An excitation layout optimization method for improving plasma excitation flow control efficiency

A plasma and flow control technology, applied in the field of plasma, can solve the problems that flow control measures are difficult to be applied in practical engineering and difficult to effectively suppress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

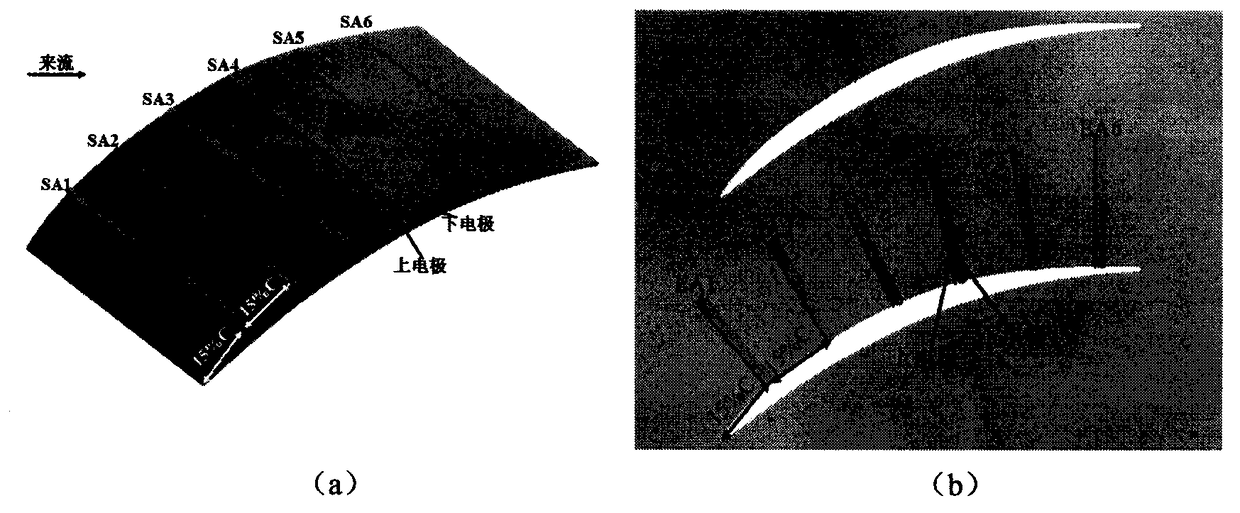

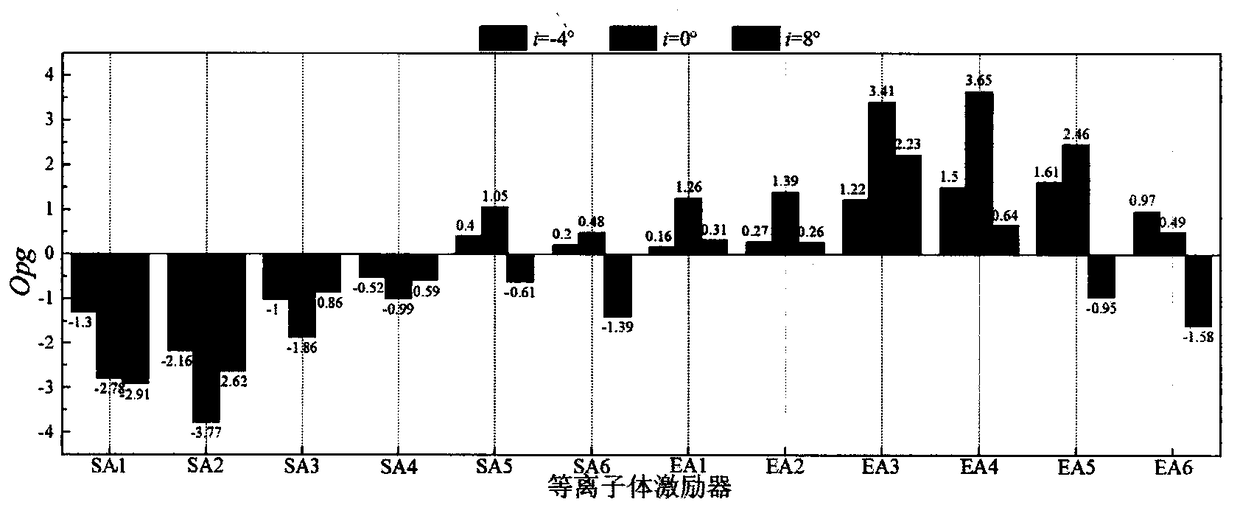

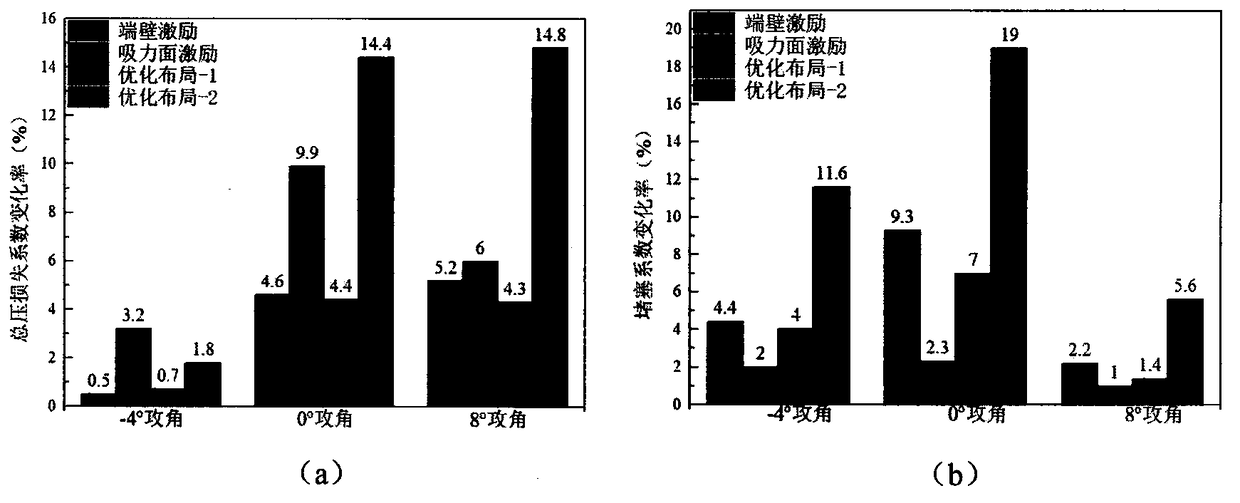

[0050] The present invention is developed for a high-speed compressor cascade model. The high-speed compressor cascade model is NACA65-K48 high-speed compressor cascade, and its main aerodynamic parameters are shown in the table below. The numerical simulation calculation adopts Ansys CFX commercial fluid software, and uses the RANS method to carry out unsteady numerical simulation. The grid topology in the numerical simulation method is H-O-H. In order to more accurately simulate the influence of plasma excitation on the flow field of the high-speed compressor cascade, the numerical simulation grid is figure 1 The position of the plasma exciter in the center is locally refined, and the final total number of grids is 2.8 million. The selected turbulence model is still the k-ω eddy viscosity model. The body force induced by plasma excit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com