A kind of preparation method of powdery carboxylic acid water reducing agent

A water-reducing agent and powdery technology, which is applied in the field of preparation of powdered polycarboxylate water-reducing agent, can solve the problems of reduced performance of polycarboxylate water-reducing agent, high viscosity of the reaction system, and explosive polymerization, and achieves an increase in the amount of pure pulp. Fluidity, increase dispersion, avoid the effect of bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

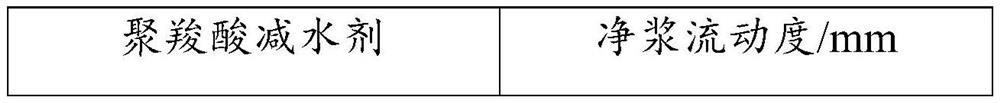

Examples

Embodiment 1

[0040] This embodiment provides a preparation method of powdery polycarboxylate water reducer, which specifically includes the following steps:

[0041](1) drop into the isobutylene alcohol polyoxyethylene ether (SPEG, molecular weight: 2400) of 1 mass part in the reactor, the deionized water of 0.01 mass part, replace the air in the reactor with nitrogen; Raise the temperature in the reactor, make The temperature of the kettle rises to 55°C to melt isobutylene alcohol polyoxyethylene ether;

[0042] (2) Add 0.5 parts by mass of cumene hydroperoxide to the melted isobutylene alcohol polyoxyethylene ether, then raise the temperature in the reactor to 115°C, then start to drop 0.05 parts by mass of acrylic acid and 0.1 parts by mass of Mixture of mercaptopropionic acid;

[0043] (3) Control the temperature in the reactor to be 115-120°C, and the pressure in the reactor to be less than 0.1MPa. Add the mixture of acrylic acid and mercaptopropionic acid dropwise within 2 hours; A...

Embodiment 2

[0046] This embodiment provides a preparation method of powdery polycarboxylate water reducer, which specifically includes the following steps:

[0047] (1) Add 0.3 parts by mass of methallyl polyoxyethylene ether (TPEG, molecular weight: 2400), 0.7 parts by mass of isobutylene alcohol polyoxyethylene ether (SPEG, molecular weight: 2400), 0.008 parts by mass deionized water, and replace the air in the reactor with nitrogen; increase the temperature in the reactor to make the temperature of the reactor rise to 45°C, and melt the methallyl polyoxyethylene ether and the isobutylene alcohol polyoxyethylene ether;

[0048] (2) Add 0.65 parts by mass of dicumyl peroxide to the molten methallyl polyoxyethylene ether and isobutenyl alcohol polyoxyethylene ether, then raise the temperature in the reactor to 80°C, and then start to drop The mixed solution of the methacrylic acid of 0.1 mass part and the mercaptoacetic acid of 0.15 mass part;

[0049] (3) Control the temperature in the ...

Embodiment 3

[0052] This embodiment provides a preparation method of powdery polycarboxylate water reducer, which specifically includes the following steps:

[0053] (1) drop into the allyl alcohol polyoxyethylene ether (APEG, molecular weight: 3000) of 1 mass part in the reactor, the deionized water of 0.012 mass part, replace the air in the reactor with nitrogen; Raise the temperature in the reactor, Raise the kettle temperature to 55°C to melt allyl alcohol polyoxyethylene ether;

[0054] (2) Add 0.45 parts by mass of lauryl peroxide to the molten allyl alcohol polyoxyethylene ether, then raise the temperature in the reactor to 70°C, then start to drop 0.15 parts by mass of maleic anhydride and 0.11 parts by mass The mixed solution of the mercaptopropionic acid of one part;

[0055] (3) Control the temperature in the reactor to 70-75°C, and the pressure in the reactor to <0.1MPa, and drop the mixture of maleic anhydride and mercaptopropionic acid within 2 hours; Lower heat preservatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com