Cable insulation sheath annular cutting device capable of preventing copper core wire from being cut and broken

A technology of insulating sheath and copper core wire, which is applied in the direction of cable installation device, cable installation, dismantling/armored cable equipment, etc., and can solve the problems of copper core wire damage, cutting, cutting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

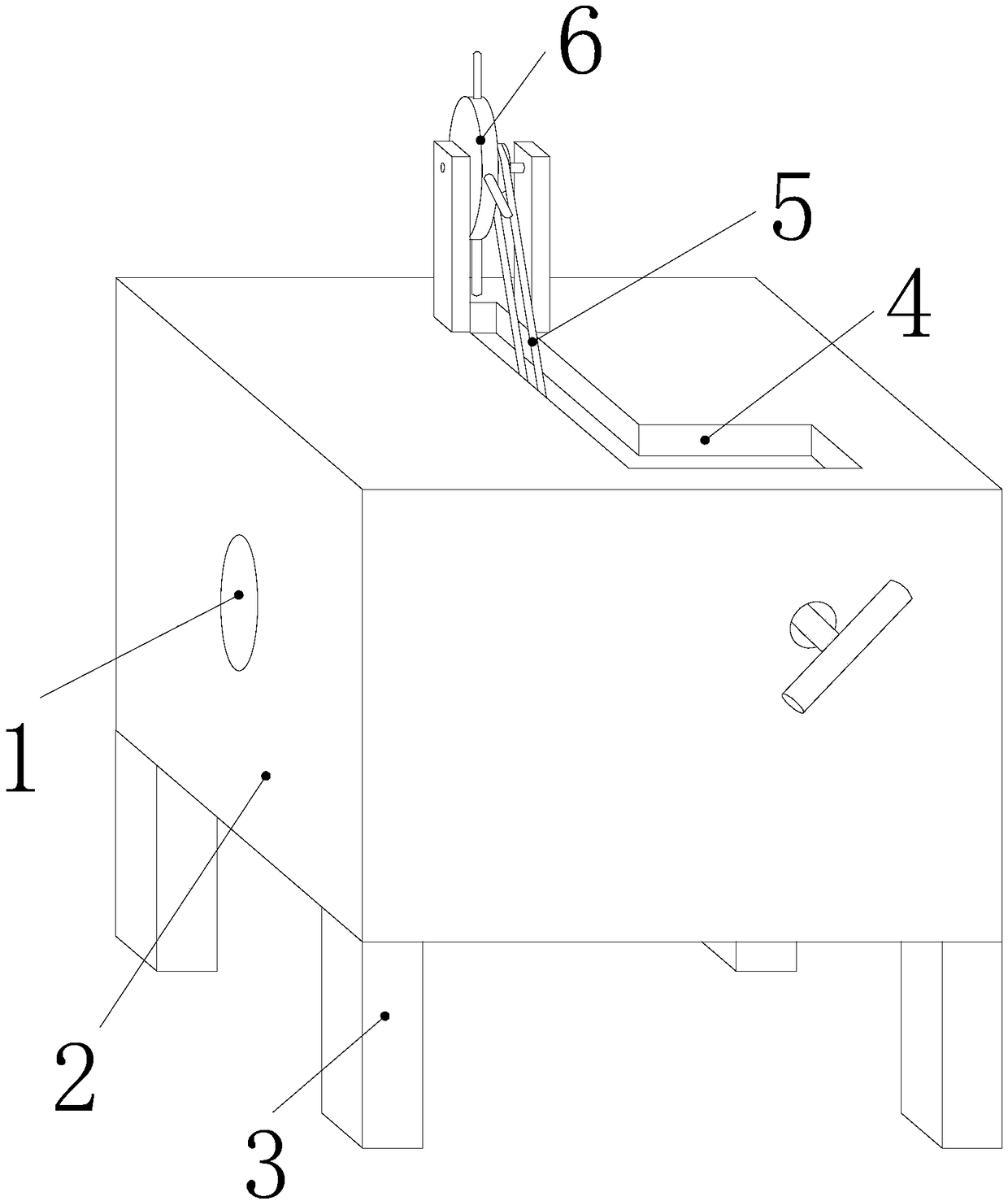

