High-precision die stamping device

A stamping device, high-precision technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as unsatisfactory, inconvenient, and inability to ensure compliance with requirements, and achieve good results and easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

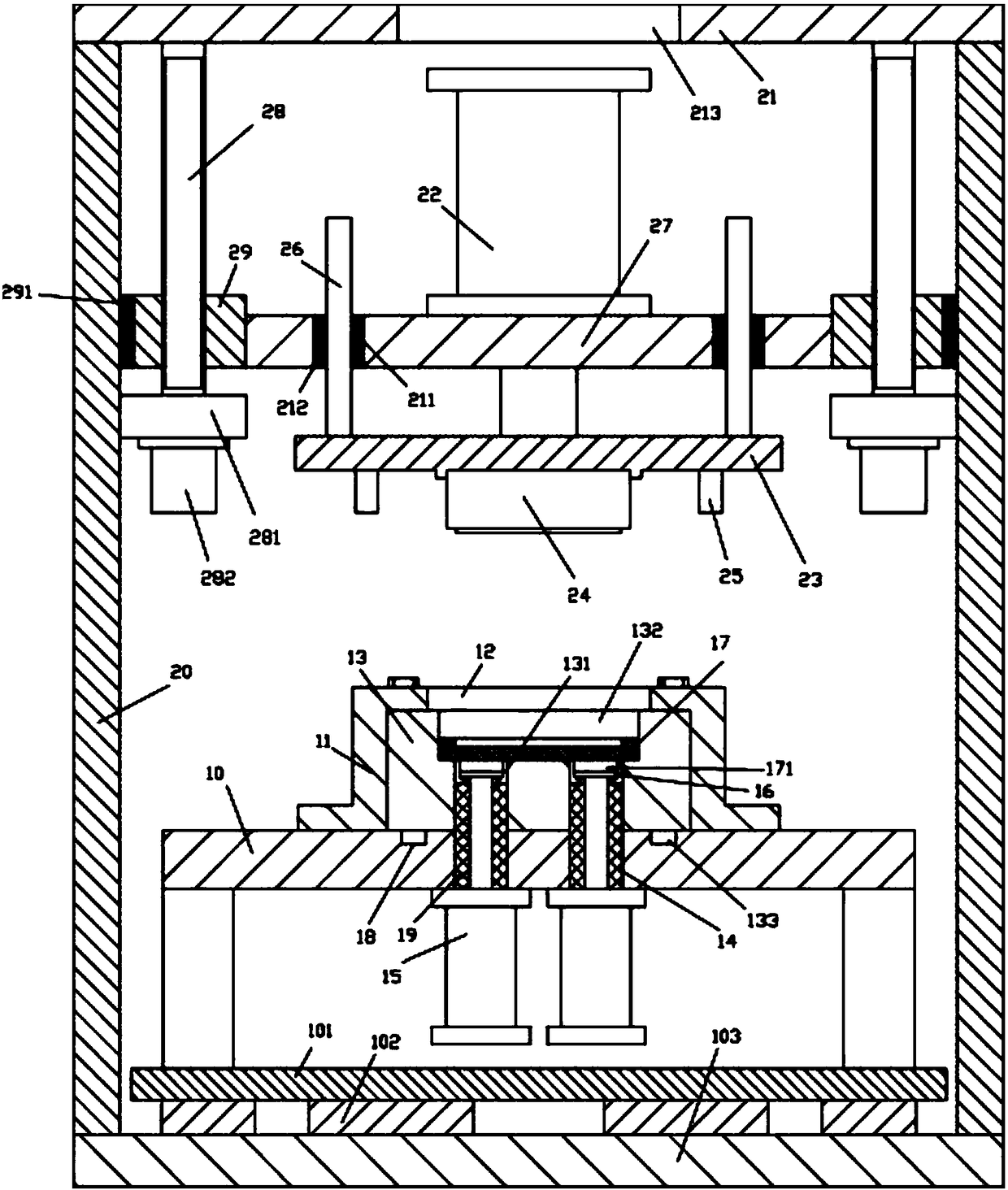

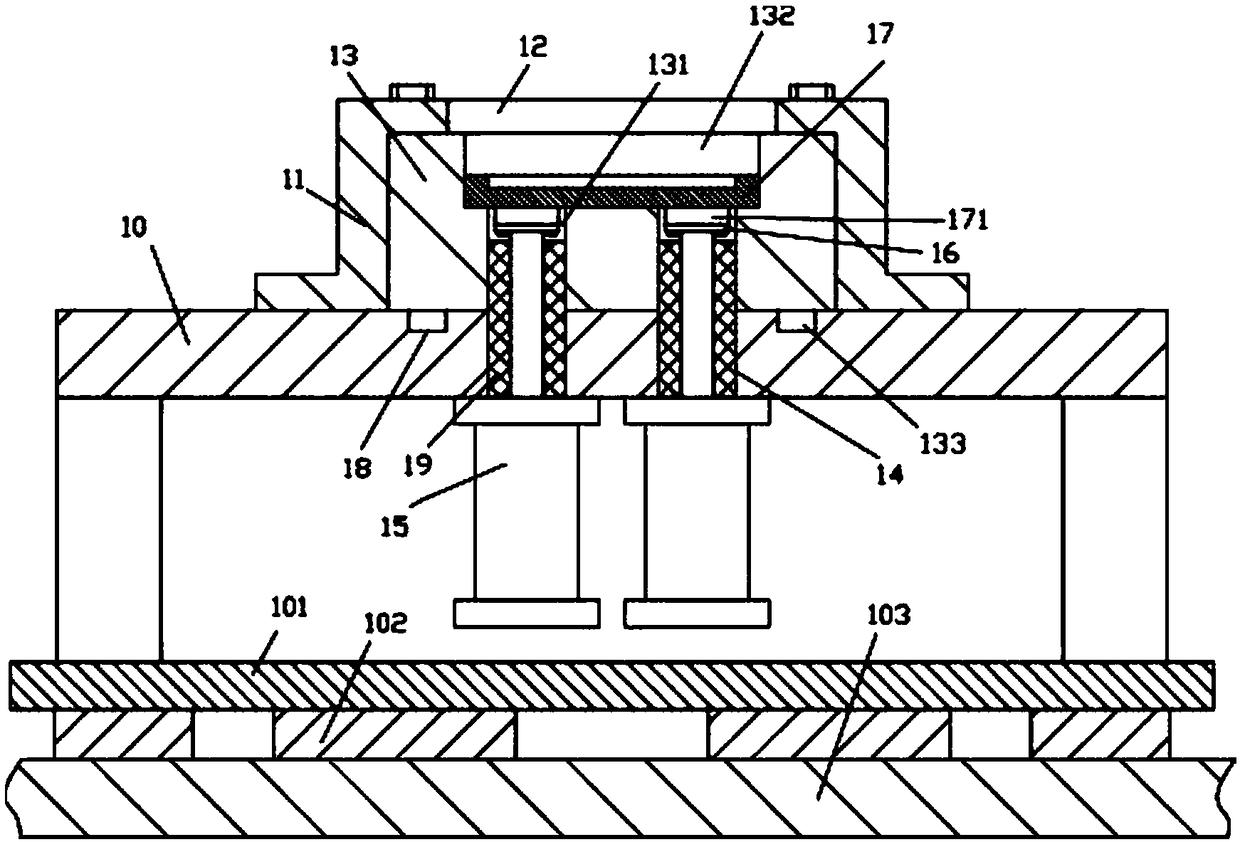

[0021] Examples, see e.g. Figure 1 to Figure 2 As shown, a high-precision die stamping device includes a frame 10, the bottom of the frame 10 is provided with a main base plate 103, and the left and right sides of the top surface of the main base plate 103 are fixed with main vertical plates 20, supported The top plate 21 is fixed on all the main vertical plates 20, the main lifting plate 27 is directly below the supporting top plate 21, and the upper punching oil cylinder 22 is fixed on the middle part of the top surface of the main lifting plate 27, and the push rod of the upper punching oil cylinder 22 passes through The bottom surface of the main lifting plate 27 is fixed with an upper mounting plate 23, and the middle part of the bottom surface of the upper mounting plate 23 is fixed with an upper mold block 24;

[0022] The left and right sides of the bottom surface of the upper top plate 21 are hinged with the top of the vertical adjustment screw 28 through bearings, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com