Extrusion extruder operating parameter automatic matching control system and control method

A technology of automatic matching and operation parameters, which is applied in the extrusion production field of extruders in the rubber industry, can solve problems such as high error rate, low efficiency, and poor extrusion dimensional stability, so as to reduce production costs, improve stability, and eliminate batches The effect of non-conforming products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

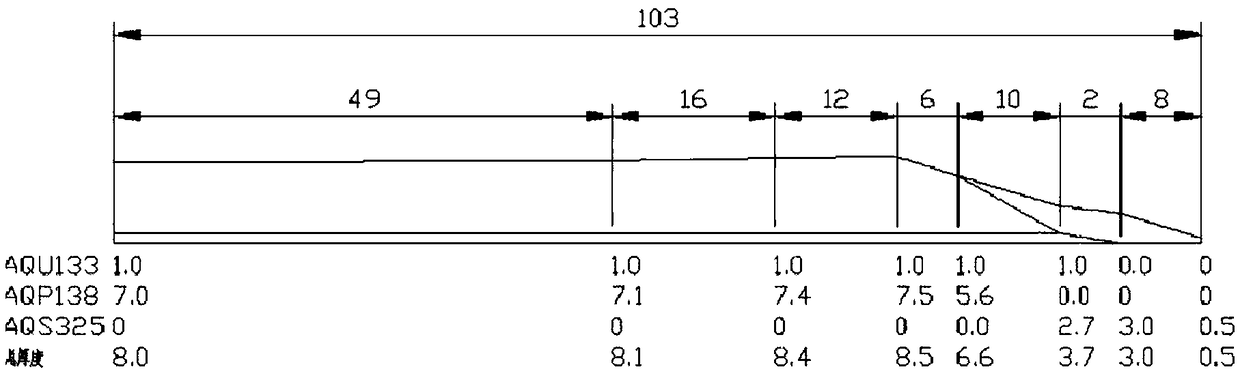

[0040] Embodiment 1, an automatic matching control system for extruder operation parameters, including MES system, extrusion equipment and PLC controller thereof, said extrusion equipment includes extruder and extrusion linkage line, said MES system Including the production operation database, integrating the standard production process parameters of the extruded products to realize the linkage production. The standard production process parameters include the screw speed of the extruder, the maximum speed of the linkage line, the extrusion width, the square width and the weight of the meter scale. The PLC controller is connected with the MES system to realize data communication, so as to obtain the standard production process parameters of the extruded product;

[0041] said

[0042] Among them, the area of the parts and the specific gravity of the rubber are based on the manufacturing instructions, the area of the parts is related to the thickness of the die plate and ...

Embodiment 2

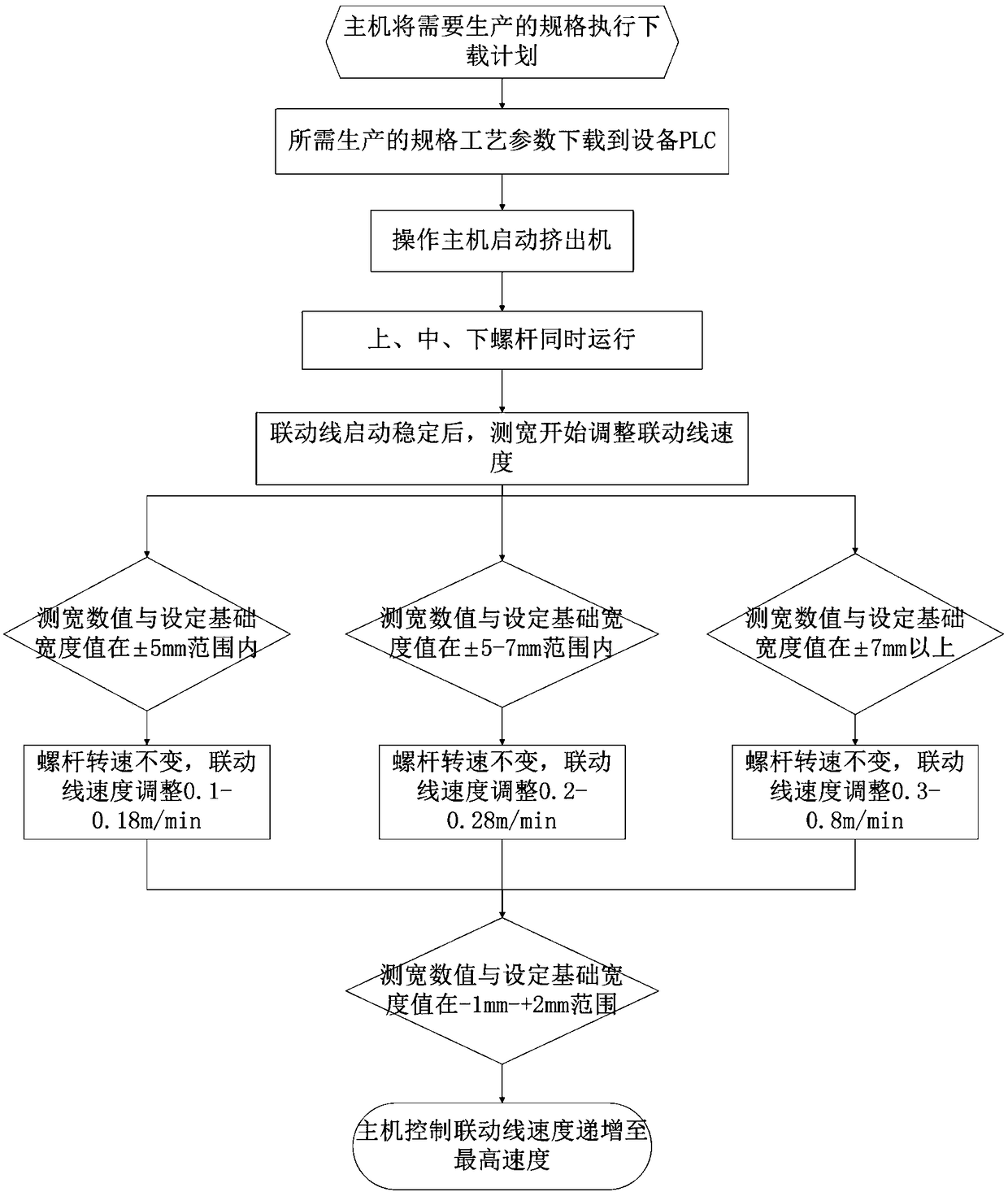

[0064] Embodiment 2, based on the control system proposed in Embodiment 1, this embodiment discloses an automatic matching control method for extruder operation parameters, including the following steps:

[0065] A. Obtain the specifications of the product to be extruded from the MES system, analyze and calculate the standard production process parameters of the product to be extruded, the standard production process parameters include extruder screw speed, maximum speed of linkage line, extrusion width, square Width and meter scale weight;

[0066] said

[0067] Wherein, see the construction standard for the area of the parts and the specific gravity of the rubber material, the area of the parts is related to the thickness of the die plate and the width of the die plate, the maximum speed of the linkage line is the maximum speed specified in the equipment technical agreement, and the correction coefficient is The ratio of the initial glue output of the equipment to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com