Rubber vulcanization waste gas collecting device

A gas collecting device and rubber vulcanization technology, which is applied in chemical instruments and methods, smoke removal, cleaning methods and utensils, etc., can solve the problems of many exhaust gas points, pollution, complex and changeable pollution components, etc., and achieves convenient and difficult installation process. impacted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific technical solutions of the present invention are described in conjunction with the accompanying drawings.

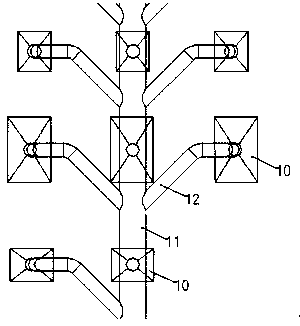

[0013] Such as figure 1 As shown, the rubber vulcanization exhaust gas collection device includes a main pipeline 11, the main pipeline 11 is connected to the exhaust gas treatment device through a fan, and a plurality of sub-pipes 12 are connected to the main pipeline 11, and the main pipeline 11 and the sub-pipes 12 are respectively Connect the vertical pipe 1, and the vertical pipe 1 is connected to the gas collection hood 10 through the connection system; the gas collection hood 10 is opened downward and is located on the exhaust gas discharge source; The gas source is set, that is, it is designed according to the plane layout of the vulcanization equipment.

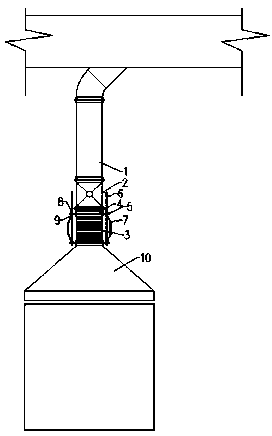

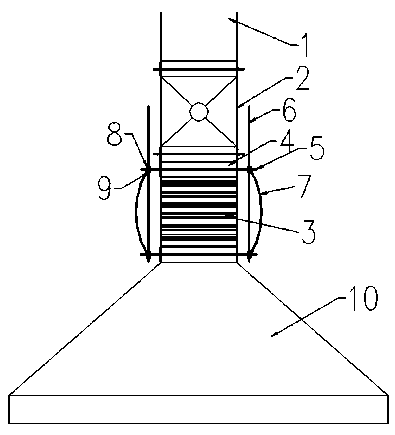

[0014] Such as figure 2 and image 3 As shown, the connection system includes a variable diameter pipe joint 2 and a telescopic pipe 3, the upper end of the variable diameter pipe joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com