Sludge treatment process

A sludge treatment and process technology, applied in the field of sludge treatment, can solve problems such as lack of water reuse, and achieve the effects of promoting rapid repair, quick results, and low treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

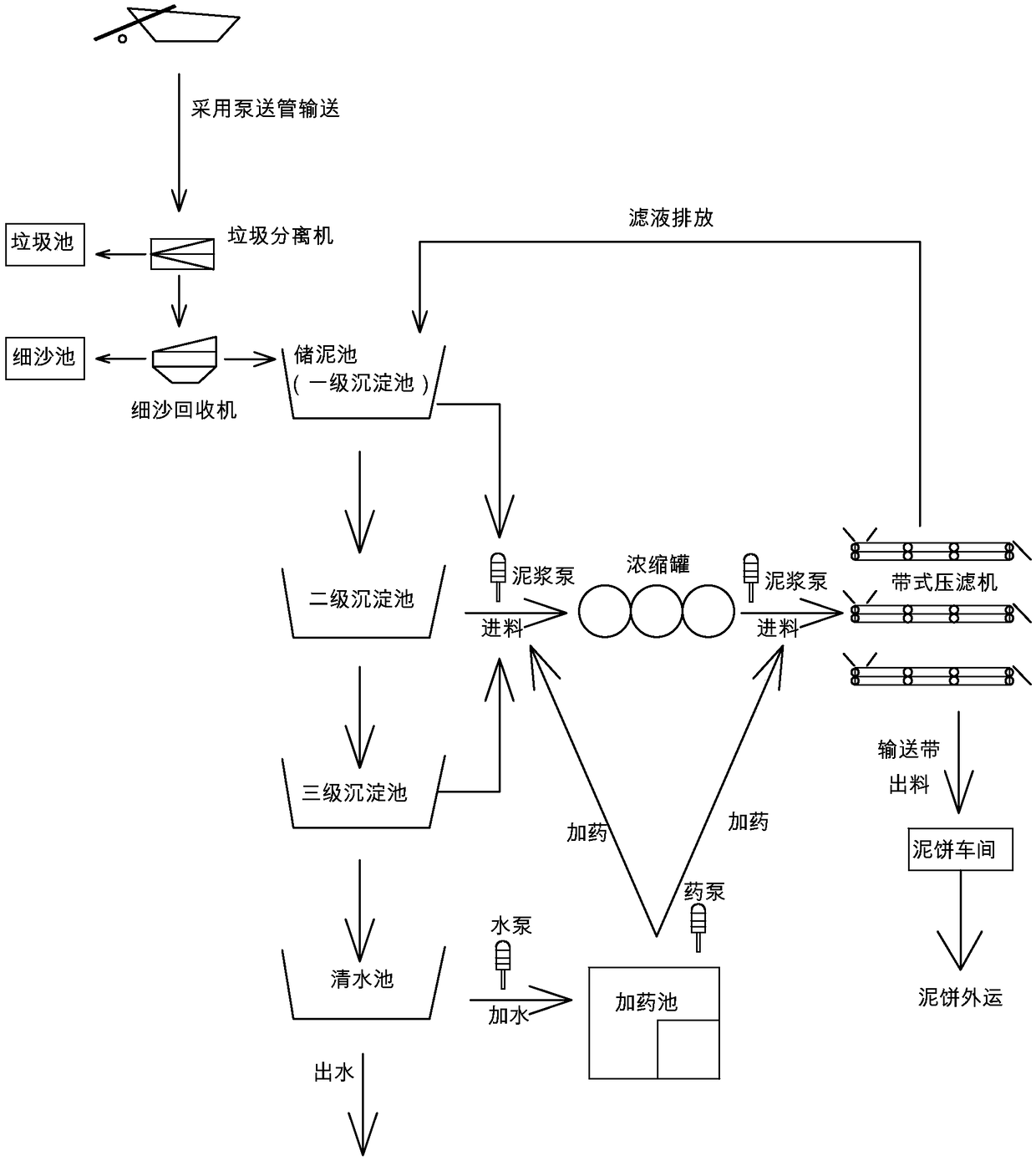

[0052] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0053] refer to figure 1 , is a kind of sludge treatment process disclosed by the present invention, comprising the following steps:

[0054] 1. A sludge treatment process, comprising the steps of:

[0055] (1) Desilting the river channel through dredging equipment and transporting through sludge pipelines;

[0056] (2) Send the sludge to the garbage sorting system for garbage sorting;

[0057] (3) The sludge is sent to the sediment separation system to remove sand and gravel in the sludge;

[0058] (4) Sludge is sent to the sludge storage tank, and a secondary sedimentation tank and a third-level sedimentation tank are set behind the sludge storage tank, and the overflow water in the third-level sedimentation tank is transported to the clean water tank;

[0059] (5) The drug dosing platform deploys the required chemicals, adds chemicals to the sludge out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com