Intelligent torque operation supervision system and control method

A monitoring system and intelligent technology, applied in the fields of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of inability to effectively control the bolt tightening sequence and operation process, the inability to effectively control the tightening process, and the collection and recording of torque values. , to achieve the effect of improving the quality of tightening operations, eliminating potential safety hazards and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

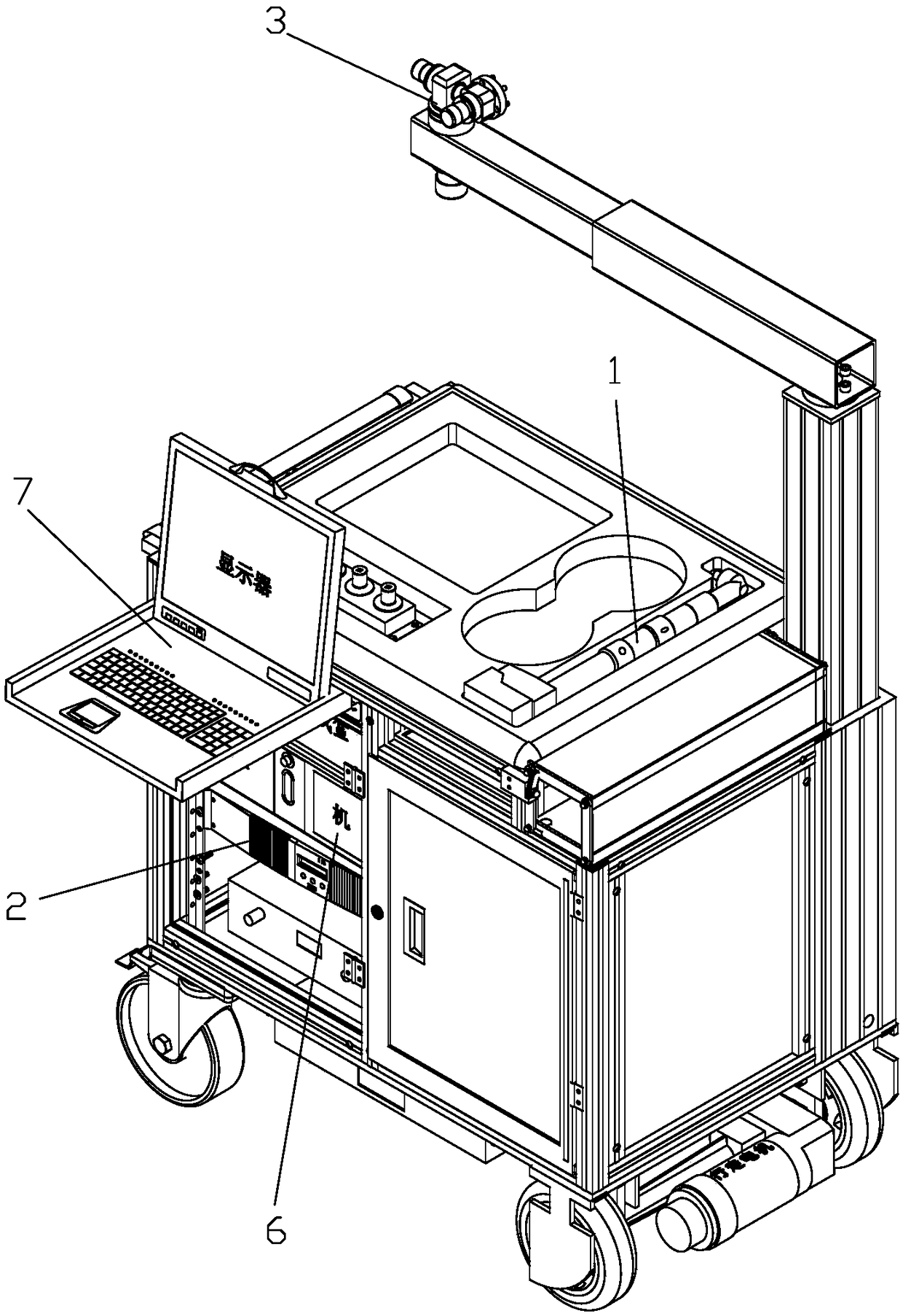

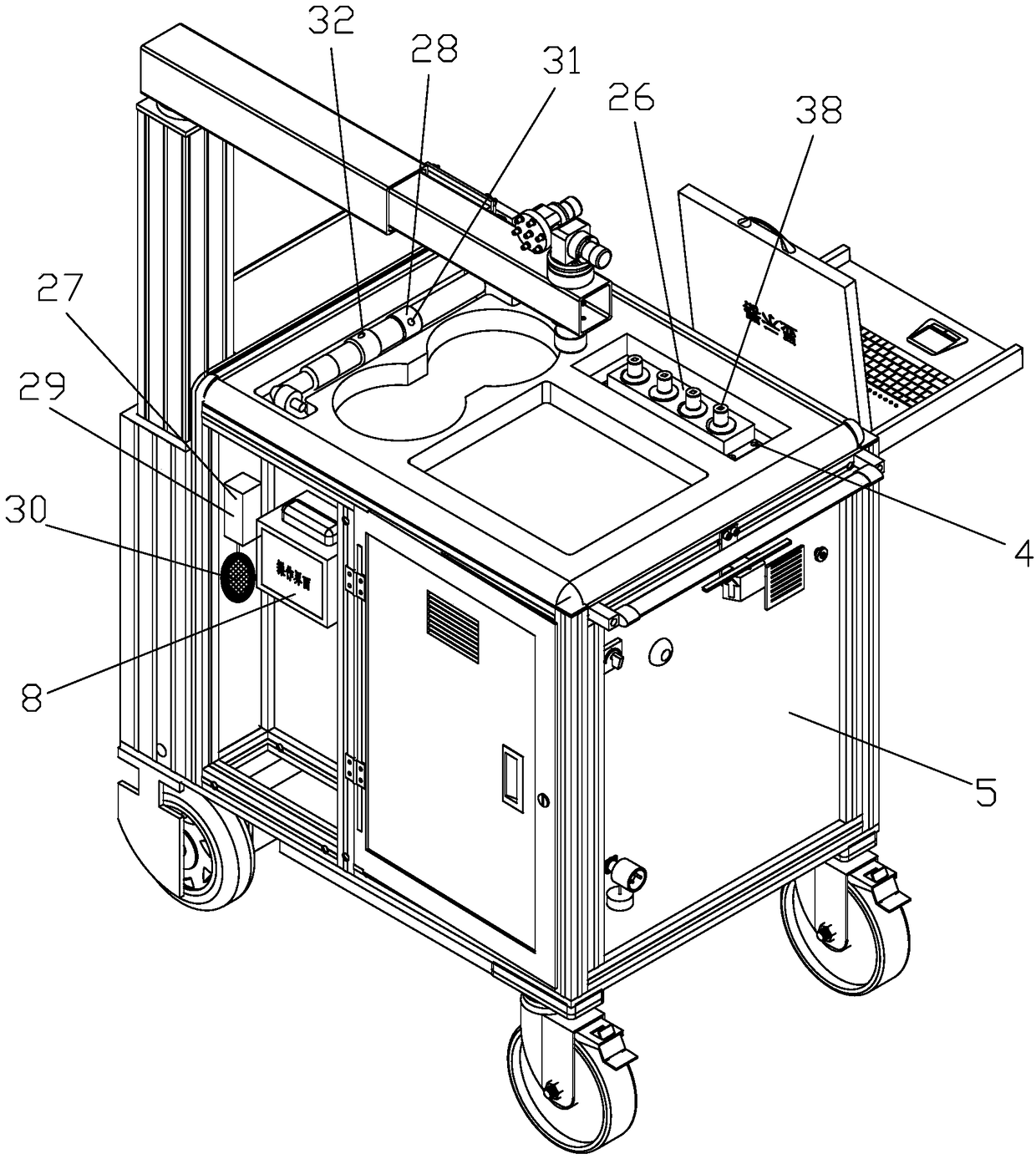

[0035] An intelligent torque operation supervision system provided by this embodiment has a structure such as Figure 1-2 As shown, it includes an intelligent electric torque wrench 1, a control system 2, a laser calibration inspection system 3 and an error prevention system 4, and the laser calibration inspection system 3 is connected to the control system 2.

