Hole groove depth detection fixture

A depth detection and fixture technology, applied in mechanical depth measurement, manufacturing tools, workpiece clamping devices, etc., can solve the problems affecting the connection effect and strength of auto parts, high labor intensity, low detection efficiency, etc., to improve stability , Reduce the time of calibrating the workpiece position and improve the detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

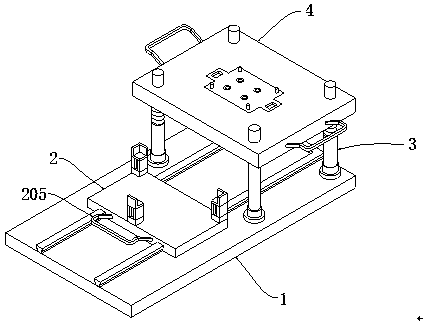

[0025] Example: such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a fixture for detecting the depth of a hole in the present invention includes a base 1 on which a moving mechanism 2, a supporting mechanism 3 and a detecting mechanism 4 are arranged; the moving mechanism 2 includes a guide rail 201, a moving plate 202, a support block 203, a clamp Holding block 204 and handrail 205, guide rail 201 is arranged on the surface of base 1, moving plate 202 is arranged on the guide rail 201, support block 203 and handrail 205 are arranged on the moving plate 202, clamping block 204 is arranged on the support block 203, by The moving plate 202 and the guide rail 201 in the moving mechanism 2 can facilitate the staff to move the parts to be tested to the station to be tested, which improves the staff's detection efficiency and reduces the time for the staff to calibrate the position of the workpiece. Through the support block 203 and The clamping block 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com