge settling performance.

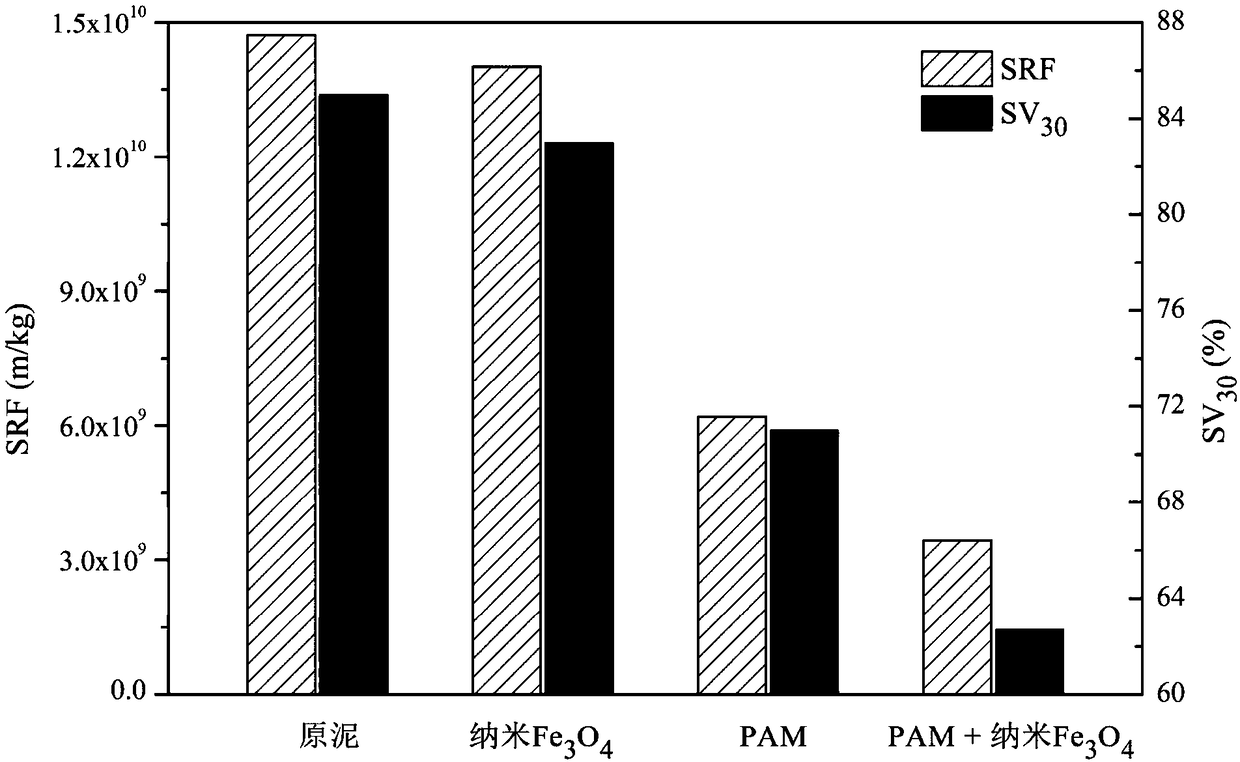

[0035] The dewatering and settling properties of the sludge before and after treatm...

Embodiment 2

[0037] A treatment method for rapidly improving sludge settling and dewatering performance, comprising the following steps:

[0038] (1) The remaining sludge was taken from a sewage plant in Changsha City, the moisture content of the sludge was 98.2%, and the pH of the sludge was 6.78.

[0039] (2) Adjust the pH of the sludge in step (1) from 6.78 to 6.90.

[0040] (3) Stir the sludge in step (1) for 2.5 min at a stirring rate of 210 r / min.

[0041] (4) under the stirring rate of 210r / min, in the sludge of step (3), continue to add and account for the nano iron ferric oxide of 1.37% of sludge dry weight, after stirring 2.5min, obtain the sludge after conditioning, measure Sludge dewatering performance.

[0042] (5) Transfer the conditioned sludge in step (4) to a graduated cylinder, place a magnet at the bottom of the graduated cylinder, and measure the sludge settling performance.

[0043] The dewatering and settling properties of the sludge before and after treatment were...

Embodiment 3

[0045] A treatment method for rapidly improving sludge settling and dewatering performance, comprising the following steps:

[0046] (1) The remaining sludge was taken from a sewage plant in Changsha City, the moisture content of the sludge was 98.2%, and the pH of the sludge was 6.78.

[0047] (2) Adjust the pH of the sludge in step (1) from 6.78 to 6.90.

[0048] (3) At a stirring rate of 210 r / min, add cationic polyacrylamide accounting for 0.025% of the dry weight of the sludge to the sludge in step (2), and stir for 2.5 minutes to obtain mixed sludge.

[0049] (4) under the stirring rate of 210r / min, in the sludge of step (3), continue to add and account for the nano iron ferric oxide of 1.37% of sludge dry weight, after stirring 2.5min, obtain the sludge after conditioning, measure Sludge dewatering performance.

[0050] (5) Transfer the conditioned sludge in step (4) to a graduated cylinder, place a magnet at the bottom of the graduated cylinder, and measure the sludg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com