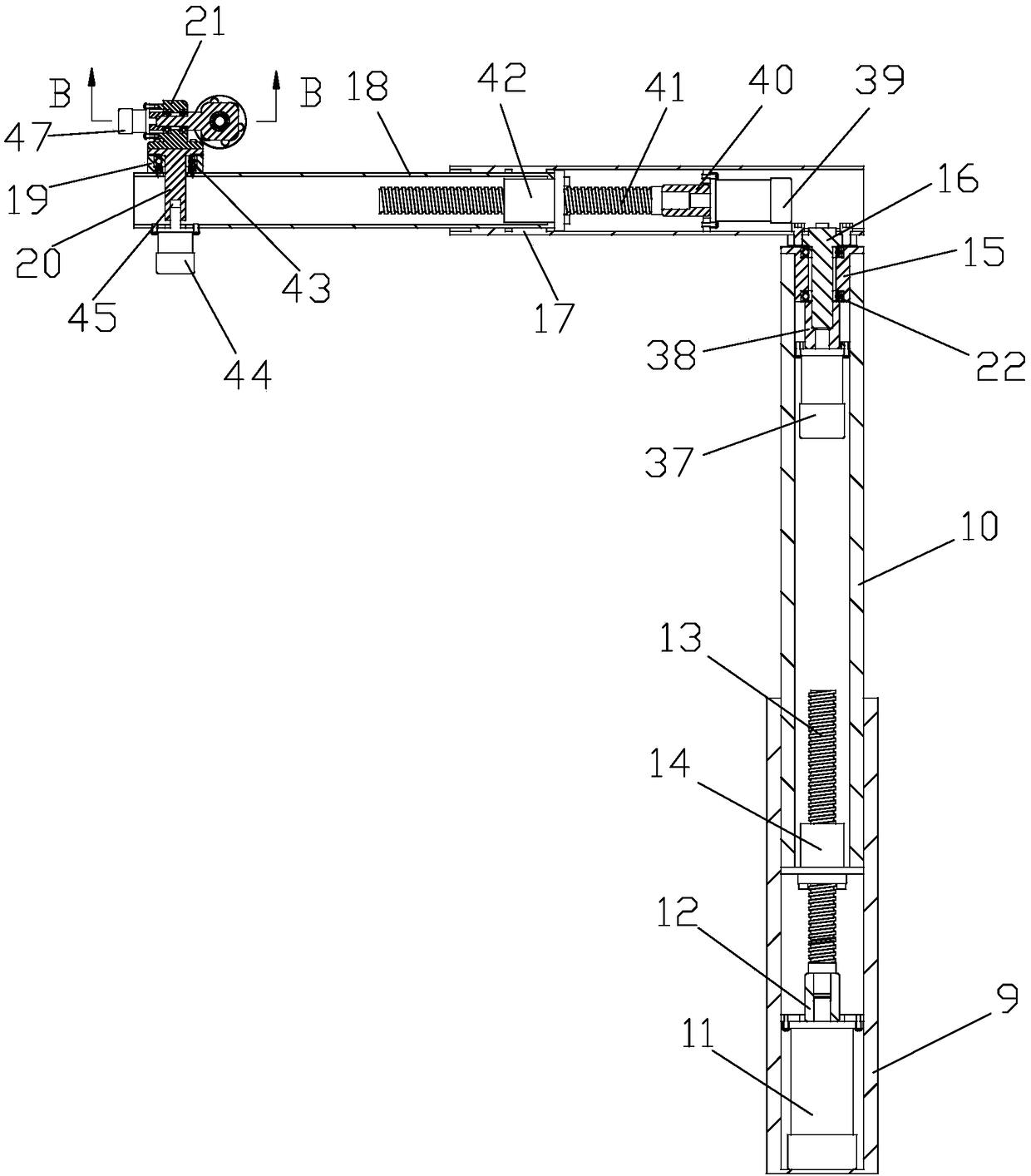

[0036] like Figure 3-4As shown, the laser calibration inspection system 3 includes an upper column 10 , a lower column 9 , a front mechanical arm 18 and a rear mechanical arm 17 . The lower column 9 is sleeved outside the upper column 10, and the lower column 9 is provided with an adjusting device one, and the adjusting device one makes the upper column 10 slide up and down in the lower column 9. The rear mechanical arm 17 rear end is vertically installed on the upper column 10 top, and the upper column 10 is provided with adjustment device two, and the adjustment device two makes the rear mechanical arm 17 can rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com