Small raw silk fineness inspection device for silk reeling enterprises

A raw silk, small-scale technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of unsuitable raw silk fineness detection requirements for reeled silk, large space occupied by the device, high raw silk length error, etc., to achieve flexible silk length and space occupation The effect of small and small length error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

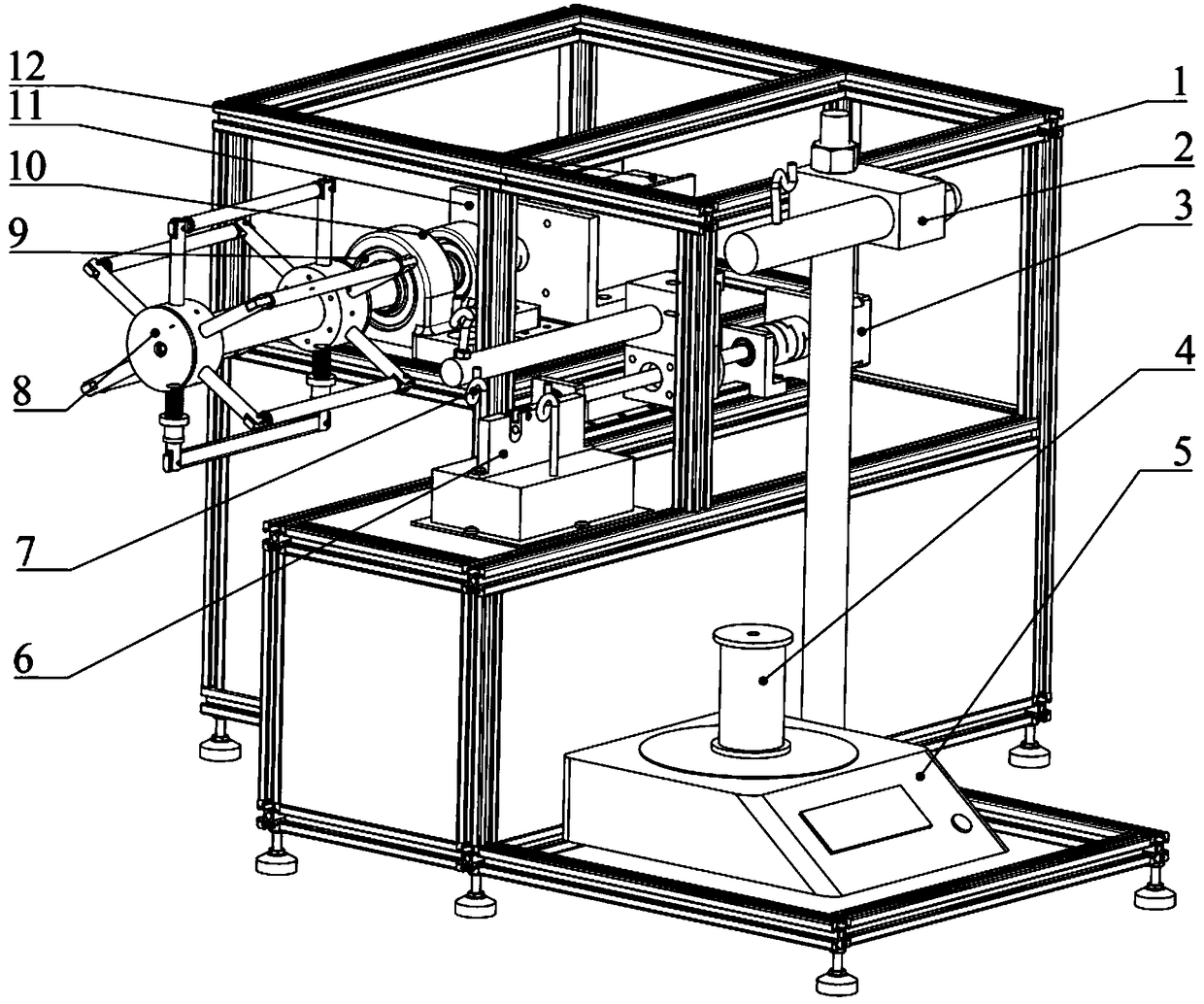

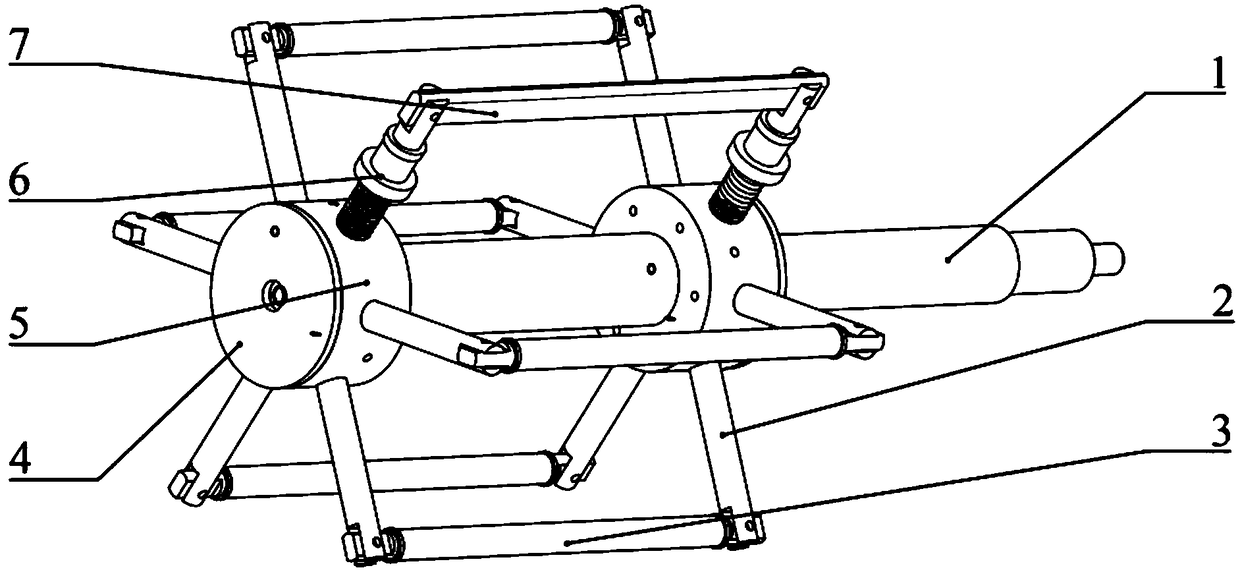

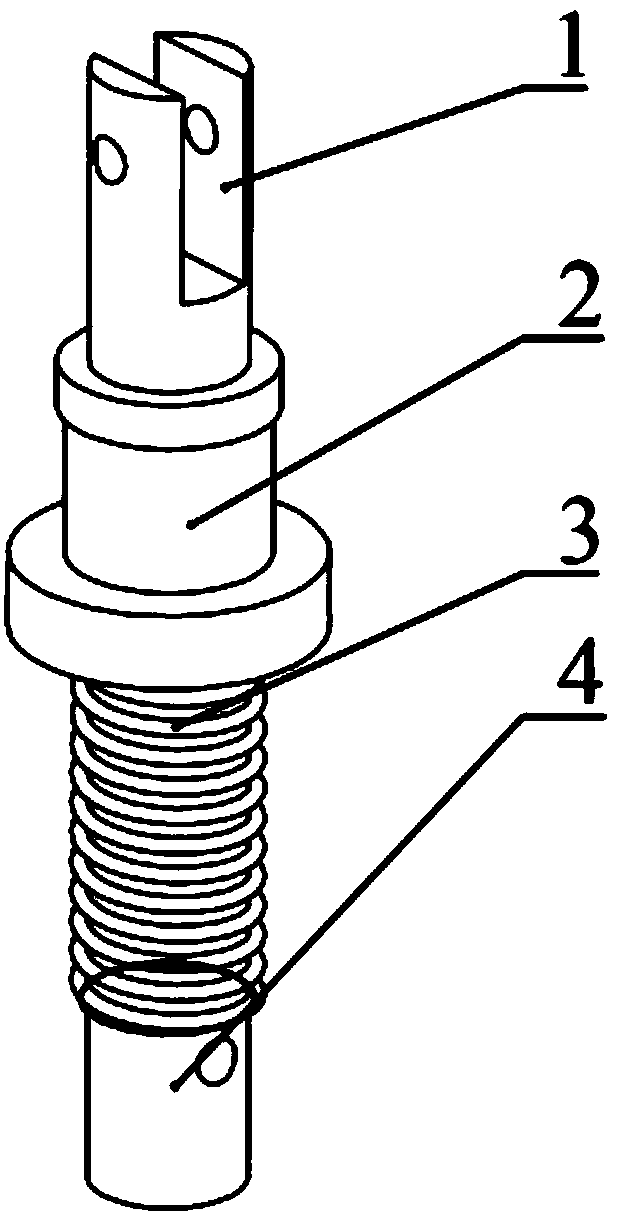

[0017] The present invention will be described in detail below in conjunction with accompanying drawing, and the overall structure schematic diagram of described a kind of small-scale raw silk fineness inspection device for silk reeling enterprise is as follows figure 1 As shown, it includes frame 1, adjustable bracket 2, ball screw slide table 3, wire spindle 4, high-precision electronic balance 5, broken wire detection sensor 6, guide wire hook 7, winding mechanism 8, bearing 9, bearing Seat 10, servo motor support 11, AC servo motor 12. The fixed-length wire-taking module includes a coiling mechanism 8 , two bearing seats 10 and corresponding bearings 9 , an AC servo motor 12 , and a servo motor bracket 11 . The transmission shaft of the winding mechanism 8 adopts the fixing mode of the cantilever beam, the transmission shaft of the winding mechanism 8 is in interference fit with two bearings 10, the bearing 9 is fixed on the frame 1 by the bearing block 10, and the winding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com