Polyurethane catalyst and preparation method thereof, polyurethane spraying hard foam, and polyurethane soft foam

A polyurethane catalyst, rigid foam technology, applied in the direction of polyurea/polyurethane coatings, coatings, fire-resistant coatings, etc., can solve the problems of by-product heteropoly, poor reaction selectivity, low yield, etc., to reduce odor and selectivity High and low emission effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

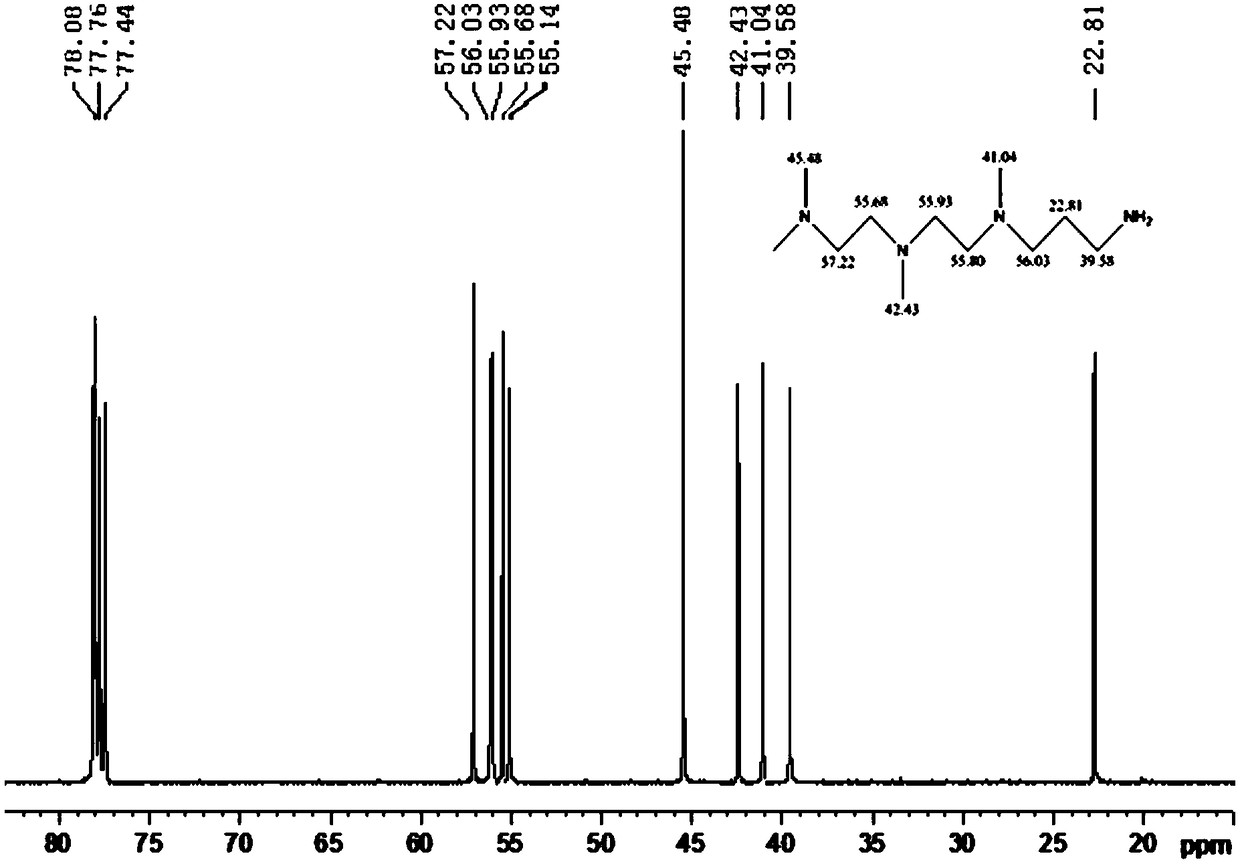

[0078] N,N,N’,N”-tetramethyl-N”-3-aminopropyldiethylenetriamine:

[0079] 500g (3.42mol) N,N,N'-trimethyl-N'-hydroxyethylethylenediamine and 40gCu / ZnO / Al 2 o 3 (JL-2 of Suzhou Jinlong Catalyst Co., Ltd.) was added to a 2L stainless steel autoclave. After purging the reactor with nitrogen and hydrogen, the catalyst was reduced at 195°C for 10 hours under a hydrogen pressure of 5.6 MPa, then the reactor was cooled to 25°C and vented to ambient pressure. Then 180 g (5.80 mol) of monomethylamine were added. After pressurizing to 1.5MPa with hydrogen, the reactor was heated to 200°C, reacted for 24 hours and cooled to 25°C, and the catalyst particles were filtered off to recover the product. Distill the reaction product to obtain N,N,N'-trimethyl-N'-hydroxyethylethylenediamine, N,N,N',N"-tetramethyldiethylenetriamine and other amines mixture.

