A variable cross-section lobe ejector mixer suitable for pulse detonation engines

A pulse detonation and mixer technology, which is applied to machines/engines, rocket engine devices, mechanical equipment, etc., can solve the problems of high under-expansion and no longer applicable, and can increase the ejection amount, facilitate industrial production, and improve the The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Now in conjunction with specific embodiment, accompanying drawing, the present invention will be further described:

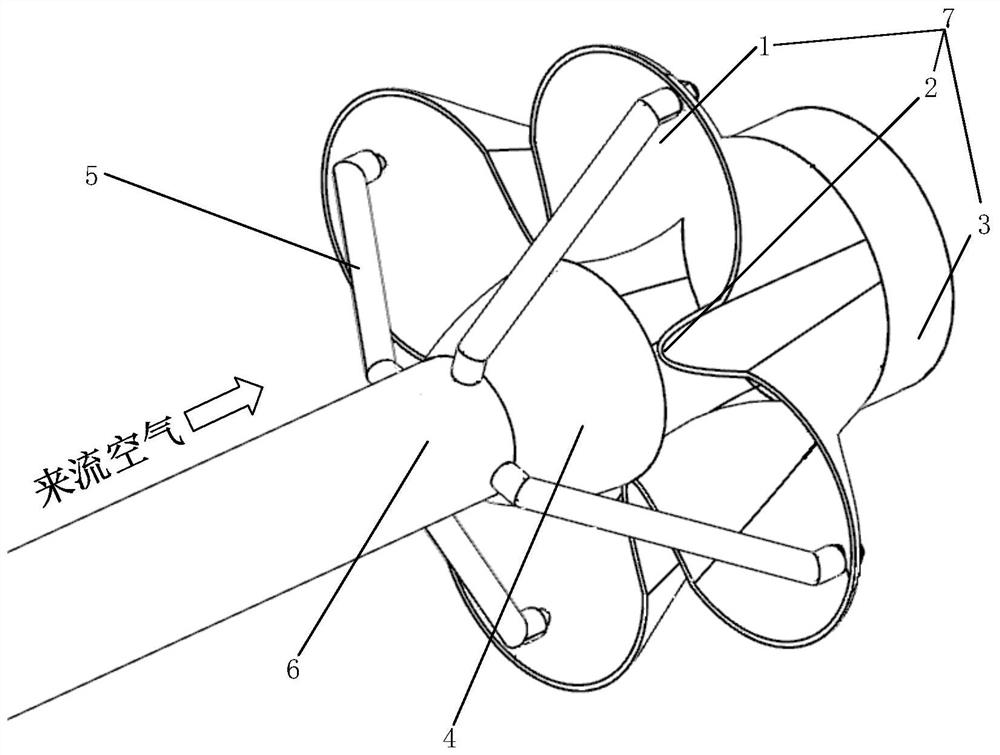

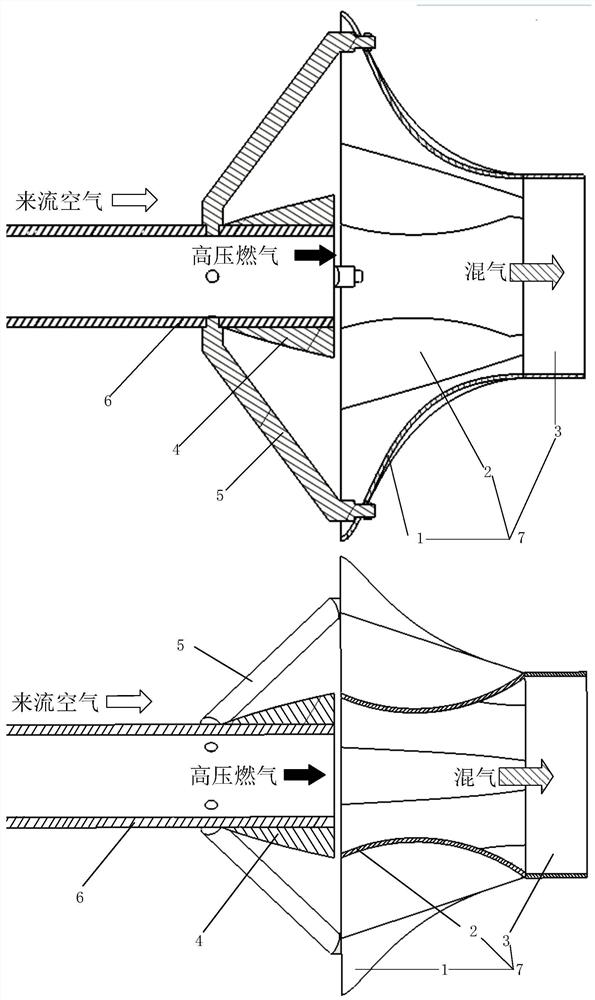

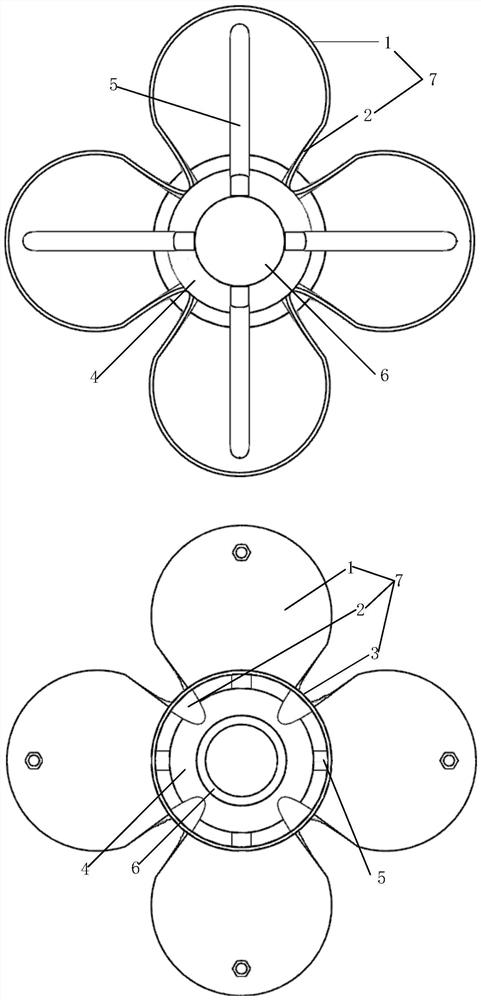

[0024] to combine Figure 1~3 , the present invention proposes a variable section lobe ejector mixer suitable for pulse detonation engines. figure 1 It is a schematic structural diagram of a variable-section petal-shaped ejector mixer for a pulse detonation engine. The variable-section petal-shaped ejector mixer part includes an outer convex part of the ejector mixer (1) and an inner concave part of the ejector mixer (2) , the straight pipe section of the injector mixer (3), the conical annular baffle (4), the strut (5), the detonation tube (6), and the injector composed of parts (1) to (3) mixer body (7), figure 2 is the sectional view of the variable-section petal ejector mixer, image 3 Front view and rear view of variable section petal ejector mixer.

[0025] according to figure 1 As shown, the convex lobe part (1) of the injection mixer and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com