Five-axis rotary data calibration ball and using method thereof

A technology for calibrating balls and data, applied in the direction of mechanical devices, measuring devices, instruments, etc., can solve problems such as unfavorable popularization, inconsistent standards, and cumbersome operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the present invention, the following will clearly and completely describe the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only a part of the present invention, rather than Full examples.

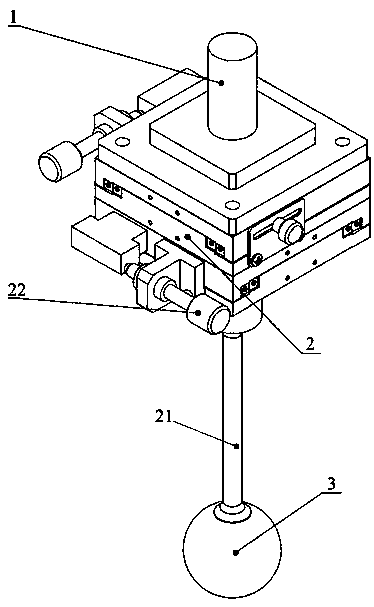

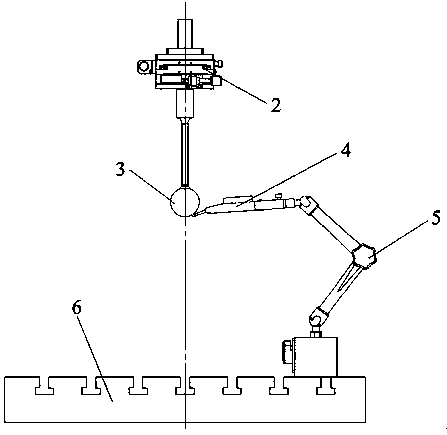

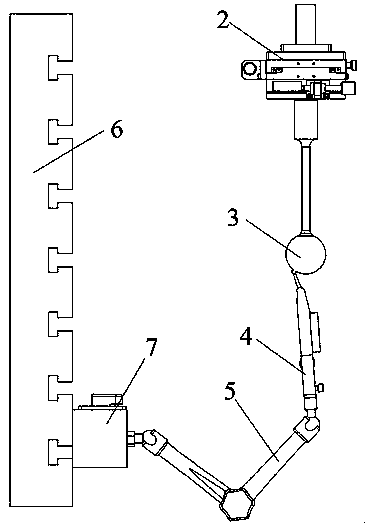

[0032] The embodiment of the present invention discloses a five-axis rotary data calibration ball, such as figure 1 As shown, it includes a clamping part 1, a fine-tuning slide 2, and a calibration ball 3. The clamping part 1 is installed on the upper end of the fine-tuning slide 2, and a fixing rod 21 is arranged under the fine-tuning slide 2, and the fine-tuning slide 2 passes through the fixed rod. 21 links to each other with calibration ball 3, makes calibration ball 3 be installed in fine-tuning slide table 2 lower ends.

[0033] Optionally, the fine-tuning slide 2 is a cross fine-tuning slide 2 .

[0034] Optionally, the calibration ball 3 is a bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com