Continuous bubble scraping type multilayer inflatable bottom transmission type flotation machine

A flotation machine and transmission technology, applied in flotation, solid separation, etc., can solve the problems of secondary sedimentation of mineralized particles, foam stagnation, etc., achieve the effect of stable liquid level, prevent secondary sedimentation, and reduce the radius of bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

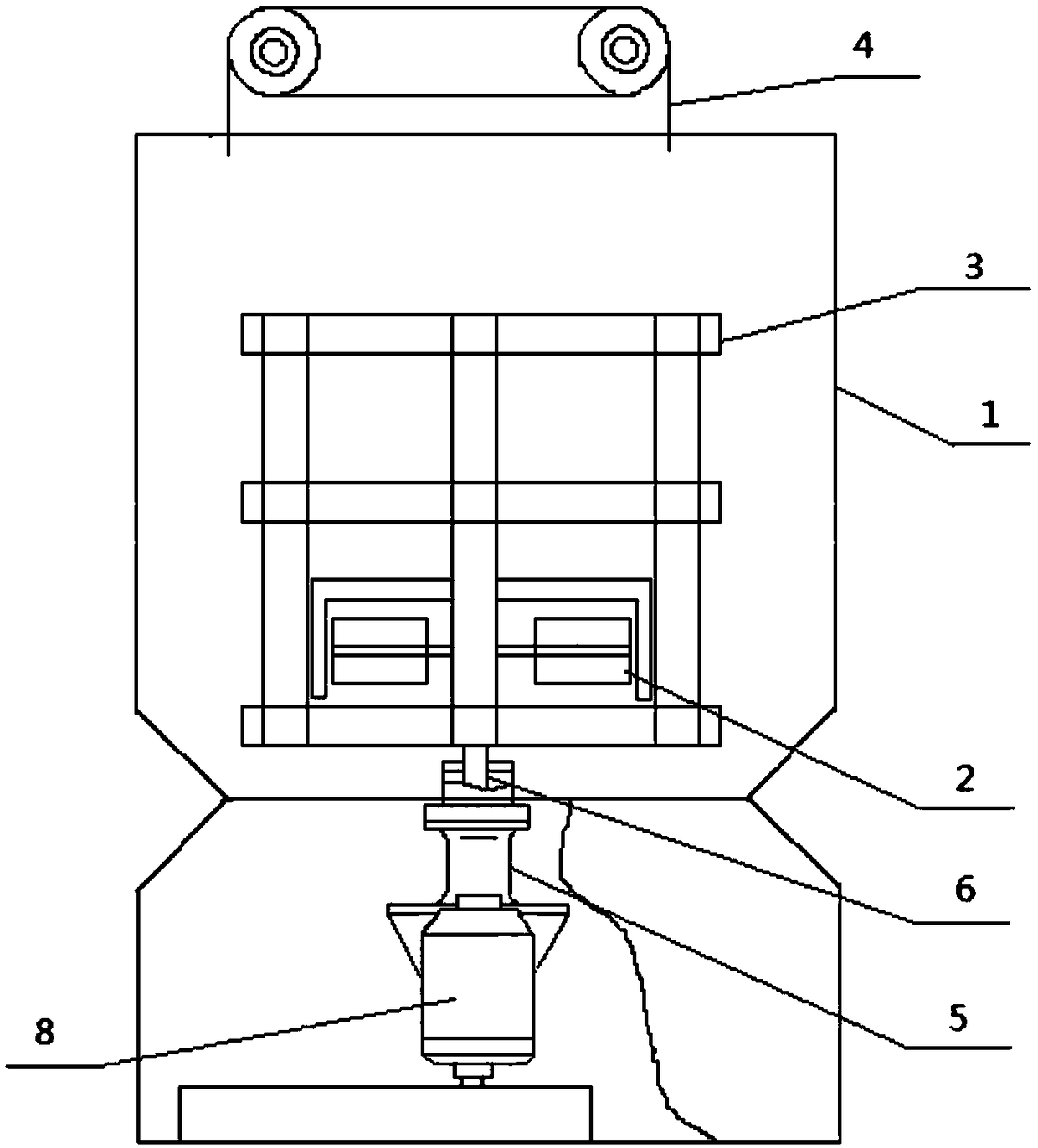

[0026] refer to figure 1 , figure 2 and image 3 , the present invention is a continuous bubble-scraping multi-layer inflatable bottom-driven flotation machine, including a flotation cell 1, a mechanical stirring device 2, a ring-column microbubble generator 3 and a bubble-scraping device 4 are arranged inside the flotation cell 1.

[0027] The cross-section of the cell body of the flotation cell 1 is rectangular, and a row of ore openings are opened on the side of the lower part. There is a round hole in the center of the bottom of the tank body, and the round hole is provided with a hollow vertical center tube 5. The flotation machine shaft 6 is set in the center tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com