Special-shaped flat aluminum alloy conductor cable for new energy automobile

A technology for new energy vehicles and aluminum alloy conductors, applied in the direction of metal/alloy conductors, flat/ribbon cables, conductors, etc., can solve the problems of difficult layout and other problems, and achieve improved life, excellent tensile strength, and good economy performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

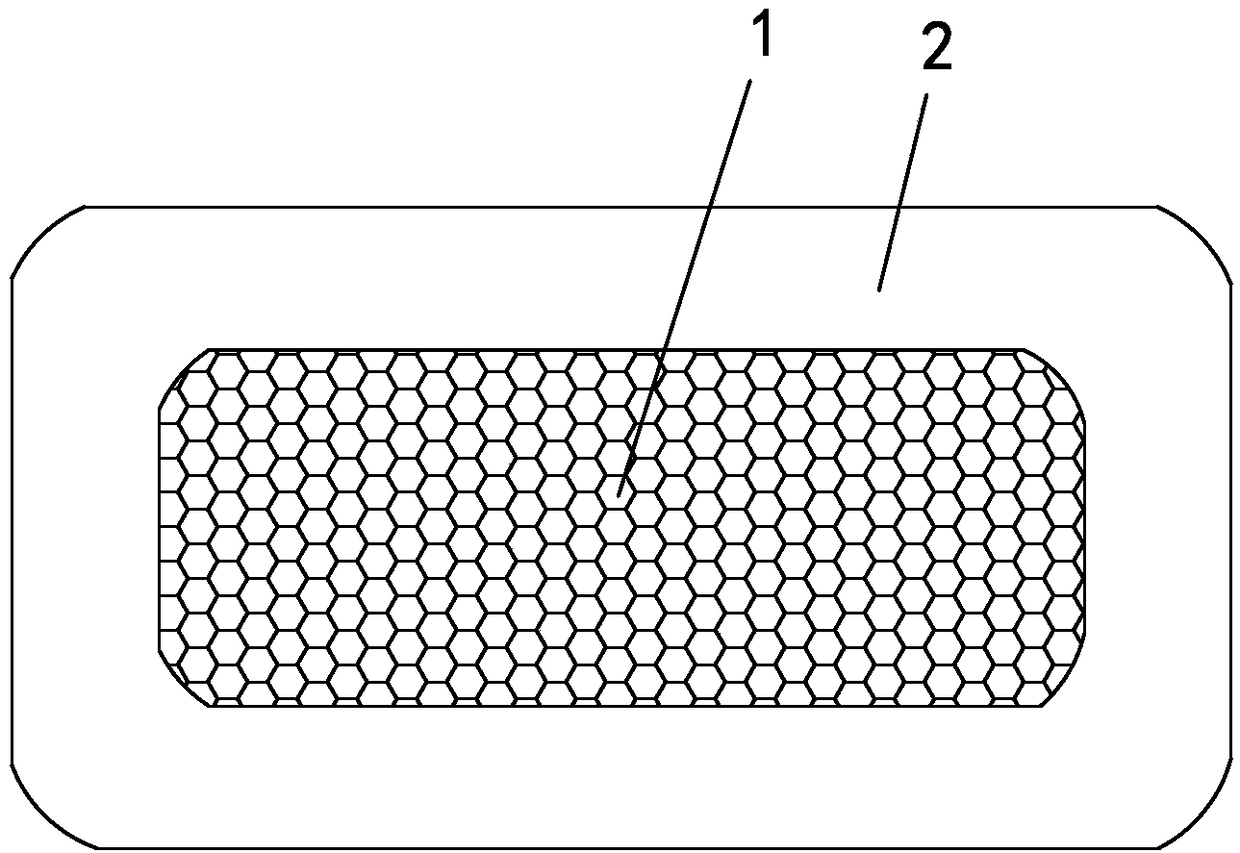

[0076] Example: such as figure 1 As shown, a special-shaped flat aluminum alloy conductor cable for new energy vehicles includes a central conductor 1 and a cross-linked TPE insulation layer 2; the central conductor 1 is a flat conductor made by annealed aluminum alloy; the cross-linked TPE The insulating layer 2 tightly covers the outer periphery of the central conductor 1 .

[0077] The raw material of the aluminum alloy includes the following components in parts by weight:

[0078] Aluminum 25~35 parts;

[0079] Iron 0.4~0.6 part;

[0080] Silicon 0.06~0.08 parts;

[0081] Copper 0.15~0.3 part;

[0082] Magnesium 0.02~0.05 parts;

[0083] Impurities are less than 0.3 parts;

[0084] By controlling the component content of copper element, magnesium element and impurities, on the one hand, it can ensure good creep resistance of the finished conductor, and at the same time, it can ensure better product strength and elongation.

[0085] The crosslinked TPE insulation lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com