A kind of ampoule bottle printing device and using method thereof

An ampoule bottle and printing technology, which is applied to general parts of printing machinery, printing, printing machines, etc., can solve the problems of being easily scratched, stained with dust, unclear fonts, and unclear printing, etc. Printing processing efficiency, the effect of easy promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

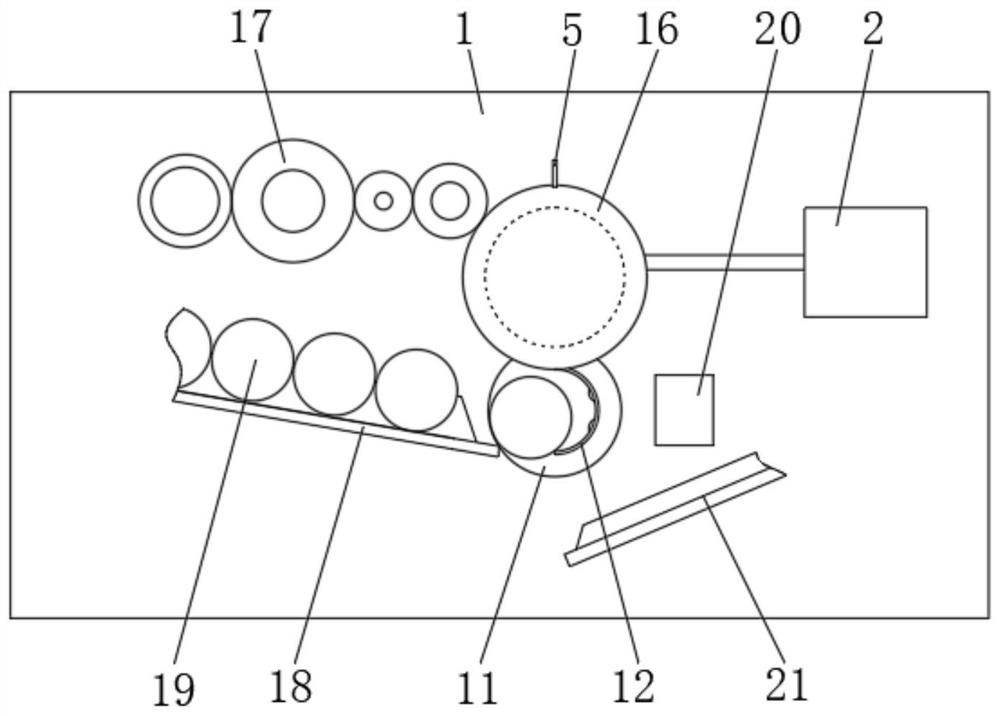

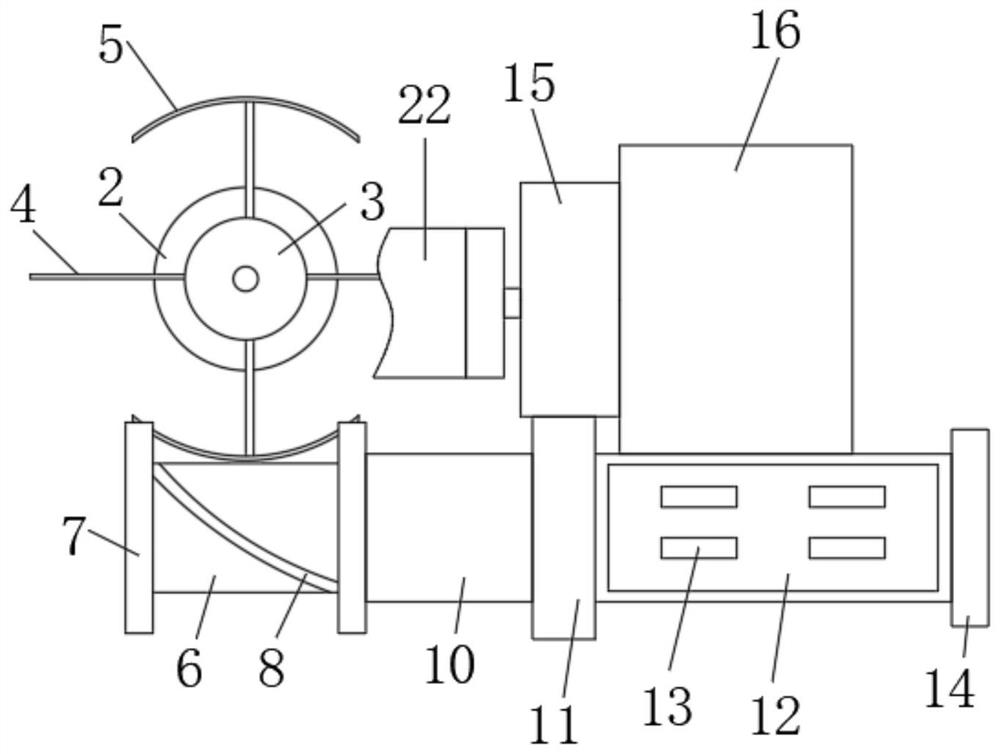

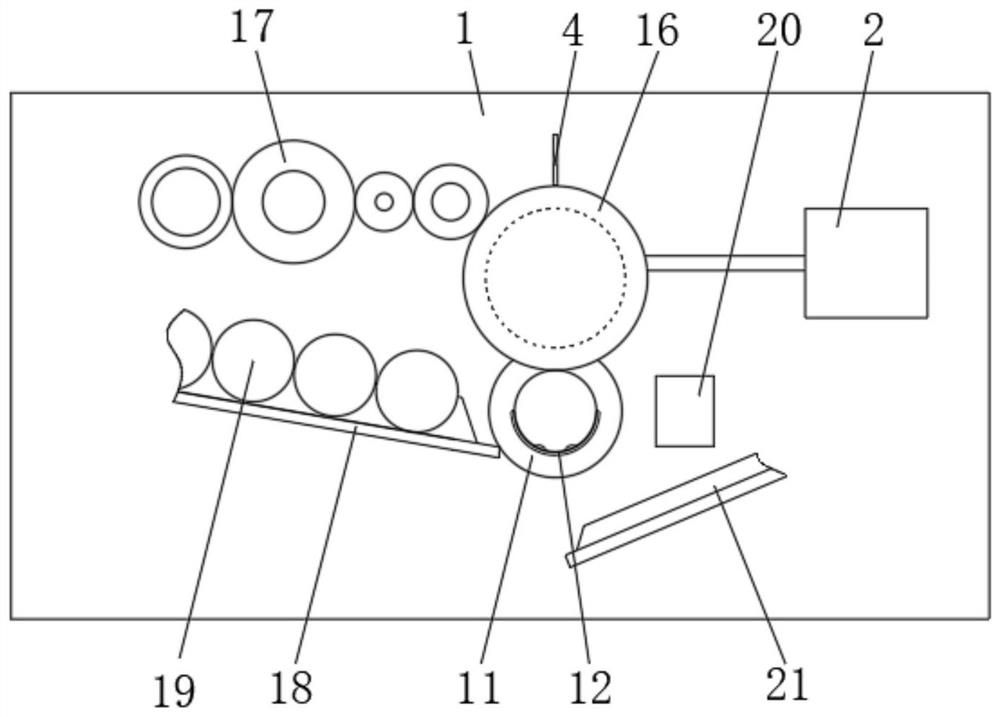

[0033] An ampoule bottle printing device, please refer to Figure 1 to Figure 5 , comprising: a fixed plate 1, a printing rubber roller 16 arranged to rotate relative to the fixed plate 1, a feeding device for conveying ampoules 19, a semi-cylinder 12 for receiving ampoules 19, and a semi-cylinder 12 for driving intermittently The first rotating transmission mechanism, the drying device used to dry the handwriting of the printed ampoule 19, the semi-cylinder 12 is connected to the printing rubber roller 16 through the second transmission mechanism, and the feeding device and drying device are set on the fixed plate 1 on.

[0034] The first transmission mechanism includes a toggle body and a passive body, the toggle body is connected with a motor 2 for driving the toggle body to continuously rotate, the continuous rotation of the toggle body can drive the passive body to rotate intermittently, and the passive body is directly or indirectly connected Half cylinder 12.

[0035]...

Embodiment 2

[0051] In this embodiment, the second transmission mechanism includes an upper sprocket, a chain and a lower sprocket, the upper sprocket is coaxially fixedly connected to the printing rubber roller 16, and one side of the lower sprocket is directly or indirectly coaxially fixedly connected to the side plate 7 , the other side of the lower sprocket is fixedly connected with the semi-cylinder 12, and the upper sprocket and the lower sprocket are connected by a chain. The intermittent rotation of the lower sprocket can drive the intermittent rotation of the upper sprocket. Other structures and principles are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0053] The second transmission mechanism adopts a belt drive, including an upper pulley, a belt and a lower pulley, the upper pulley is fixedly connected with the printing rubber roller 16 coaxially, one side of the lower pulley is directly or indirectly fixedly connected with the side plate 7, and the other of the lower pulley One side is fixedly connected with the semi-cylinder 12, and the upper pulley and the lower pulley are connected by a belt. Other structures and principles are the same as those in Embodiment 1 and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com