Bearing testing machine

A bearing test and bearing technology, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problem of being unable to objectively and truly detect bearing performance and life, and unable to simulate two sets of test bearings in the axial direction. The load is different, and the problems such as bearings cannot be simulated more realistically, so as to achieve the effect of objective real performance and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

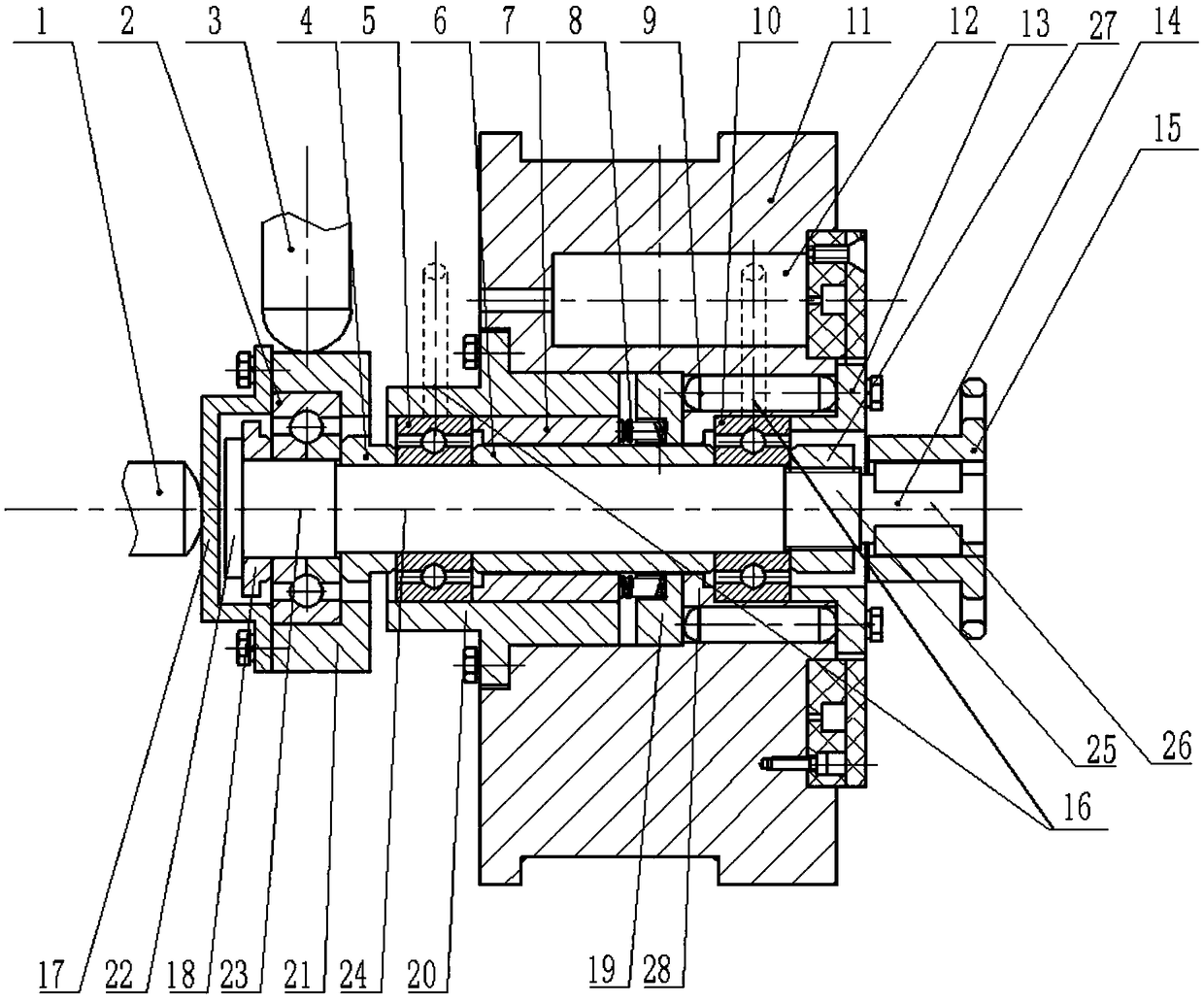

Image

Examples

Embodiment 2

[0027] Embodiment 2 of the present invention: the difference between this embodiment and embodiment 1 is that the elastic member that exerts the first forward axial loading force on the axial loading ring can be replaced by a gas spring.

Embodiment 3

[0028] Embodiment 3 of the present invention: The difference between this embodiment and Embodiment 1 is that the main shaft 14 may not be set as a five-stage stepped shaft, but may be set as two or three or four stages, or may be set as a front and rear diameter Consistent round shafts are also available.

Embodiment 4

[0029] Embodiment 4 of the present invention: The difference between this embodiment and Embodiment 1 is that the loading spring adjusting rod 9 can also be set as a telescopic rod with adjustable length, so that there is no need to replace the loading spring adjusting rods of different lengths, only need Just adjust the length of the loading spring adjusting rod 9 and get final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com