[0080] Put 300g (containing about 1.20mol of N,N,N',N"-tetramethyldiethylenetriamine) of the above distillate into a three-necked roun...

Embodiment 2

[0088] In the following B3 formula system for exterior wall spraying (B3 classification of high-rise building decoration materials for combustion performance, the fire rating of polyurethane materials added with flame retardants in this formula is B3), the N, N, N', N"-tetramethyl -N"-3-aminopropyldiethylenetriamine and bis(tetramethyldiethylenetriaminopropyl)amine for application evaluation. The mixing mass ratio of the catalyst composition is N,N,N',N"-tetramethyl-N"-3-aminopropyldiethylenetriamine:bis(tetramethyldiethylenetriaminopropyl base) amine=8:2. The formulation composition is shown in Table 2.

[0089] Table 2 Composition of Embodiment 2

[0090]

[0091]

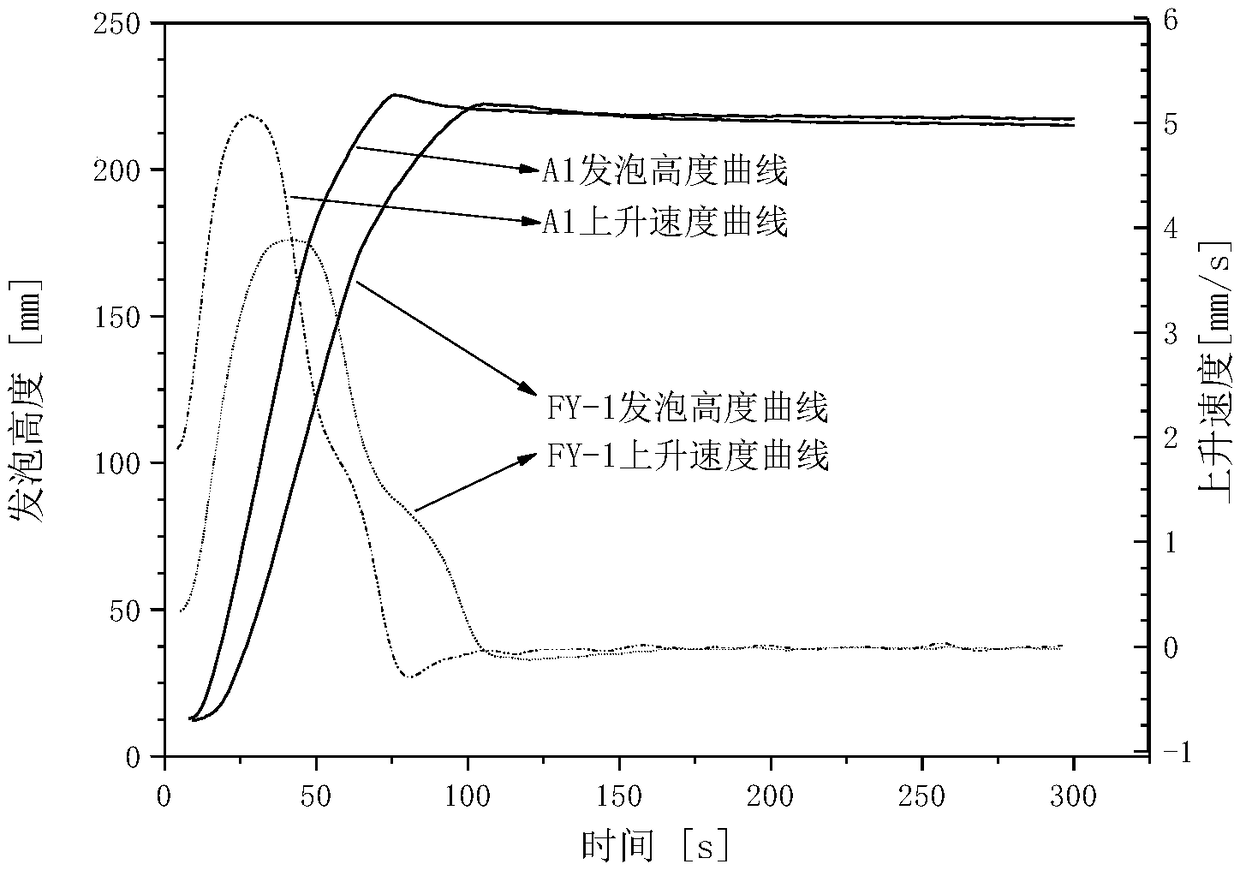

[0092] Configure the combined material according to the above formula, and use one-step method for manual free foaming operation: add the components of the prepared combined material into the container for high-speed dispersion for 5 minutes to obtain the combined material; put the combined material and P...

Embodiment 3

[0097] 50Kg / m 3 In the left and right modified MDI-based automotive high-resilience seat systems, the foaming performance of bis(tetramethyldiethylenetriaminopropyl)amine was tested.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com