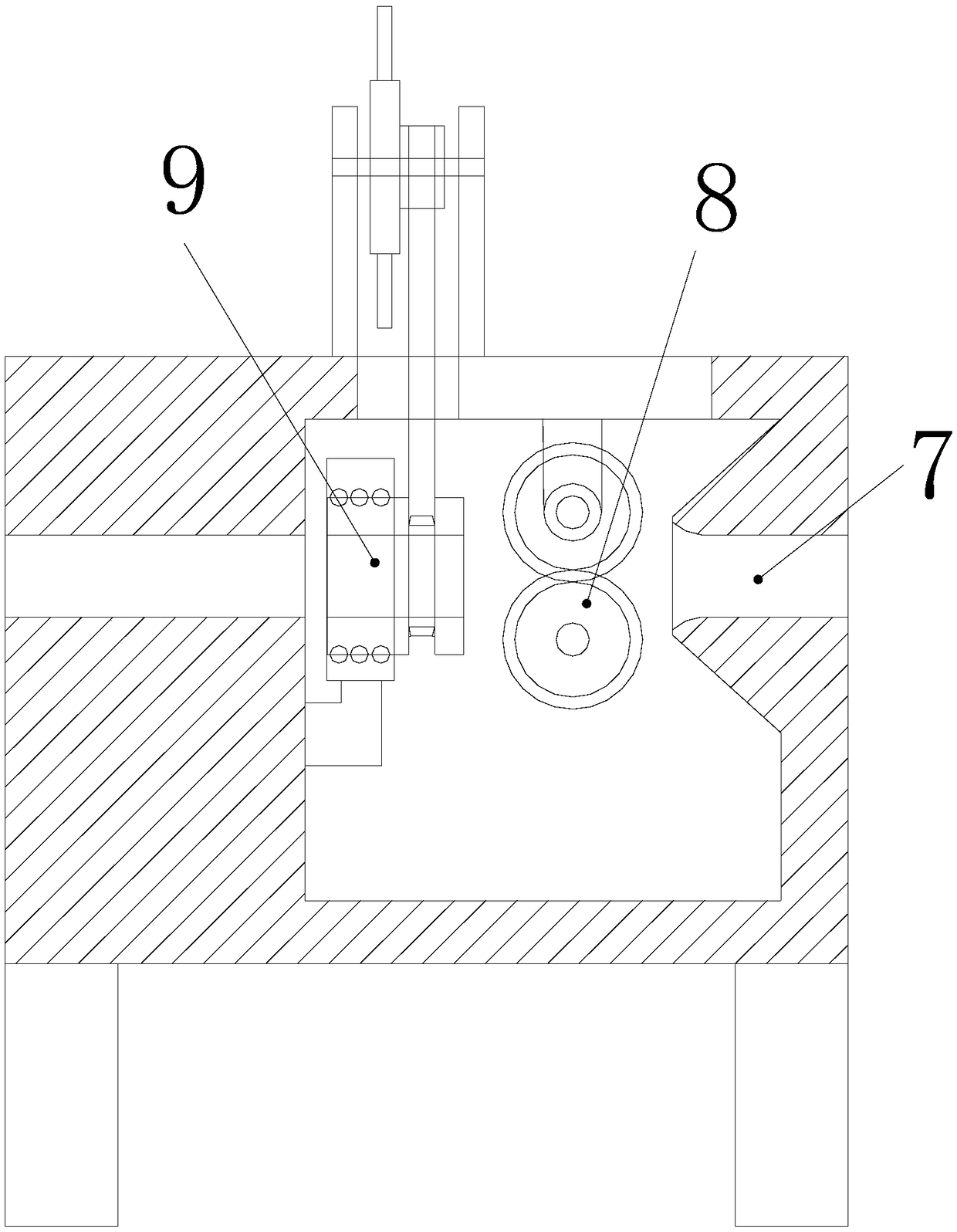

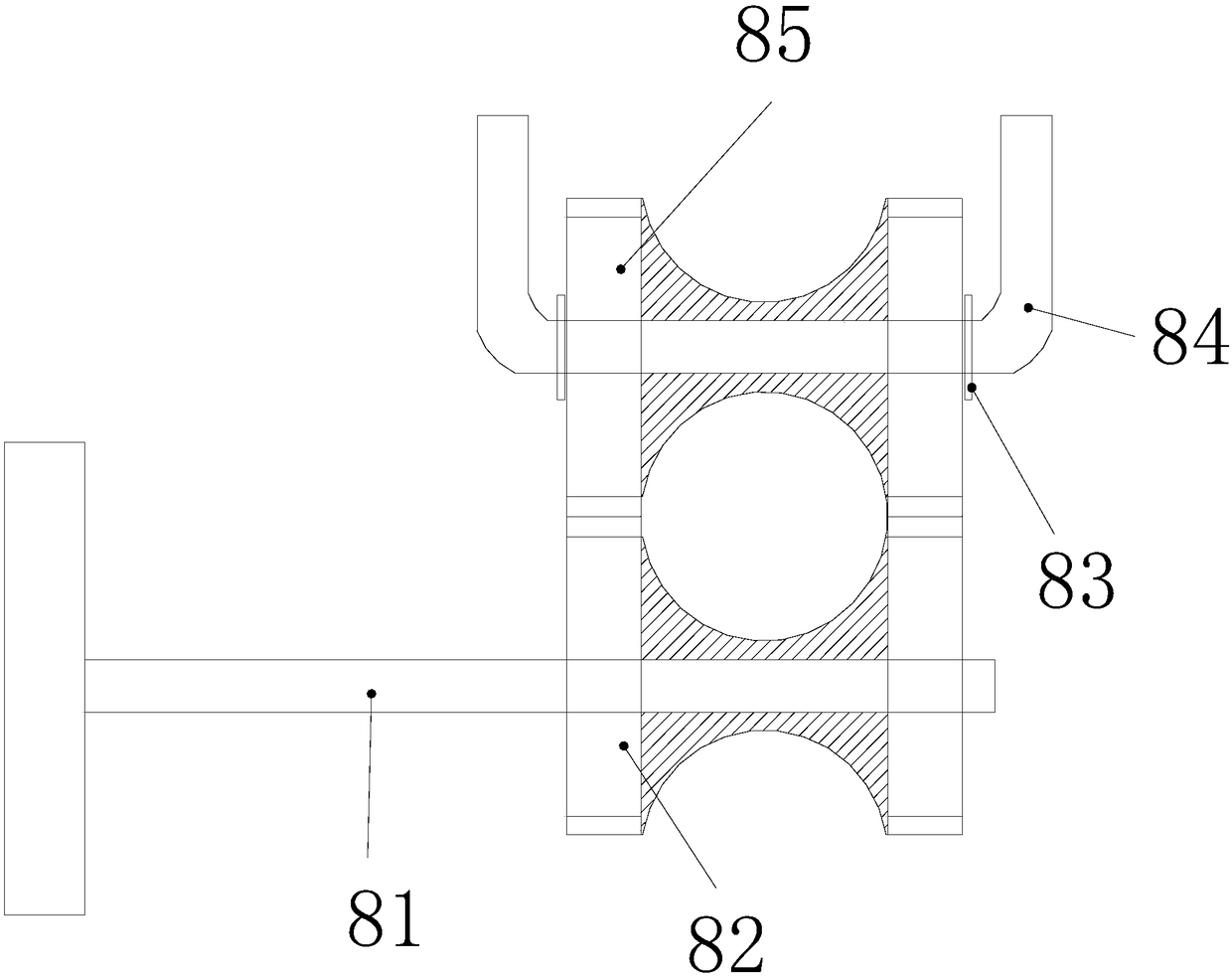

[0028] see Figure 1-Figure 2 , the present invention provides a cable insulation sheath ring cutting device for preventing copper core wires from being cut and broken: its structure includes a cable inlet 1, a box body 2, a tripod 3, an L-shaped slot 4, a belt 5, and a pulley 6 , cable outlet 7, sheath axial peeling mechanism 8, copper core wire non-destructive circumcision mechanism 9, the cable inlet 1 is embedded in the left surface of the box body 2, and the tripod 3 is provided with more than two and respectively Welded on the four corners of the lower surface of the box body 2, the L-shaped slot 4 is embedded in the upper surface of the box body 2, the pulley 6 is movably connected to the rear end of the upper surface of the box body 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com